The food industry plays a crucial role in feeding the world’s population, but it relies heavily on the hard work and efficiency of its operators. They play a vital role in the production, processing and distribution of the food we eat every day. So it’s vital to improve their working conditions, to guarantee both their well-being and the quality of their products. Here are a few key steps.

Worker safety is the cornerstone of a healthy working environment. Make sure your operators have access to adequate personal protective equipment (PPE), safety training and clear emergency procedures. Encourage incident reporting and safety problem solving to prevent accidents.

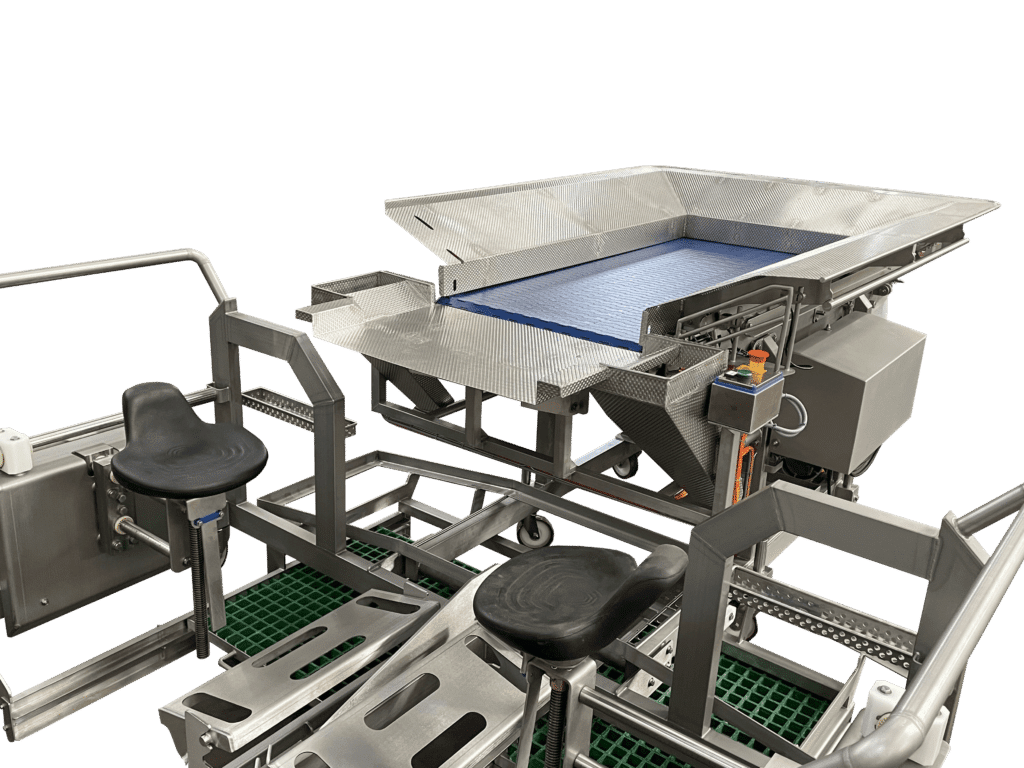

Repetitive and physically demanding tasks are commonplace in the food industry. To improve working conditions, invest in ergonomic workstations, modern equipment and adapted tools. Reducing physical fatigue and musculoskeletal disorders (MSDs) contributes to employee satisfaction.

Technology can considerably improve working conditions in the food industry. Automating dangerous or repetitive tasks reduces stress on operators. What’s more, computerized management systems can simplify data tracking and management processes, reducing the administrative workload.

Simplifying the use of equipment can considerably improve operators’ daily lives in a number of ways:

Don’t treat improving working conditions as a one-off task. Follow up regularly to assess the effectiveness of your initiatives and to take into account the changing needs of your operators.

By adopting all these good practices, companies can not only improve the satisfaction and well-being of their employees, but also increase their efficiency and productivity, which in turn contributes to better performance.

Would you like to improve your operators’ working conditions with ergonomically adapted workstations? Our team of experts is ready to help. Contact them for more information.