Since March 2021, France has seen a significant increase in product recalls in the food industry. Faced with this reality, it is crucial to understand the reasons behind these recalls and identify solutions to minimize the risks to consumers.

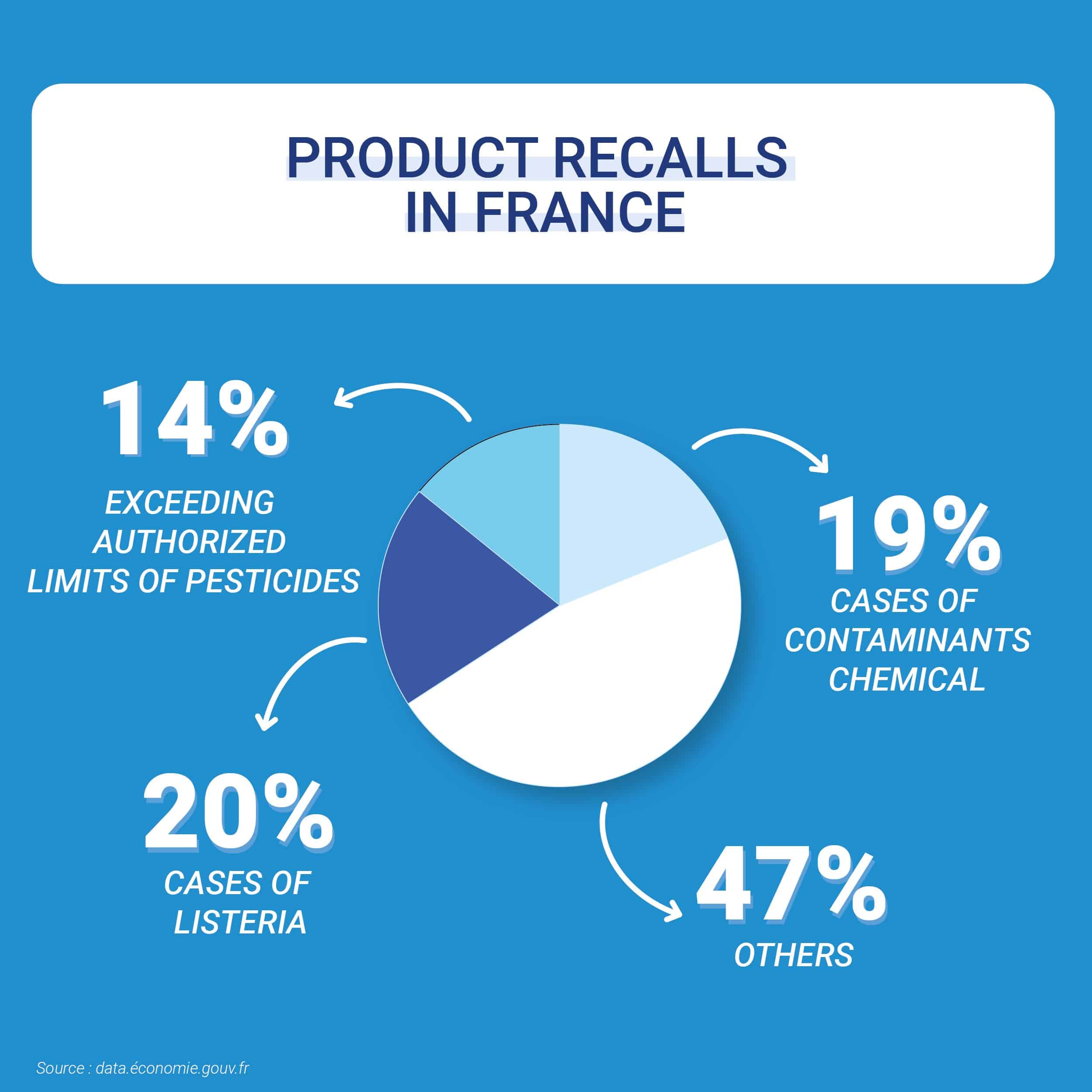

Food product recalls in France are mainly due to biological and chemical contaminants, with some revealing figures:

Certain types of product are more frequently recalled because of their vulnerability to contamination:

