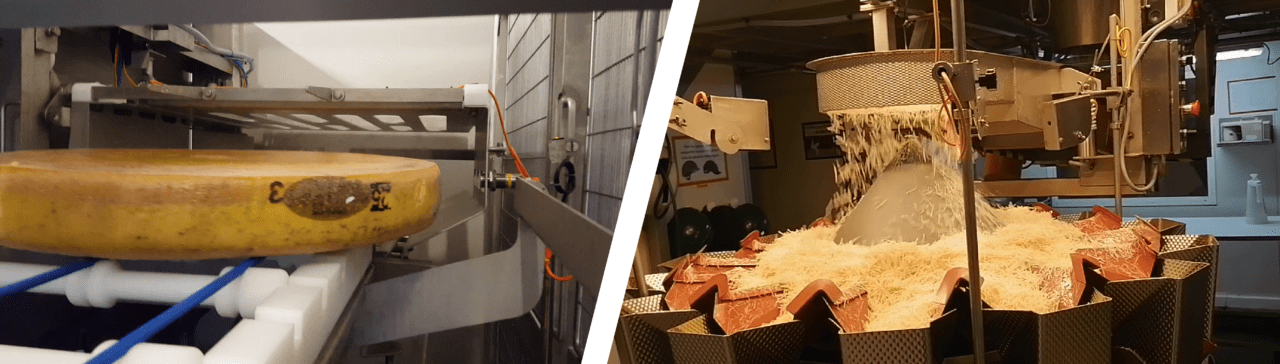

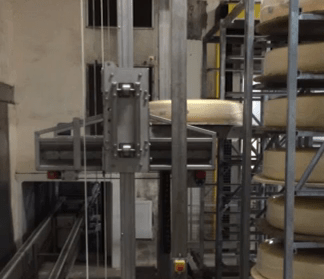

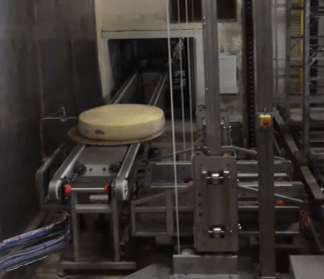

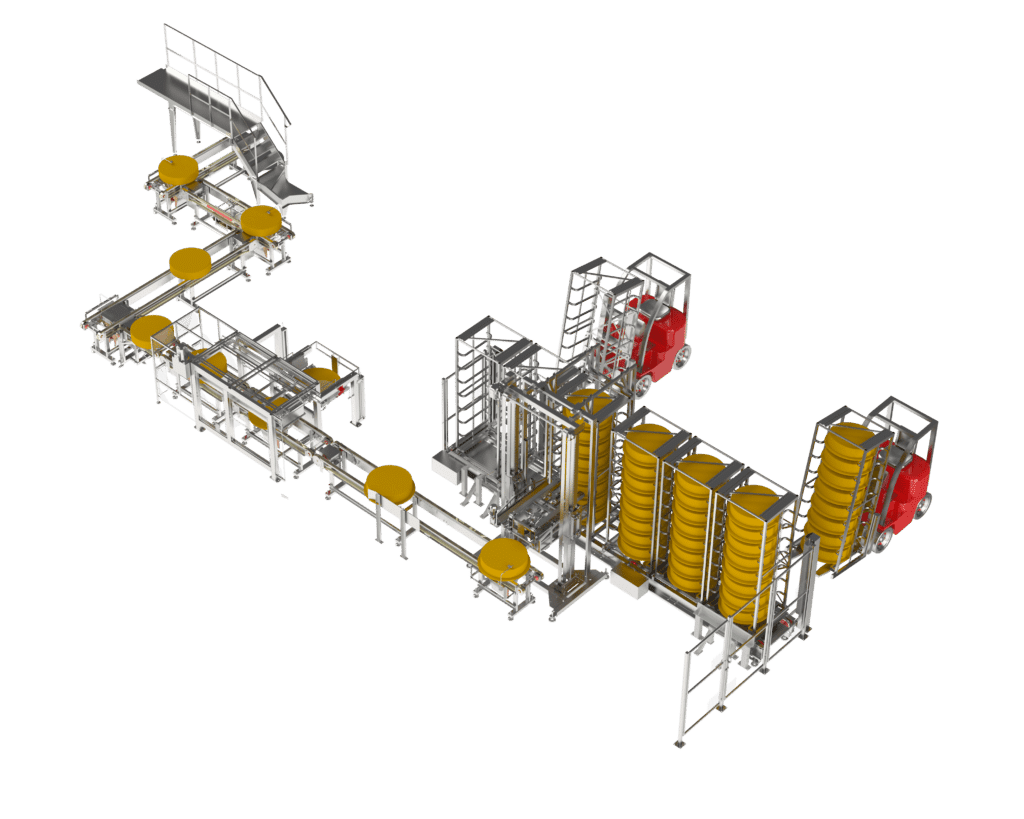

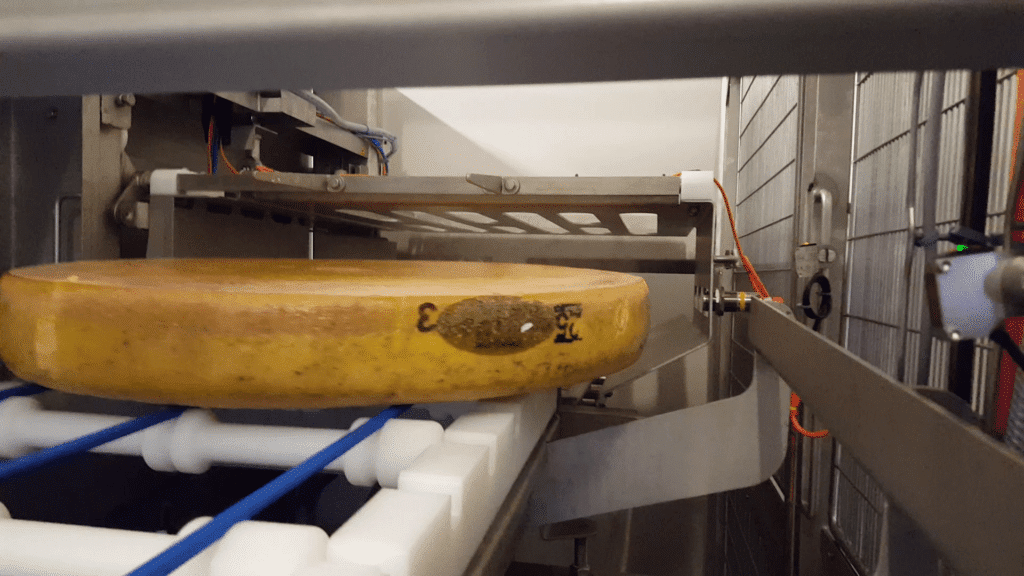

Acemia has developed a complete solution for handling and managing your wheels of cheese. Trolleys load the wheels of cheese, which are then transferred to the next stage of the process via an unloading lift. The wheels are then directed to a system for removing the ripening boards.

Our solutions guarantee the quality and safety of your cheese while maximizing your production.

Our cheese lines can be adapted to the specific characteristics of your products (size, fragility, etc.), your available space, your number of workstations, etc.

Improve Your Machine Availability With Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors, reducers, sensors,…)

Hygienic Design+ finish:

Microblasting (ra : 6,4)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

Removal of belts and accessories without tools.

Storage cart available on request

ZERO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow tubings on all our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Optimize Your Production with a Customized Solution

Ensure optimum productivity and efficiency with our cheese lines. Our solutions are tailor-made to meet the specific needs of each company, offering personalised management of cheese wheels right through to the final packaging of your products.

Our trolleys ensure that the wheels of cheese are loaded safely and efficiently, ensuring smooth transport to the next stage of the process.

Once loaded, the wheels are transferred to the next stage via an unloading lift, ensuring controlled movement to the next stage of the process. Then, a dedicated system allows the refining boards to be removed, preparing the wheels for the next stages of production or maturation.

Our solutions are flexible and can be adjusted to the speed of your production lines. We adapt our solutions to your specific needs and constraints, such as the number of workstations, available space, production rate, product sizes, etc.

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSDs) associated with repetitive work in the food industry.

We know that your commitment to the health and safety of your employees is essential to creating high-quality products. That’s why all our lines are designed to minimise the risk of RSI and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing high-quality production. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To achieve this, we incorporate bespoke height-adjustable equipment into our solutions, offering optimum height and working radius.