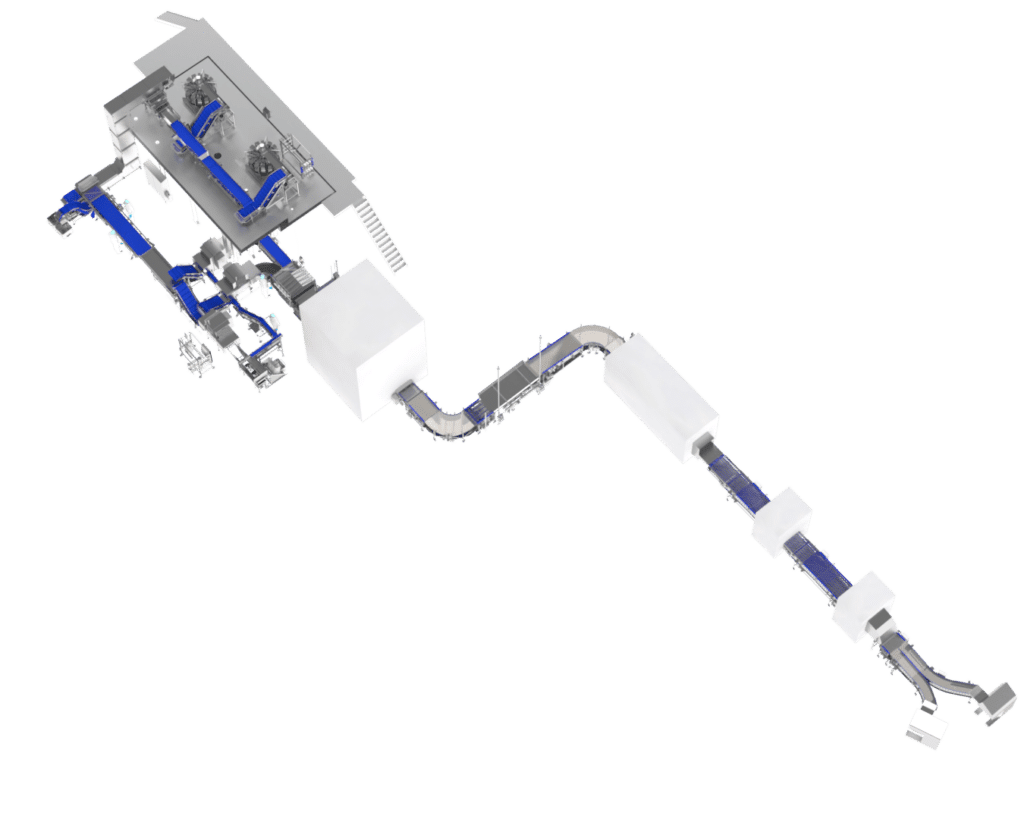

Because each breaded products producer has its own plant, with its own constraints and product specificities, Acemia designs the best solution to streamline your nugget production process. We can help you improve your production process from frying to deep freezing of processed products and cartonization of the primary packaging.

Ensuring food safety while being productive is one of your priorities. The hygiene and cleanability of your lines are therefore essential elements to deliver your orders and satisfy your customers.