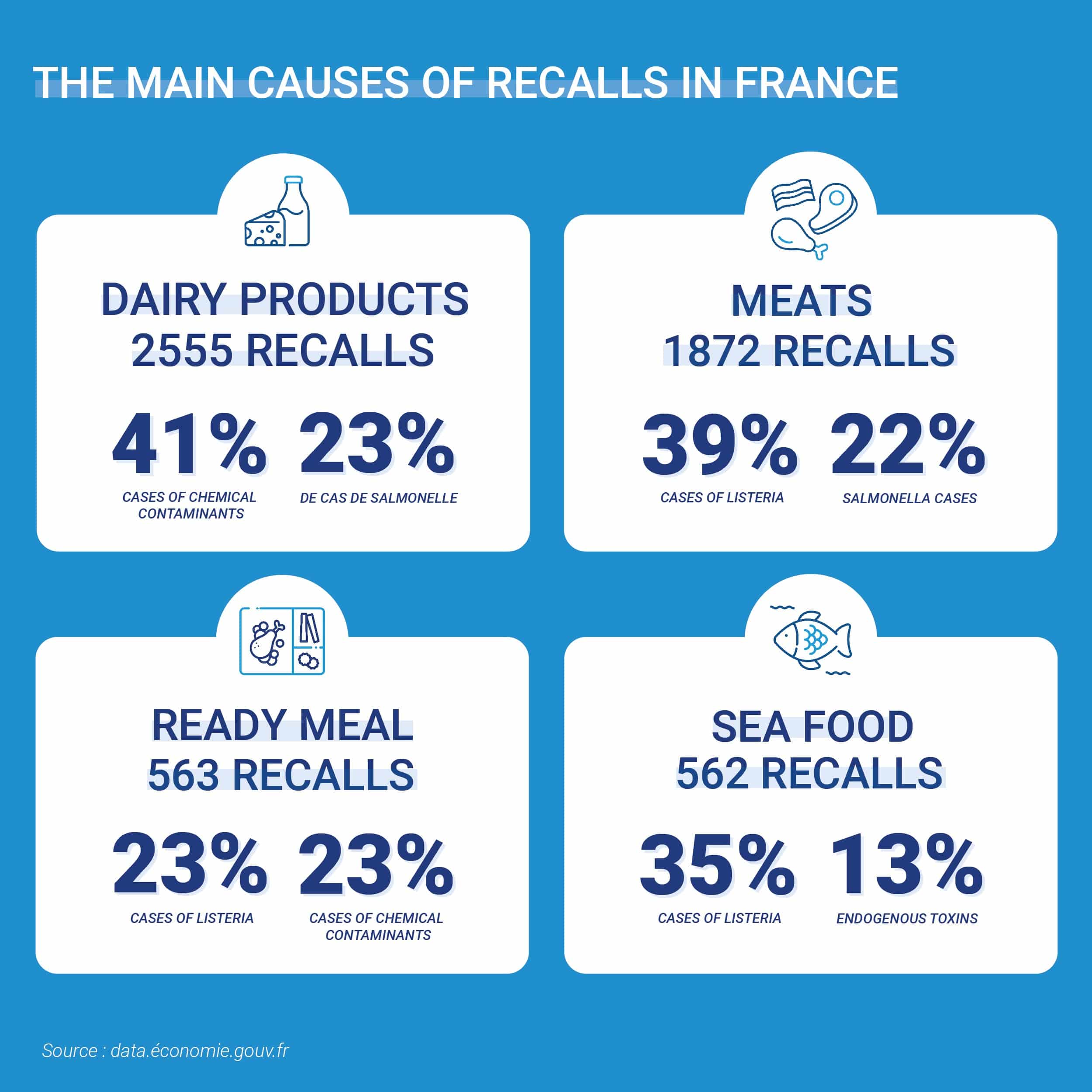

Meat and dairy products: This segment is particularly concerned by biological contamination with bacteria such as Salmonella and Listeria. In 2021, 2,555 recalls were recorded for meat and dairy products, representing a significant proportion of incidents.

Prepared dishes: With 1,872 recalls, prepared dishes account for a significant proportion of products affected, often due to the complexity of their production chains and the presence of multiple ingredients that may be contaminated.

Seafood products: Chemical contamination and endogenous toxins are responsible for 562 recalls. These products are particularly sensitive to poor handling and storage practices.

To limit recalls and guarantee food safety, rigorous measures must be adopted throughout the production chain:

Product recalls are a major challenge for the food industry and consumer safety. The figures demonstrate the importance of proactive measures to reduce these incidents. By adopting rigorous practices and raising awareness throughout the production chain, it is possible to protect consumers and restore confidence in food products.

Roméo CABRITA

romeo.cabrita@acemia.fr

+33 (0) 6 26 88 42 96

Pierre CALAS

pierre.calas@velecsystems.com

+33(0) 7 82 16 38 22