The demand for snacking is growing all the time. These products are varied, and you need to produce a multitude of recipes to meet your customers’ demands. From one product to another, production processes and flows are not identical. These differences can be demanding for your production site and your operators. Between each recipe, your operators have to spend a considerable amount of time cleaning, without guaranteeing food safety.

Acemia is involved in all areas of snacking, from sandwich-making and sandwich-folding to aperitif cookies.

Improve Machine Availability with our Hygienic Design

Acemia operates in the ready meals sector, in France and abroad, for both unpacked and packaged products. We can help you improve your production processes, from food preparation to tray placement and primary packaging. We offer automated handling solutions adapted to your products and their preparation.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, reducers, sensors, etc.)

Hygienic Design+ finish:

Bead-blasted (ra: 6.4)

Easy to clean

Man-height equipment for easy access, inspection and cleaning.

Tool-free removal of belts and accessories.

Storage cart available on request

NO WATER RETENTION

Open, inclined structure to avoid retention zones

No hollow tubings on any of our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures perfect cleaning of all parts in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Improve Your Operators’ Performance with Safe & Ergonomic Workstations

We understand the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the health and safety of your employees is essential to creating high-quality products. That’s why all our lines are designed to minimize the risk of RSI and improve operator safety. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work in complete safety, while guaranteeing top-quality production. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To this end, we integrate customized height-adjustable equipment into our solutions, offering optimum height and working radius.

Optimize Your Production with a Customized Solution

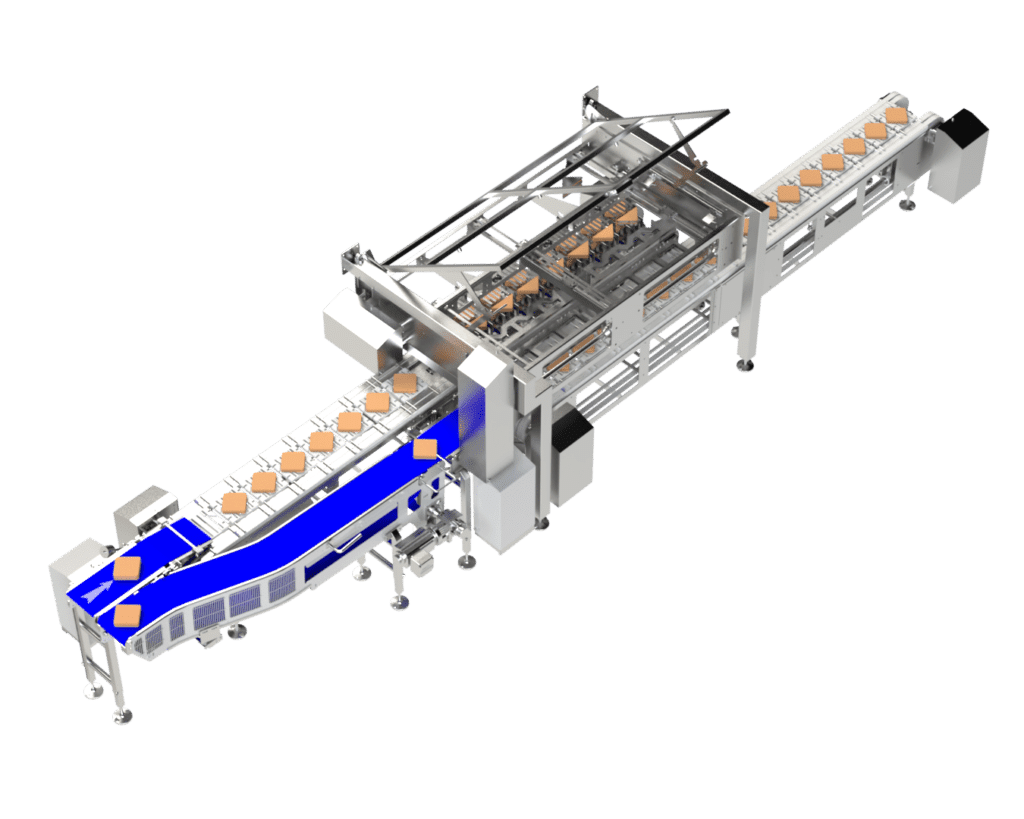

Acemia operates in the snacking sector, in France and abroad, for both plain and packaged products. We can help you improve your production processes, from dough preparation and baking to primary packaging. We offer automated transitic solutions adapted to your products and their preparation.

Thanks to the close relationship between our engineers, our sales staff and our customers, we can help you develop a calibrated, high-quality technical project that meets all your requirements…

Integrate Robotized Equipment

Acemia designs robots to offer you unrivalled production flexibility. and respond to changing production needs, whether in terms of recipes, products or containers.

Extremely versatile, this robot can be used in a multitude of industrial applications.

These robots are capable of assisting in a variety of production tasks, such as loading additional ingredients into trays, carton packs, thermoforming machines and much more. Thanks to their adaptability and efficiency, these robots are valuable allies in optimizing your production processes reliably and efficiently.