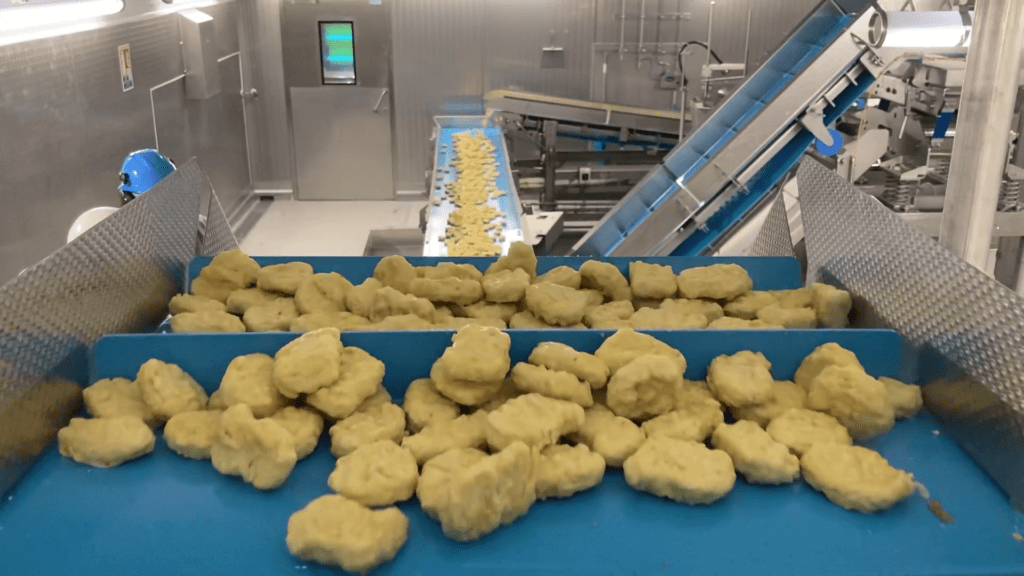

Our complete frozen nugget production line offers an integrated solution, from the continuous industrial fryer to the packaging. We are committed to providing you with superior equipment, optimal efficiency and reliable results. Trust our expertise to produce the nuggets that will delight your customers.

Your operators have to work in a cold and humid environment to perform repetitive tasks with high MSD risks.

Unpacking Station

Help your operators to unpack your cartons safely and efficiently with our unpacking stations. Your operators can work at a constant level, thanks to a sensor that automatically adjusts pallet height.

