Cutting Workshop

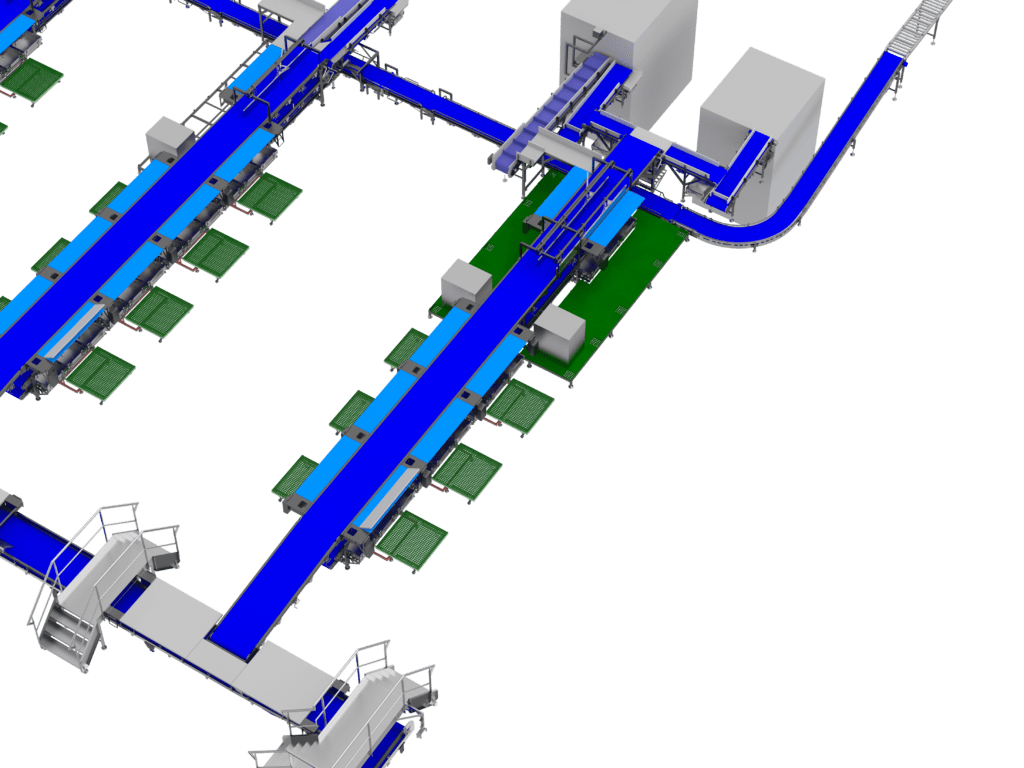

At Acemia, we are committed to providing meat cutting solutions that meet your most demanding needs. Our cutting lines ensure maximum efficiency and unparalleled quality at every step of the process. Our comprehensive solutions include deboning, trimming, and peeling stations, ensuring optimal quality at each stage.

Together, we ensure efficient waste management and quality meat production.

