Primary Packing

Primary packaging plays an essential role in preserving food safety. Our primary packing solutions ensure the quality and conformity of your products.

Our primary packaging solutions help protect your food from contaminants such as dirt, bacteria and moisture. This helps maintain the quality, freshness and wholesomeness of your food throughout its life cycle, from production to consumption. Our solution combines delicacy and efficiency to respect the integrity of your products and maximize your production.

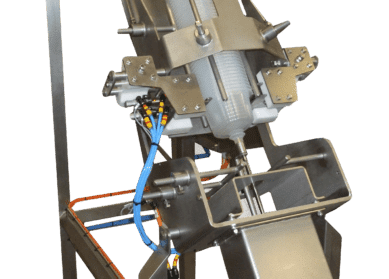

Improve Your Machine Availability with Our Hygienic Design

As food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, sensors, etc.)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

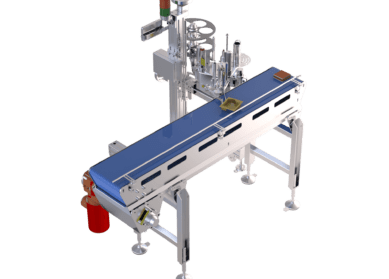

EASY TO CLEAN

Ground level equipment for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and sloped structure to avoid retention zones

No hollow tubings on all our equipment

WATER AND SANITATION PRODUCTS SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

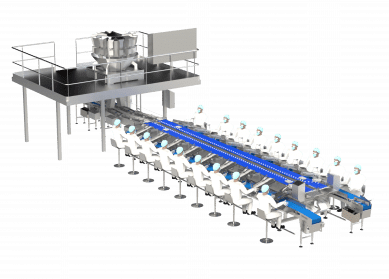

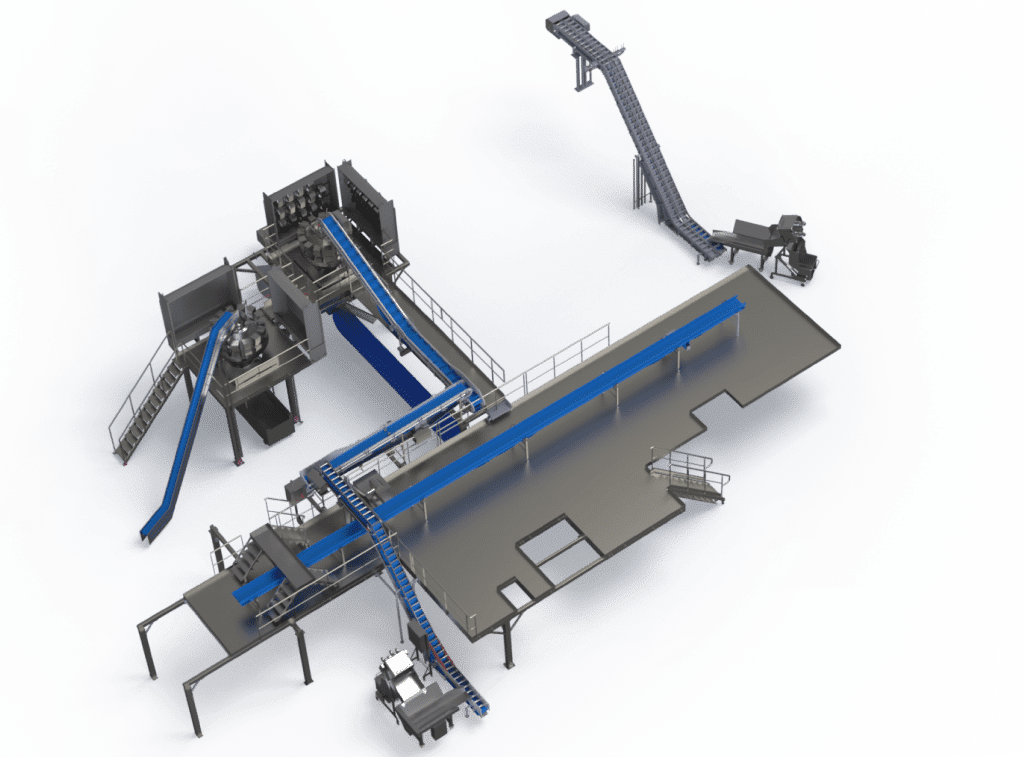

Optimize Your Production with a Customized Solution

Optimize your productivity and efficiency with our customized primary packaging solutions. Designed to meet the specific needs of your business, our weighing and control solutions guarantee optimized production operations.

Our primary packaging solutions are perfectly adapted to your different product and packaging types. By combining delicacy and efficiency, we preserve the integrity of your products while maximizing your production capacity. Whatever the speed of your lines, our solutions are tailored to your specific needs and constraints, such as number of stations, available space, speed, raw or frozen products, and product sizes.

Our engineers and technicians work closely with you to understand your constraints, needs and production objectives. They also assess your working environment and existing equipment to design a customized solution that perfectly meets your expectations.