Forming Machine Loading

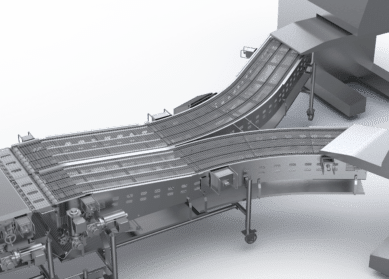

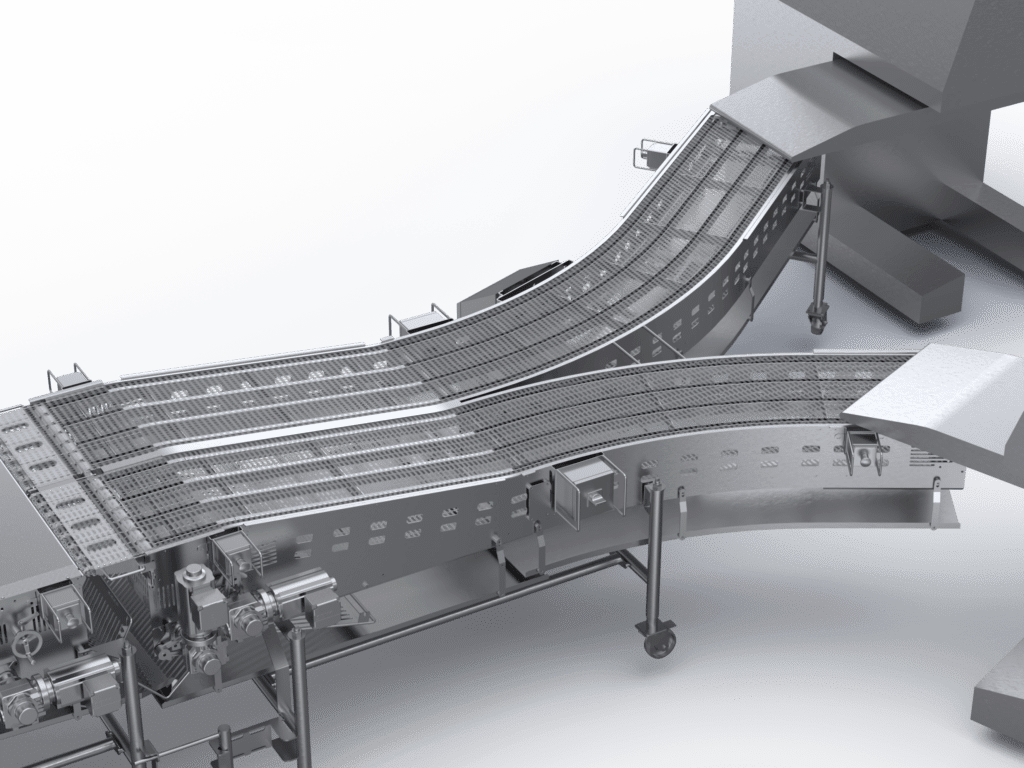

Acemia transfers your products between the breading machine and the flouring machine using stainless steel mesh conveyors.

These belts are often used on conveyors operating at high temperatures or in corrosive environments. Easy to clean and disinfect, they are ideally suited to demanding hygiene environments.

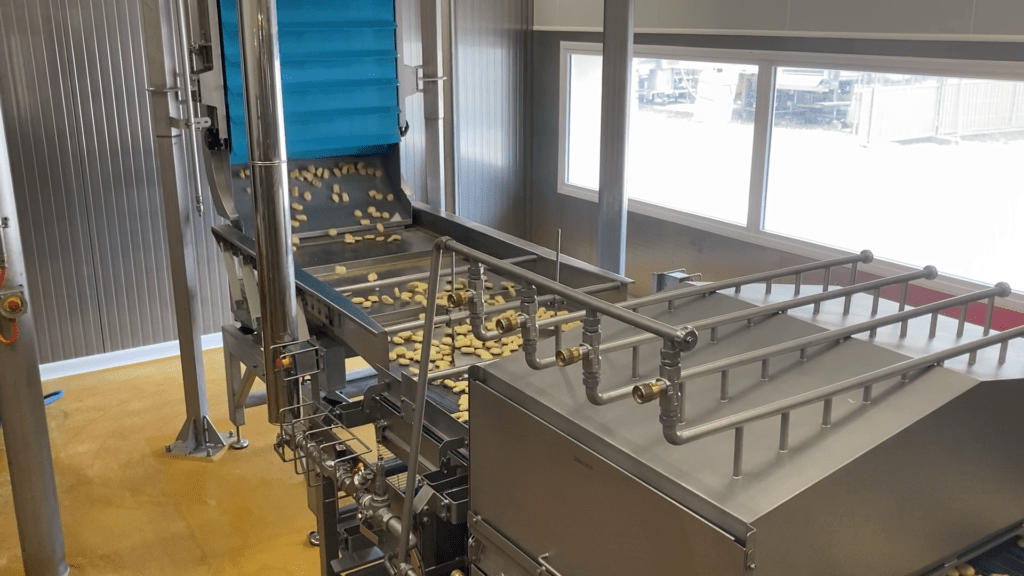

Fryer Loading

We design tailor-made stainless steel mesh conveyors to meet your specific needs for fryer infeed and outfeed.

Freezer Loading

We offer a range of solutions to optimize freezer infeed and outfeed. Our outfeed systems align your products as they leave the freezer.

Ensure optimal product transfer in and out of freezers or chillers with our low-wrap conveyors.

Coating

Protect your products from freezer burn and dehydration.

Our glazing solution enables you to continuously spray your breaded products at an adjustable rate with a liquid solution (water, preservative, etc.).

Detection of Non-Compliant Products

Contain foreign bodies with our foreign body detector, DPM or X-ray solutions.

Our solutions include checkweighers, ideal for eliminating products with weight errors.

