In the food processing industry, every gram counts. Reducing material loss in production is not just a matter of profitability: it is also a requirement for sustainability, hygiene, and competitiveness. At Acemia, we are convinced that intelligent conveying solutions play a central role in this approach. Here’s how conveying can become a concrete lever to limit losses and improve industrial performance.

Material losses can occur at various stages of the industrial process: during transfer, sorting, dosing, or packaging. These losses, sometimes invisible to the naked eye, have a significant impact:

A well-designed conveying system is not just a simple transport method between two machines. It is a strategic link in the production chain. Properly designed, it enables to:

To meet the demands of efficiency and loss control, Acemia designs tailor-made conveying and transit solutions adapted to the specific constraints of each production site. From the study phase, our teams identify critical points likely to generate material loss, whether it concerns the characteristics of transported products, targeted production rates, or interactions with existing equipment. Based on this, we design lines incorporating concrete devices to guarantee optimal yield.

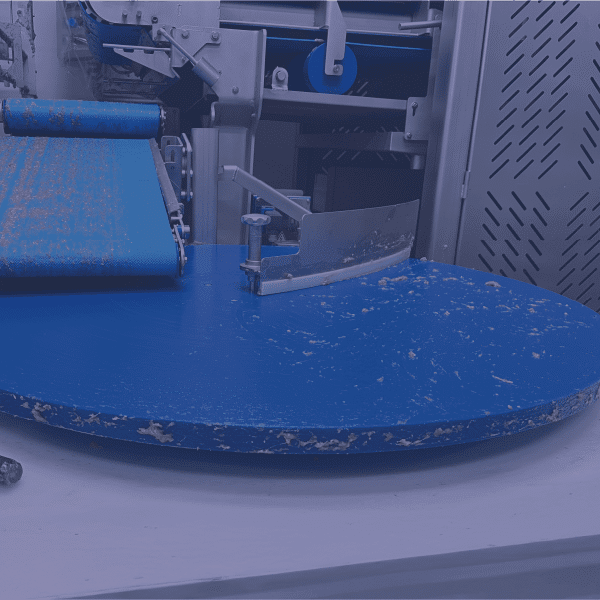

Our conveyors are designed to limit material loss by maintaining product integrity throughout transport. We select modular plastic belts and stainless steel conveyors that ensure delicate and effective handling. Depending on specific needs, we adjust positive drive belts and custom guiding elements to ensure a continuous flow without loss or product alteration.

Thanks to these technical solutions adapted to each client’s specificities, Acemia helps its partners improve their overall yield while reducing material loss.

Reducing material loss in production is not an option: it is a necessity to remain competitive, responsible, and efficient. By placing conveying at the heart of this strategy, manufacturers can significantly improve their overall yield. At Acemia, we put our expertise at the service of these goals, with solutions designed to last, evolve, and adapt to your real-world conditions.

Do you have a project or want to improve your existing setup? Our team of engineers is at your disposal to help you optimize your production.