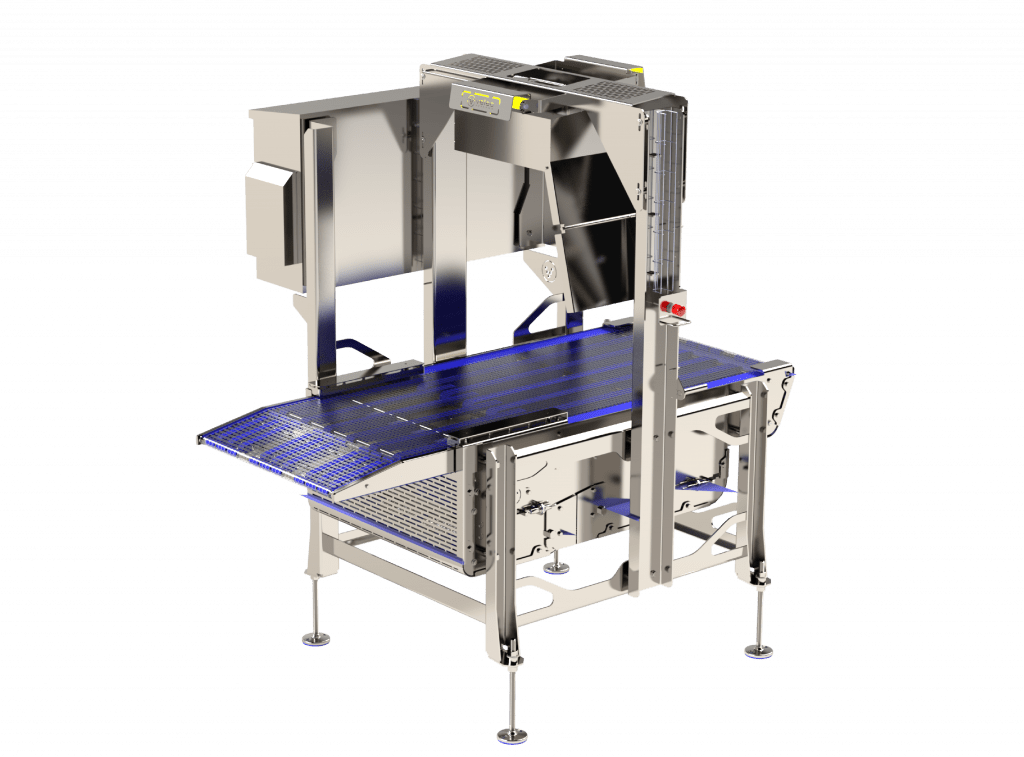

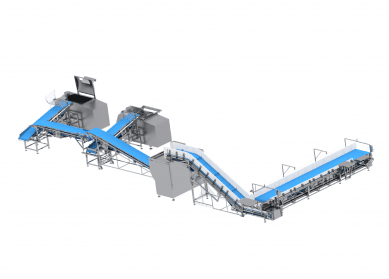

Shuttle Conveyor

Retractable conveyors can be used on production lines to redirect products from one conveyor line to another, and to regulate production rates.

In production systems where different steps require different processing times, retractable conveyors can be used to deposit products in a precise way and to optimize the loading of certain equipment (oven, freezer…)

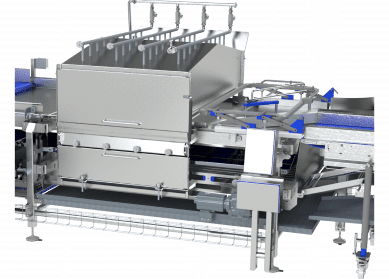

Designed to minimize retention areas, hollow bodies and rough surfaces where bacteria can grow, conveyors are easy to clean and disinfect, reducing the risk of cross-contamination.

Often placed upstream of your freezer or oven, they allow you to maximize your production thanks to a perfect alignment of your products through a retractable conveyor system.

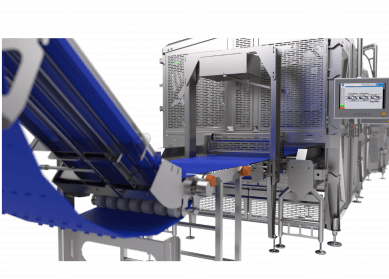

Improve Your Machine Availability with Our Hygienic Design

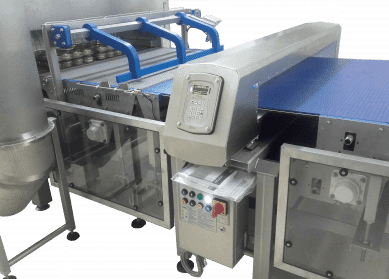

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

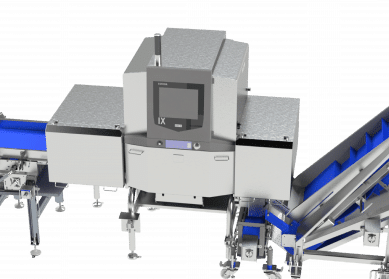

Maximize Your OEE with Our Shuttle HD+ Conveyors

Our shuttle hygienic design conveyors are constructed from hygienic and corrosion resistant materials, reducing the risk of food contamination and the costs associated with regulatory non-compliance.

They are designed to be easily disassembled and cleaned, which significantly reduces the time required for cleaning and maintenance. This reduces downtime for cleaning and maintenance, which in turn increases conveyor uptime.

Minimize product loss and downtime and improve efficiency with our HD+ conveyors.

By equipping yourself with an Acemia hygienic design conveyor system, you ensure food safety in your plant, reduce your cleaning time and increase your machine availability!

Your productivity is improved and your customers are satisfied!