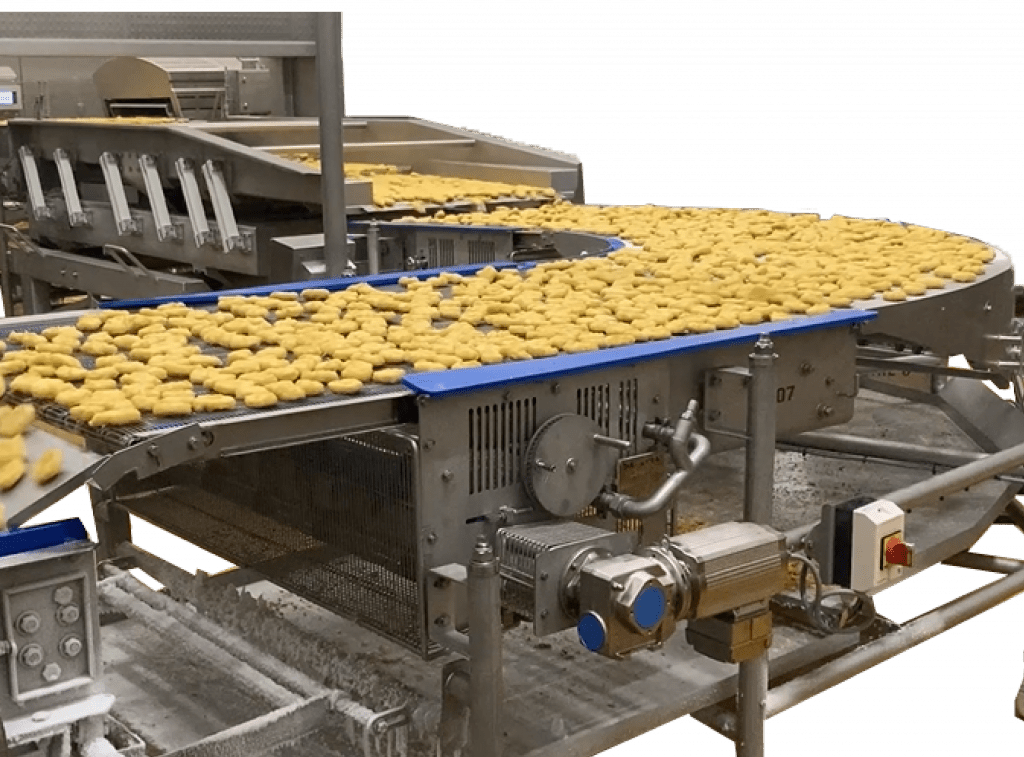

Vibrating Conveyor

Vibratory conveyors can be used to spread out products prior to discharge and/or to time the supply of multihead weighers.

Multihead Weigher Loading

Our multihead weigher infeed solution optimizes your packaging process.

Improve Your Machine Availability with Our Hygienic Design

As food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors, reducers, sensors…)

Hygienic Design+ finish:

Microblasting (ra : 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

Removal of belts and accessories without tools.

Storage cart available on request

ZERO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow tubings on all our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Improve your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That’s why all of our nugget lines are designed to minimize the risk of RSI and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing the production of superior quality nuggets. Our nugget lines are equipped with ergonomic features to help operators work comfortably and efficiently. To this end, we integrate custom height-adjustable equipment into our solutions to provide optimal height and working radius.

Optimize Production with a Customized Solution

At Acemia, we know that every company has specific production needs and objectives. That’s why we offer customized nugget solutions to optimize production in your plants.

Our experts will work closely with you to design a solution tailored to your needs and production objectives. We take into account all aspects of your production process, including food safety, productivity and quality. Acemia will custom design a solution based on the number of stations, your available space, your production rates and the size of your products, in order to provide you with a solution that meets your requirements.

With our customized solution, you will benefit from a more efficient, more profitable and higher quality nugget production. You can also reduce downtime and maintenance costs, while improving food safety and regulatory compliance.

Breaded Products Line

Breaded Products Line