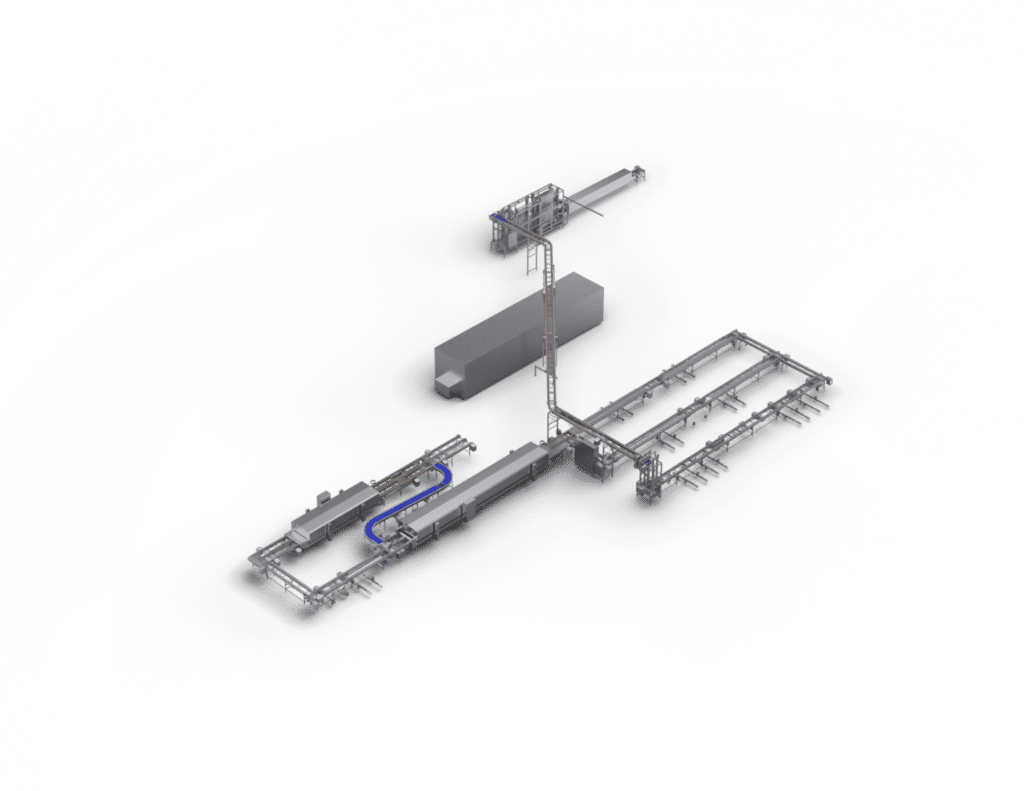

Producing spreads in large quantities while ensuring consistent quality is a challenge for your factory. Precise ingredient dosing, flow management, and packaging are key steps to ensure optimal yield.

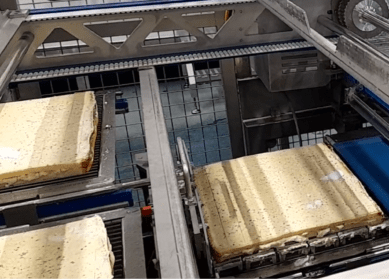

With to our dedicated canapes line, you control every stage of production: uniform spread application via stencil dosing system, molding to prevent overflow, and double freezing to preserve quality. The cutting into regular portions and adapted conveying maintain product integrity, while the automatic tray recirculation ensures a continuous flow.

Designed to meet industrial requirements, our equipment optimizes speeds while guaranteeing consistency and impeccable hygiene. Configurable to your needs, they integrate seamlessly into your existing environment.

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

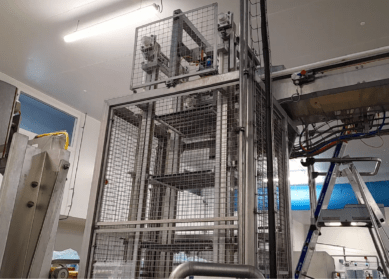

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That’s why all our ham lines are designed to minimize the risk of MSDs and improve the safety of our operators. Our experts have developed a real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing the production of high quality ham. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To this end, we integrate custom-made height-adjustable equipment into our solutions to provide optimal height and working radius.

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel 304L solution

IP69K

- Hygienic Design+ finish: Microblasting (0.8)

EASY TO CLEAN

Man-height equipment for easy access, monitoring and sanitation.

Automated cleaning with our Cleaning-in-Place system.

ZERO WATER RETENTION

Open, inclined structure to avoid retention zones.

No hollow bodies on any of our equipment.

WATER SAVING AND

HYGIENE

Down to 50% reduction in water and disinfection product consumption thanks to CIP.