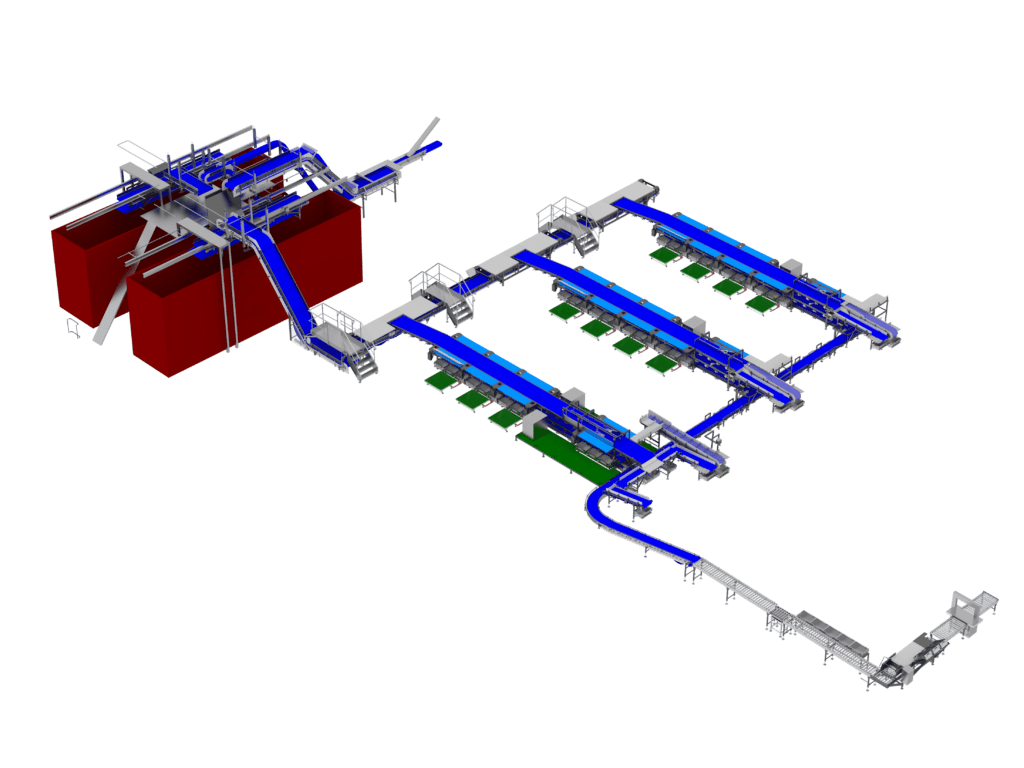

Cutting Workshop – Beef

At Acemia, we are committed to providing meat cutting solutions that meet your most demanding needs. Our cutting lines ensure maximum efficiency and unparalleled quality at every step of the process. Our comprehensive solutions include deboning, trimming, and peeling stations.

Together, we ensure efficient waste management and quality meat production.

Enhance Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors,…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools.

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Deboning

With our cutting stations specially designed for this stage, operators precisely cut the front and rear portions of beef. Then, conveyors evacuate the bones to dedicated waste bins, also separating meat residue and gelatin for further use.

Trimming

Trimming separates the muscles from the beef after deboning on the table. Operators sort and recover less noble pieces for hamburger production.

Subsequently, ergonomic trimming stations eliminate excess fat and undesirable waste from the beef piece, ensuring optimal quality.

End of Line

The meat passes through a peeling station designed to remove any excess skin surrounding the muscle, ensuring a flawless final product.

The muscles are carefully grouped and directed to vacuum packaging systems, preserving their freshness and quality. Trimmings, on the other hand, are destined for reuse in ground meat preparation, while waste is evacuated to dedicated bins, thus contributing to efficient residue management.

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSDs) associated with repetitive tasks in the food industry.

We understand that your commitment to the safety and health of your employees is essential for creating high-quality products. That’s why our unpacking stations are designed to minimize the risk of MSDs and improve the safety of your operators. Our experts have developed true expertise in designing cutting-edge equipment to preserve the safety of your operators while ensuring superior production quality. Our unpacking stations are equipped with ergonomic devices that help your operators work comfortably and efficiently. To do this, we integrate custom height-adjustable equipment into our solutions, providing optimal working height and radius.