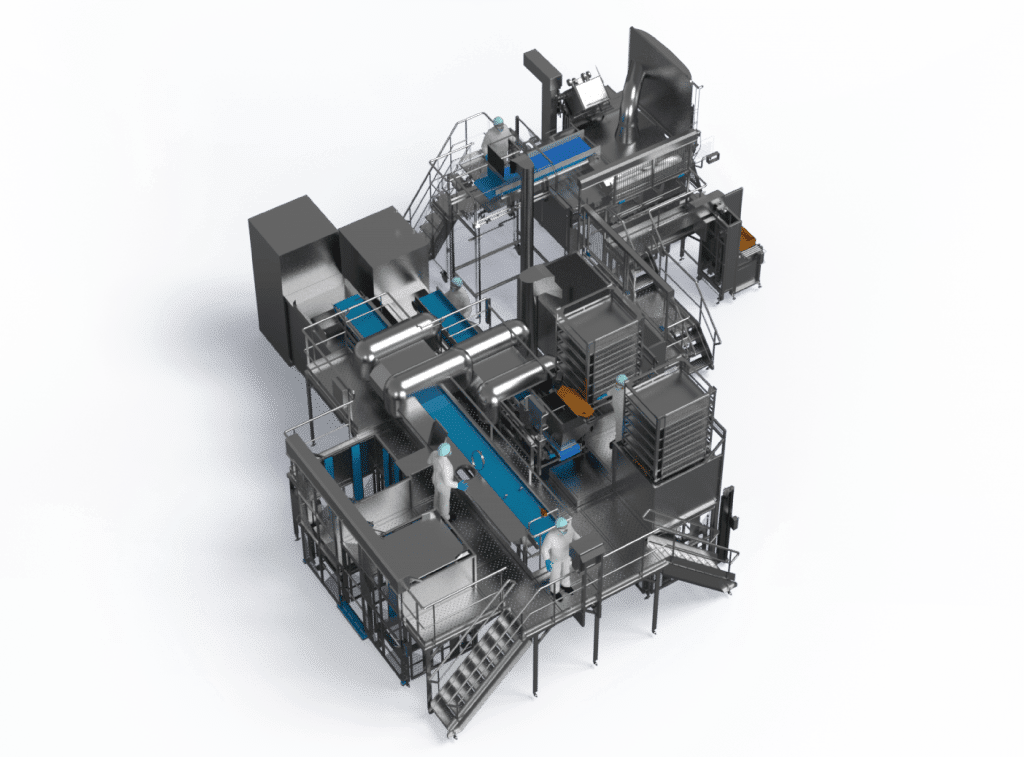

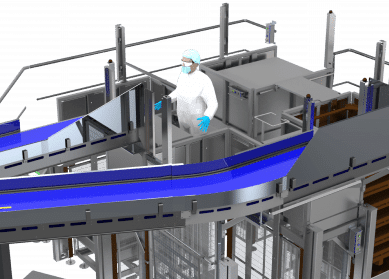

Unpacking Station

Our unpacking stations allow you to unpack your raw materials and food ingredients efficiently and safely. This step is particularly important to avoid any cross-contamination of food products and thus ensure the quality and safety of your products.

To optimize the unpacking of your raw materials and maximize your throughput, our experts design the unpacking station best suited to your needs (number of stations, available space, throughput, products, downstream process, etc.).

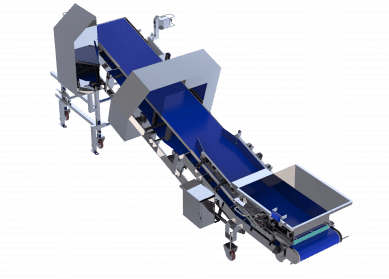

Improve Your OEE with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors,…)

- Hygienic Design+ finish: Microblasting (ra: 6.4)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

Removal of belts and accessories without tools.

Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

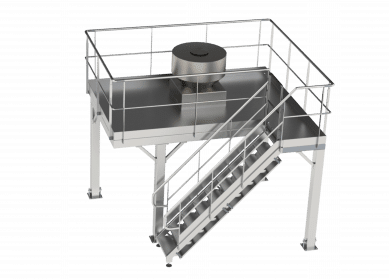

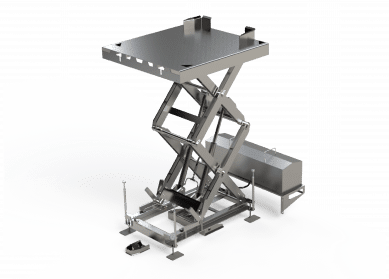

Improve You Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That’s why our unpacking stations are designed to minimize the risk of RSI and improve the safety of your operators. Our experts have developed a real expertise in designing state-of-the-art equipment to preserve the safety of your operators, while guaranteeing superior production. Our unpacking stations are equipped with ergonomic features that help your operators work comfortably and efficiently. To this end, we integrate custom height-adjustable equipment into our solutions to provide optimal height and working radius.

Optimize Your Production thanks to a Customized Solution

Our unpacking stations are designed to meet the specific needs of each company. They can be equipped with conveyors to move raw materials and food ingredients automatically and efficiently, or with lifting equipment to move heavier bags and boxes.

Yes, a raw material unpacking workstation can be optimized to improve production by using a customized solution. Indeed, each food company has specific needs and constraints in terms of space, raw materials, production process, equipment and personnel.

Acemia develops a customized unpacking station for the raw material unpacking workstation, taking into account these specificities to create an optimal working environment that improves productivity and production quality.

Our custom solution allows for better ergonomics to reduce worker fatigue and injuries, thus improving efficiency and productivity. We can integrate quality control systems such as metal detectors, ensuring compliance with current health and quality standards.

In short, with our custom-built unpacking station, production can be optimized to improve the quality, safety, efficiency and sustainability of the agri-food business.