In the food industry, handling fragile products is a constant challenge. Whether it’s delicate fruit and vegetables, seafood or dough-based products. Ensuring efficient transport while preserving product integrity is essential to guaranteeing food quality and safety.

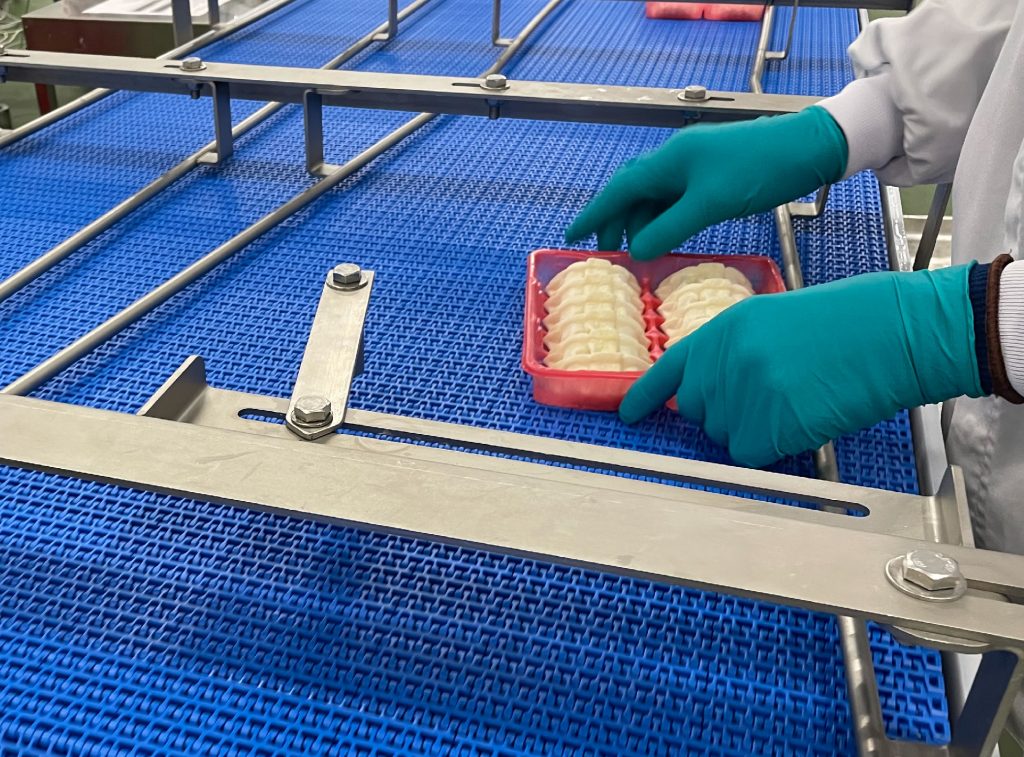

Food products such as biscuits, frozen goods, and fresh pasta products (gyoza, etc.) are often delicate and sensitive to shocks, compression, and vibrations. The slightest impact can lead to damage, deterioration of quality, or even product contamination. This makes the handling and conveying of these products particularly delicate and requires a carefully designed approach.

Handling fragile products presents several challenges. First, it is essential to minimize sudden movements and changes in direction to avoid damage. Additionally, implementing suitable conveying systems is crucial to ensure the proper transfer of products throughout the process.

In response to these challenges, the food industry is adopting innovative solutions for handling fragile products. Specially designed conveyors with soft surfaces, cushioning materials, and advanced control systems are used to minimize the risk of damage. Furthermore, technologies such as picking robots enable precise and delicate handling of fragile products, reducing losses and waste.

In a sector where quality and food safety are paramount, handling fragile products takes on particular importance. By ensuring smooth transport and careful handling of products, food companies can guarantee customer satisfaction and maintain their reputation as trusted suppliers.

Hygienic design is essential in handling fragile products in the food industry. It aims to prevent contamination and facilitate equipment cleaning, thereby ensuring food safety and product quality. Equipment should have smooth, crack-free surfaces and be made from corrosion-resistant materials like stainless steel. By integrating these principles, companies reduce the risk of contamination, comply with regulations, and enhance operational efficiency, ensuring high-quality products for consumers.

Handling fragile products in the food industry represents a complex but essential challenge. By adopting innovative solutions and emphasizing quality and food safety, companies can overcome these challenges and ensure the success of their conveying operations.