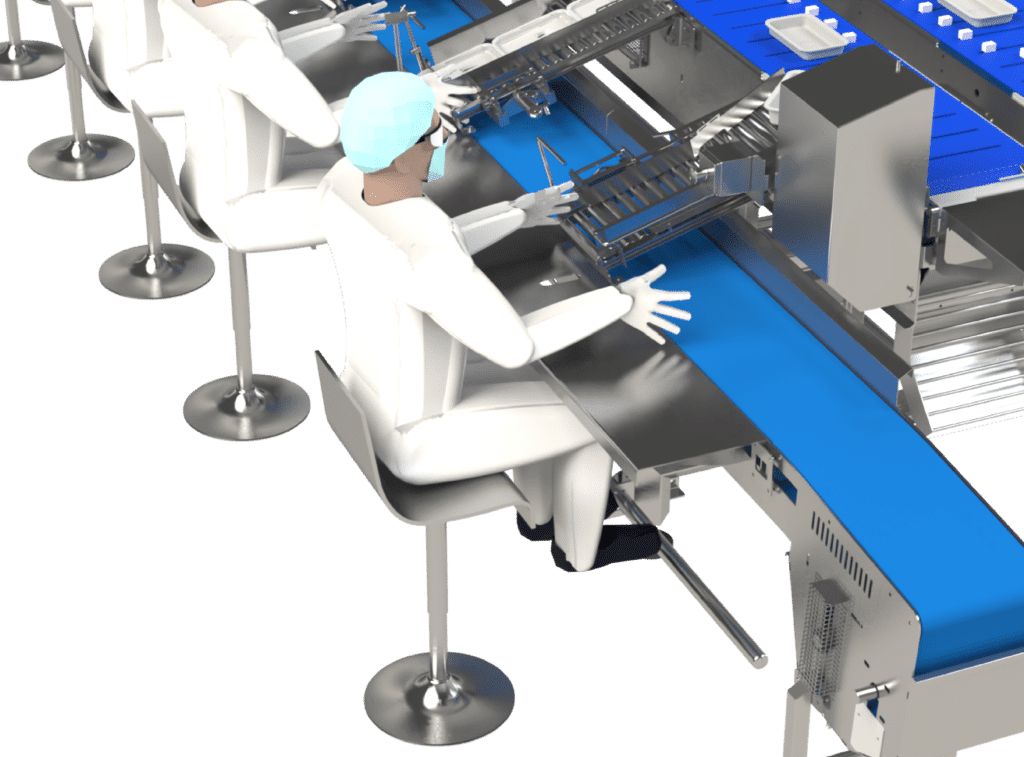

Ergonomic Workstation

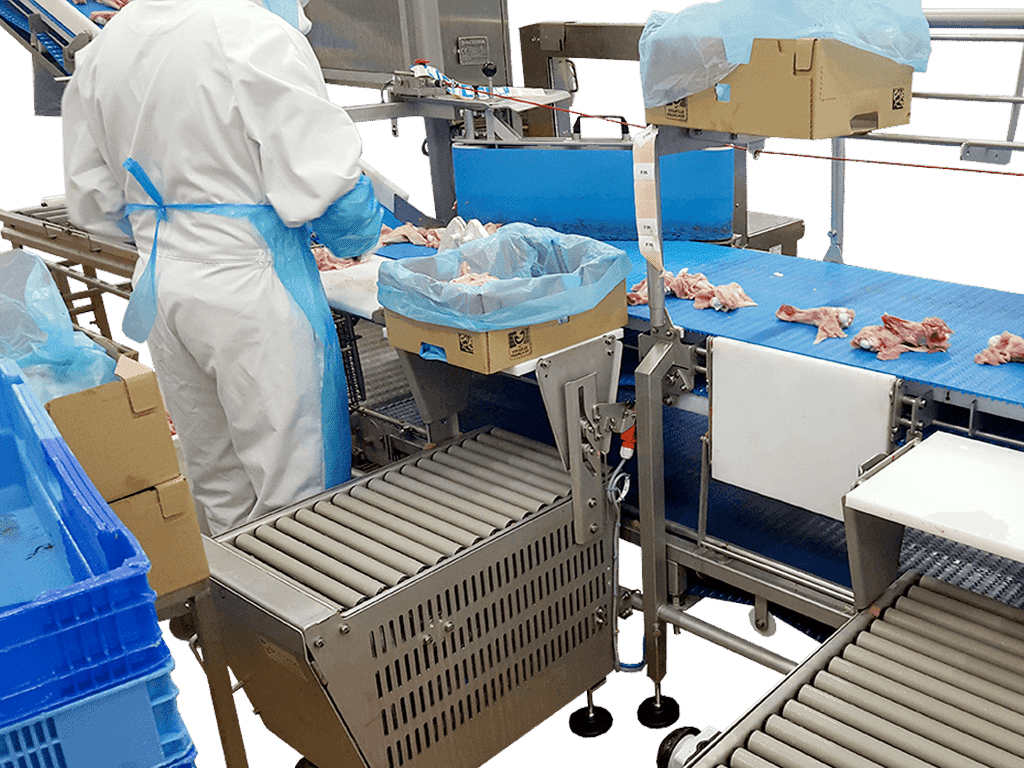

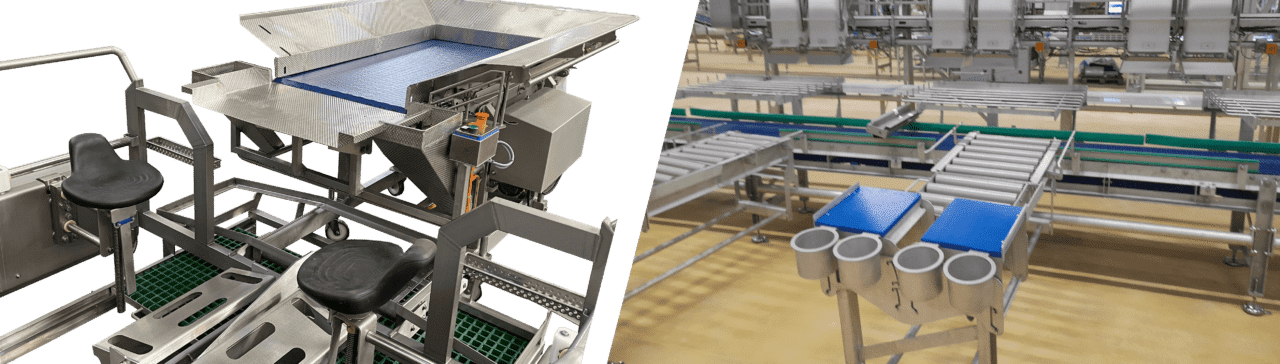

At Acemia, workstation layouts are studied on a case-by-case basis. We adapt our solutions to the environment, the available space, the required work rates and the formats used. Acemia integrates the best ergonomic recommendations in the design of workstations. Leveling systems and height-adjustable work benches can be designed.

We provide workstations with easily adjustable gratings to take into account the height of the operators. The workstation can incorporate removable shelves to facilitate the operator’s work. We integrate inclined workstations oriented towards the operator. Moreover, the ease of cleaning the machines as well as the safety of the operator are perfectly integrated in our thinking.

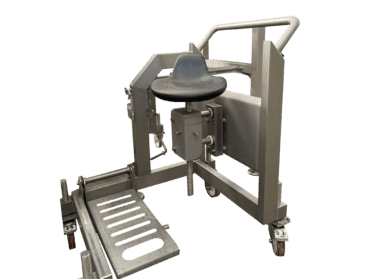

We integrate computer, weighing and labeling stations, as well as bin or pallet leveling. We can also equip the stations with standing seats to relieve the back.

