The worldwide demand for ready meals continues to grow. Your customers’ requirements in terms of quantity, quality, and production diversity are increasingly significant. The multitude of ready meal recipes implies complexity in managing flow and cleaning between different recipes.

Ensuring food safety while maintaining productivity is one of your priorities. Therefore, the hygiene and cleanability of your lines are essential elements for delivering your orders and satisfying your customers.

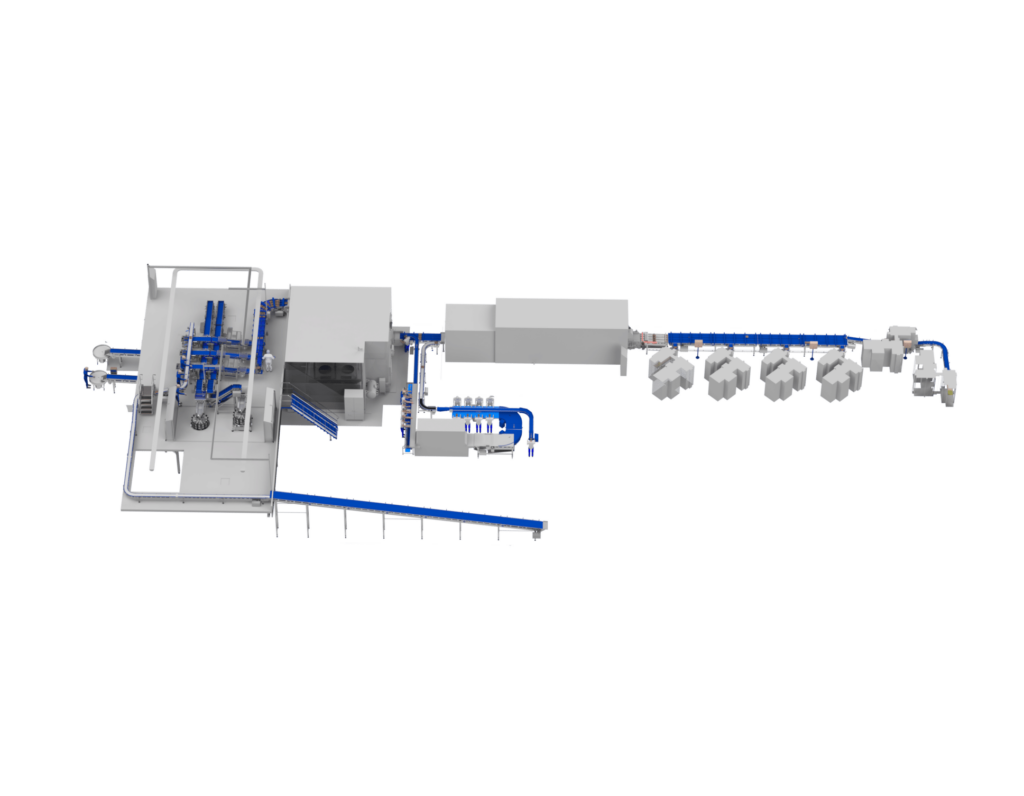

Acemia offers complete material handling solutions for ready meals. From the preparation of bare products to tray placement. We also design equipment for buffer accumulation management, thermoformer or flowpack feeders, and machines dedicated to packaging management.

Improve Your OEE with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors, reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

Removal of belts and accessories without tools

Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That’s why our solutions are designed to minimize the risk of MSDs and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing high-quality production. Our solutions are equipped with ergonomic features to help operators work comfortably and efficiently. To this end, we integrate custom height-adjustable equipment into our solutions to provide optimal height and working radius.

Forming Machine Output

To optimize the loading and unloading of your furnaces, our conveyors can perform :

- Vision control

- Re-trimming by mechanical shovel or AIMTM technology:

to ensure more homogeneous and densified filling - Ejection of non-compliant products to a manual reclaim

area

Oven Inlet/Outlet

Our equipment organises and optimises the loading and of your oven.

At the oven entrance, our conveyors are equipped with a system detection that sprays water onto the trays before baking. Protect your products from freezing and dehydration. Apply your aqueous solutions (water, colouring, preservatives oil, etc.) on your products to improve their appearance.

Ergonomic Workstation

A removable manual edge diverts the flow of trays towards a curved modular belt conveyor.

The trays are transported to picking stations. The bare products are removed from the trays manually and placed on a stainless steel mesh conveyor.

Empty trays are collected by picking operators picking operators, who form stacks that are passed on by an operator upstream and downstream of the toasting machine.

Fryer Feeder

An oiling tank with a pump to regulate the level of oil pump transfers the products to the input of the toasting machine. The grilled gyoza are transferred onto a positive drive PU belt conveyor where side-by-side operators fill the empty trays with the toasted gyoza.

The full trays are deposited on a modular belt conveyor which transfers the flow downstream where an operator the trays onto the freezer spiral.

Freezer Inlet/Outlet

At the freezer outlet, an ambient air blower is sprayed onto the products to limit the breakage of frozen the edges of products during transfers. At end of the conveyors, a plate turns the trays upside down

the trays upside down to transport them on PU belt conveyors.

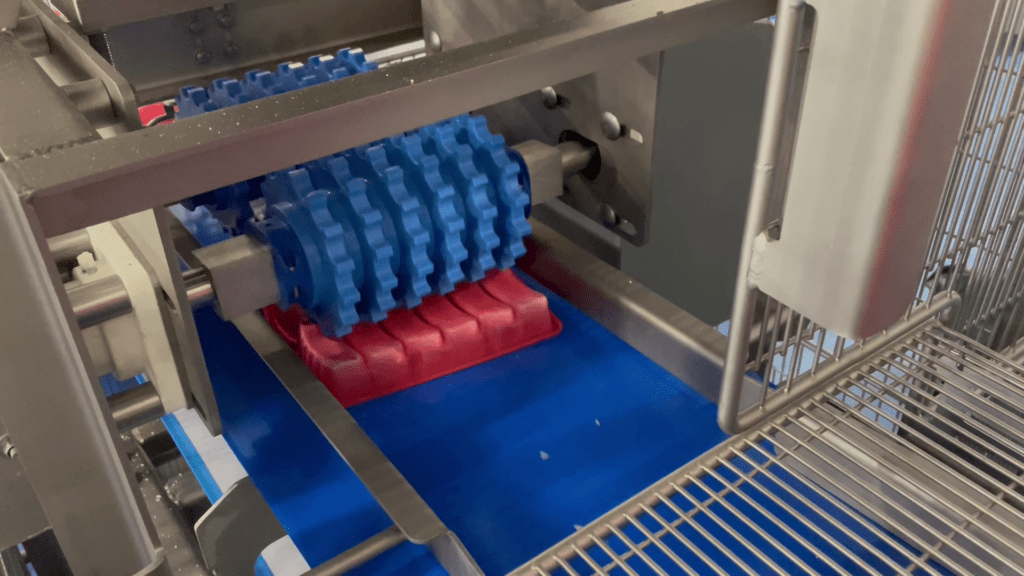

Demoulding Products

The trays are passed through a demoulding unit to release the frozen products.

The freed products fall into the free space between the downstream downstream PU belt conveyors.

The trays are picked up by operators at the front operators, who check that any products still stuck possibly stuck.

Multihead Weigher Feeder

The released products fall into chutes at the end of the conveyors the end of the conveyors to be transferred to an conveyor.

The products are then transferred to a vibrating hopper and a multihead weigher that doses quantities to a bagging machine.