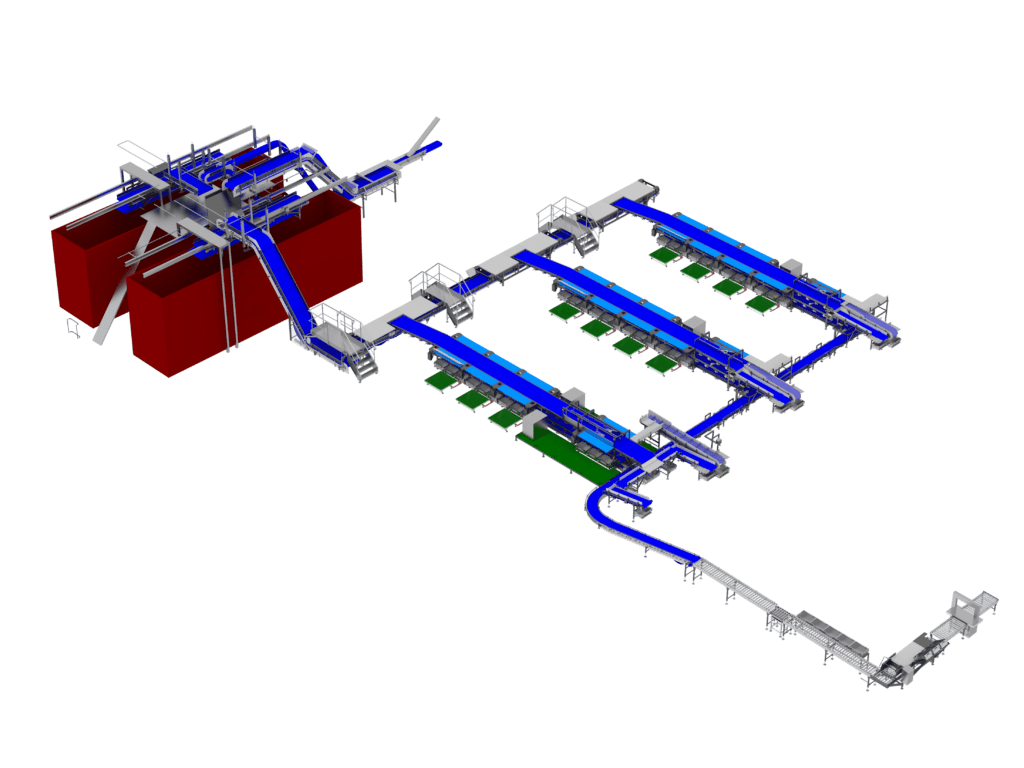

Cutting Workshop: Beef

Deboning

With our cutting stations specially designed for this stage, operators precisely cut the front and rear portions of beef. Then, conveyors evacuate the bones to dedicated waste bins, also separating meat residue and gelatin for further use.

Declumping

Muscle separation allows the separation of muscles from the beef cut after deboning on the table. Operators sort and collect the less valuable pieces for ground beef production.

Trimming

Subsequently, ergonomic trimming stations eliminate excess fat and undesirable waste from the beef piece, ensuring optimal quality.

Muscle Peeling

The meat passes through a peeling station designed to remove any excess skin surrounding the muscle, ensuring a flawless final product.

The muscles are carefully grouped and directed to vacuum packaging systems, preserving their freshness and quality. Trimmings, on the other hand, are destined for reuse in ground meat preparation, while waste is evacuated to dedicated bins, thus contributing to efficient residue management.

Cutting Workshop: Pork

Arrival of Piglets

The meat quarters are carried along a hook rail for their transportation.

Trimming

A bidirectional pedal conveyor is placed at the saw level. Subsequently, trimming stations will allow the removal of undesirable waste from the pork piece, ensuring optimal quality.

Packaging

Flowpack packaging on three sides provides complete protection of the product, ensuring its freshness and integrity during transportation and storage.

Vacuum sealing the product in a dedicated chamber eliminates air, thus extending shelf life and preserving taste and nutritional quality.

Vacuum-sealing the fillets (Cryovac) with a water jet reduces the space occupied by the product in the packaging, promoting more efficient storage and maintaining aesthetic appearance while enhancing preservation.

Piece Sorting

The products are realigned for optimization of conveyor widths to ensure efficient unit flow.

Products are dried using an air blade located below and above them, in a dedicated drying tunnel.

At the dryer exit, a positioning and handling device lifts the products, allowing for their pacing and weighing.

Piece sorting is done according to their weight using a fork per track, ensuring precise quality and packaging control.

Improve Your OEE with Our Hygienic Design

As a food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the health and safety of your employees is essential to creating high-quality products. That’s why all our lines are designed to minimise the risk of RSI and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing high-quality production. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To achieve this, we incorporate bespoke height-adjustable equipment into our solutions, offering optimum height and working radius.