Buffer

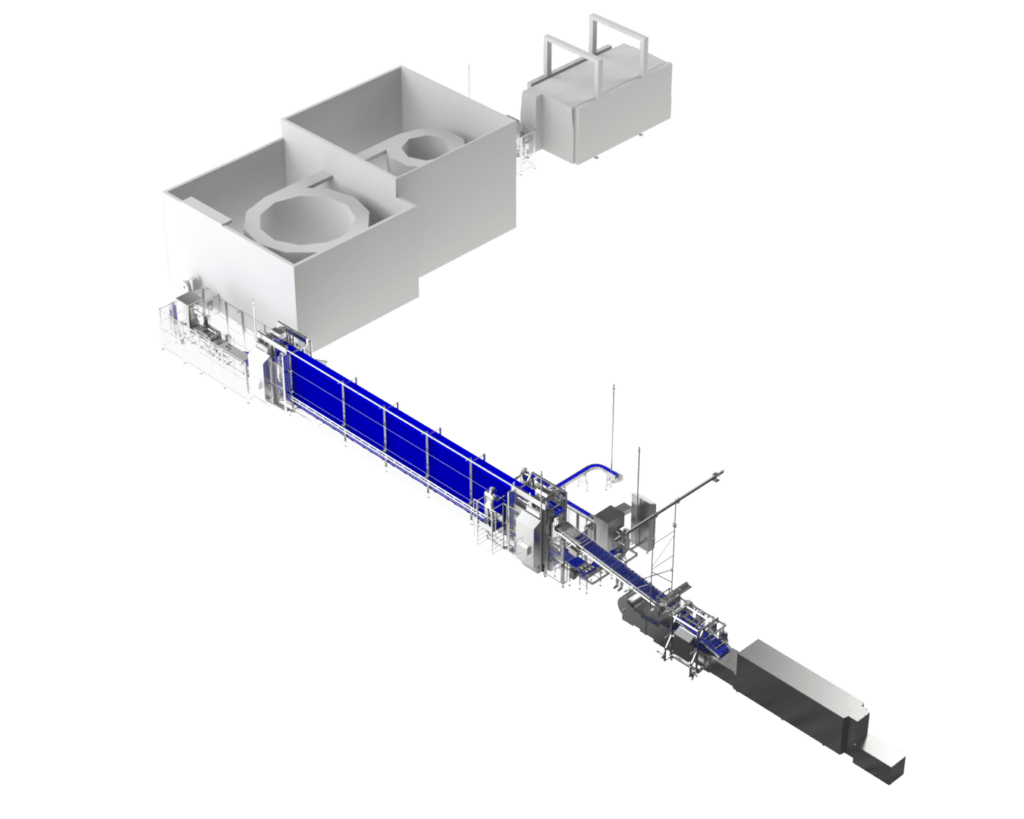

Acemia designs multi-level buffers, with a system of rising and falling movements that is managed by a series of optical cells to ensure correct alignment of transfer heights.

Once the lift conveyor has reached the selected level, the products are transferred step by step to a multi-level conveyor to optimise product cooling.

We have accumulation management solutions for all types of bare products, trays, cartons or packaged products.

Improve Your OEE with Our Hygienic Design

As a food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors,…)

- Hygienic Design+ finish: Microblasting (ra: 6.4)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools.

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Optimize Your Production with a Tailor-Made Solution

Guarantee optimum productivity and efficiency with our buffer solutions. Our solutions are designed to meet the specific needs of each company and offer you a customised solution for temporarily storing your products to optimise your production operations.

Storage capacity can be adjusted according to the size of your products and the number of buffer levels.

This solution allows you to respect (or not) the FIFO principle.

Our debuffer solution can handle different types of product (in trays or not).

Each of our solutions combines delicacy and efficiency to respect the integrity of your products and maximise your production. Our solutions adapt to the speed of your lines. We adapt our solutions to your constraints and requirements (number of stations, available space, speed, product sizes, etc.).

Our engineers and technicians work closely with you to understand your constraints, needs and production objectives. They then assess the working environment and existing equipment to design a customised solution that maximises the space available in the oven and reduces loading time.

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the health and safety of your employees is essential to creating high-quality products. That’s why all our lines are designed to minimise the risk of RSI and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing high-quality production. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To achieve this, we incorporate bespoke height-adjustable equipment into our solutions, offering optimum height and working radius.