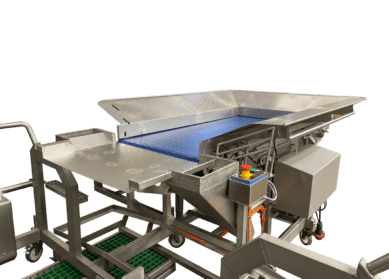

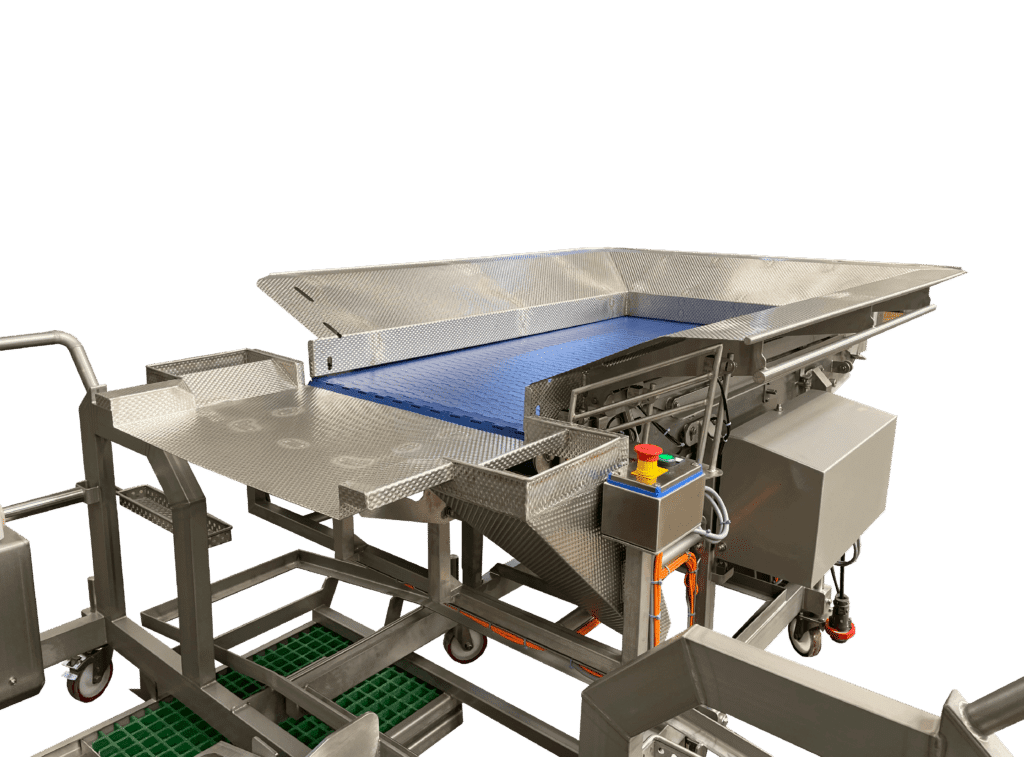

Unpacking Station

The unpacking station optimizes production efficiency by quickly preparing raw materials while allowing for an initial quality check. It helps reduce the risk of contamination, facilitates packaging waste management, and improves operator ergonomics — contributing to a safer and more productive working environment. In addition, it complies with all current hygiene standards, ensuring your processes remain fully compliant.

