In the food industry, product diversity continues to grow: in 2014, 18,958 new products were launched on the European market. To meet this demand, many production sites change formats, recipes, or packaging several times a day. Yet, production lines — and in particular conveying and automation — are not always designed to handle this variability.

At Acemia, we often see lines that appear efficient on paper but lose effectiveness in practice, simply because their architecture doesn’t allow for smooth transitions between product formats. These frequent changes directly impact productivity, material losses, and operator workload. In this context, it is essential to think of the line as an integrated system: conveying and automation make it possible to absorb changes without losing throughput.

As manufacturers are required to produce more references on the same equipment, line flexibility becomes a central issue. Changing formats often requires adjustments to guides, belt widths, transfer heights, or synchronization settings. These operations take time, consume resources, and sometimes result in errors or waste.

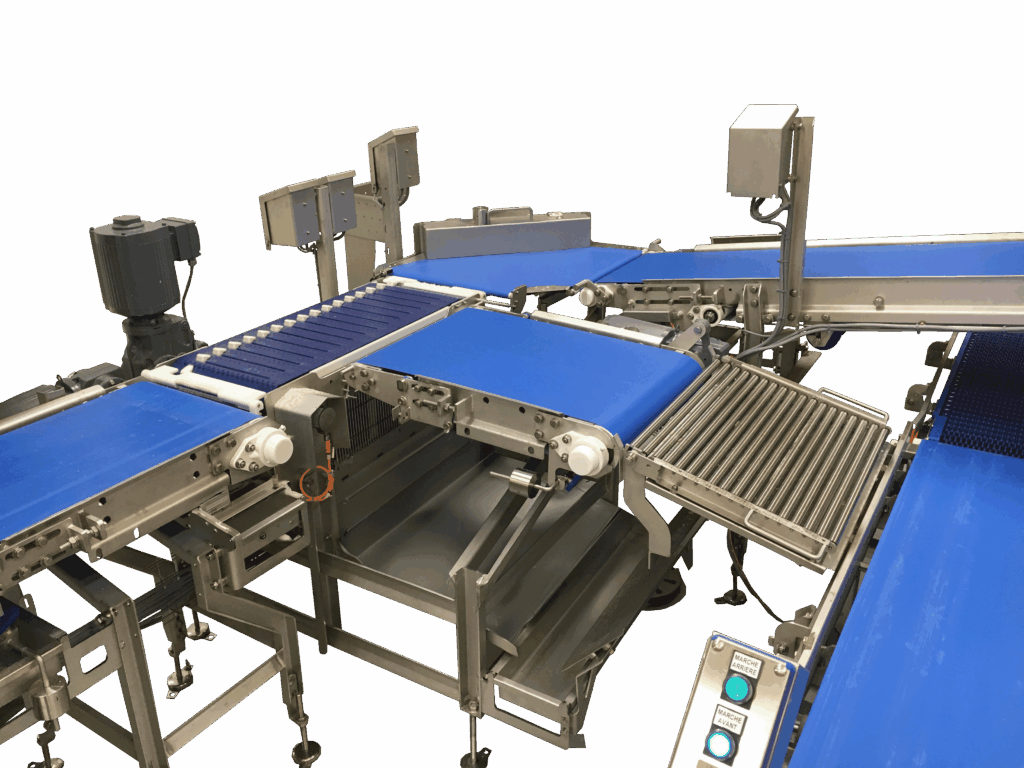

An ill-suited conveying system can slow down the entire process, even when the dosing, packaging, or weighing equipment is highly efficient. It becomes a limiting factor or even a bottleneck in flow organization. Conversely, automated solutions for sorting, distribution, or handling can ease transitions and secure the most sensitive steps. These systems integrate naturally into the line and enhance its agility.

Product variability imposes concrete constraints on conveying systems. When formats, weights, or packaging types change several times a day, the line must keep up — without causing excessive stoppages or product waste.

Several technical elements can address this effectively:

All of these solutions aim to maintain throughput despite product changes, while preserving product quality and operator comfort.

At Acemia, we integrate this flexibility requirement from the early design phase. The goal: to provide a line that can evolve with production needs, without requiring constant reconfiguration or repeated investment.

We work based on actual throughput, product formats, and cleaning constraints to design solutions that can handle variability while maintaining a high level of performance. And when product nature or process requirements call for it, we incorporate robotic solutions such as our RAID system (Robot Additional Ingredient Dispenser), which automates ingredient dispensing with precision and without interruption — even when recipes change frequently.

A well-designed conveying system is not just a technical solution. Combined with automation, it becomes an industrial agility tool that enables producers to quickly adapt to market changes while ensuring consistent flow.

Format changes are now part of everyday production. But your line still needs to keep up. At Acemia, we design conveying systems that adapt to the realities of food production workshops: throughput, footprint, hygiene, ergonomics — nothing is left to chance.

How about your line? Is it ready to keep pace?

Contact us to discuss your project or to explore possible improvement opportunities together.