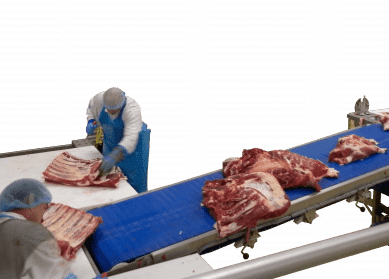

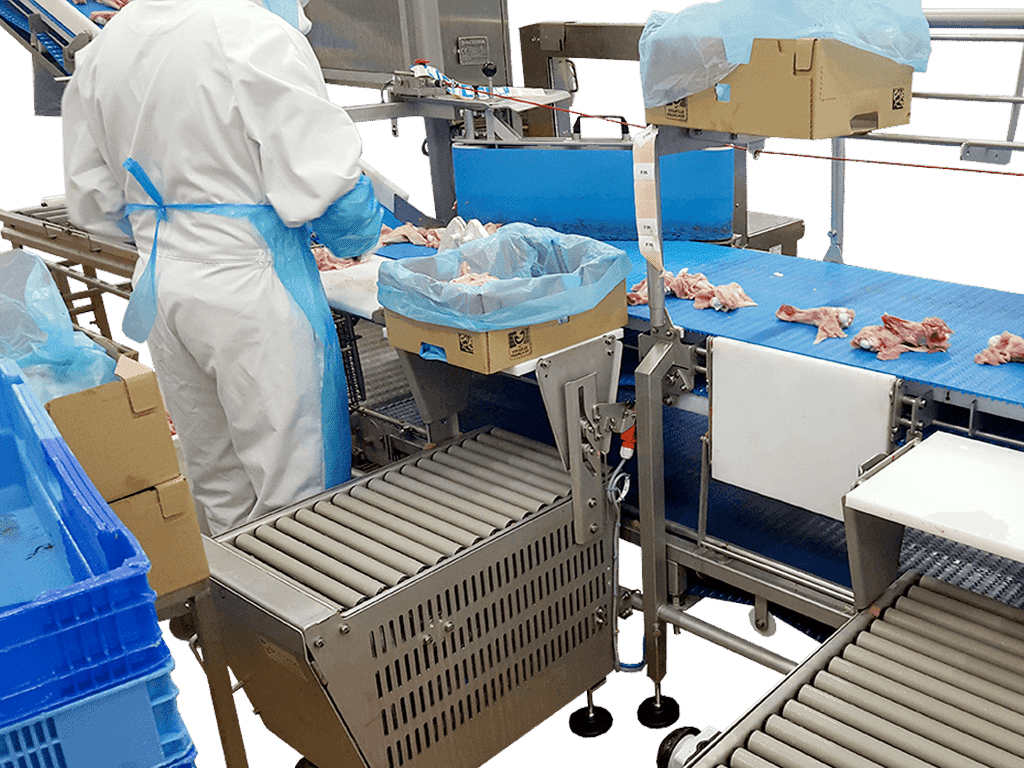

Poultry Preparation Station

The poultry preparation station optimizes production by reducing processing time and labor costs, thereby improving productivity. It ensures compliance with hygiene standards, minimizes waste, and provides rigorous quality control, strengthening food safety. This station also offers great flexibility, allowing production to be adapted to market demands, while maximizing the use of poultry by-products to reduce waste and increase profitability.

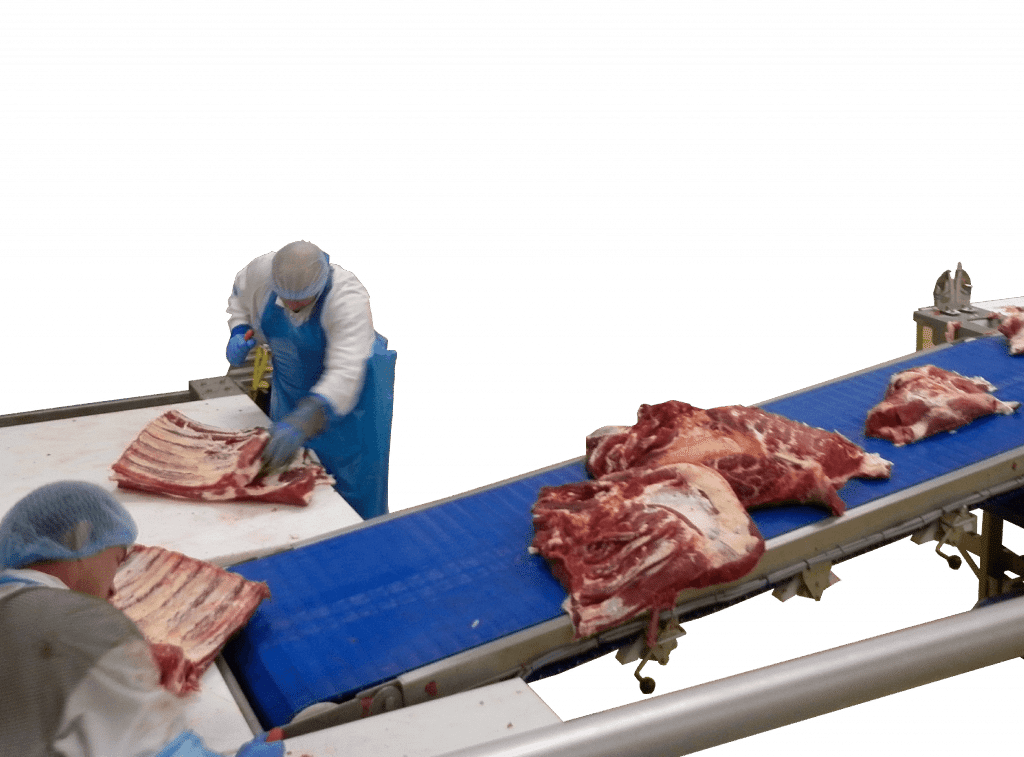

Deboning Station

The deboning station optimizes productivity by quickly removing bones, thereby reducing costs and accelerating the process. It improves the quality of the finished product with uniform, tender cuts while minimizing waste. Bones can be repurposed for other uses, allowing for better utilization of raw materials and reducing waste. The station also ensures compliance with hygiene standards and offers flexibility to adapt to market demands.

Clamping Station

The clamping station ensures precise alignment of products and keeps them in place, guaranteeing consistent quality and reducing errors. Flexible and modular, it adapts to different types of products, optimizes productivity by minimizing downtime, and enhances food safety by limiting contamination risks. It also reduces losses and waste, contributing to better profitability.

Tray Loading Station

The tray loading station optimizes production organization, ensures smooth product flow management, and adheres to strict hygiene standards. This station also offers flexibility to accommodate different products and packaging formats, while protecting the products from contamination. It accelerates packaging, thereby increasing productivity by handling more products in less time. Finally, it enhances the efficiency of other production stages by facilitating work organization.

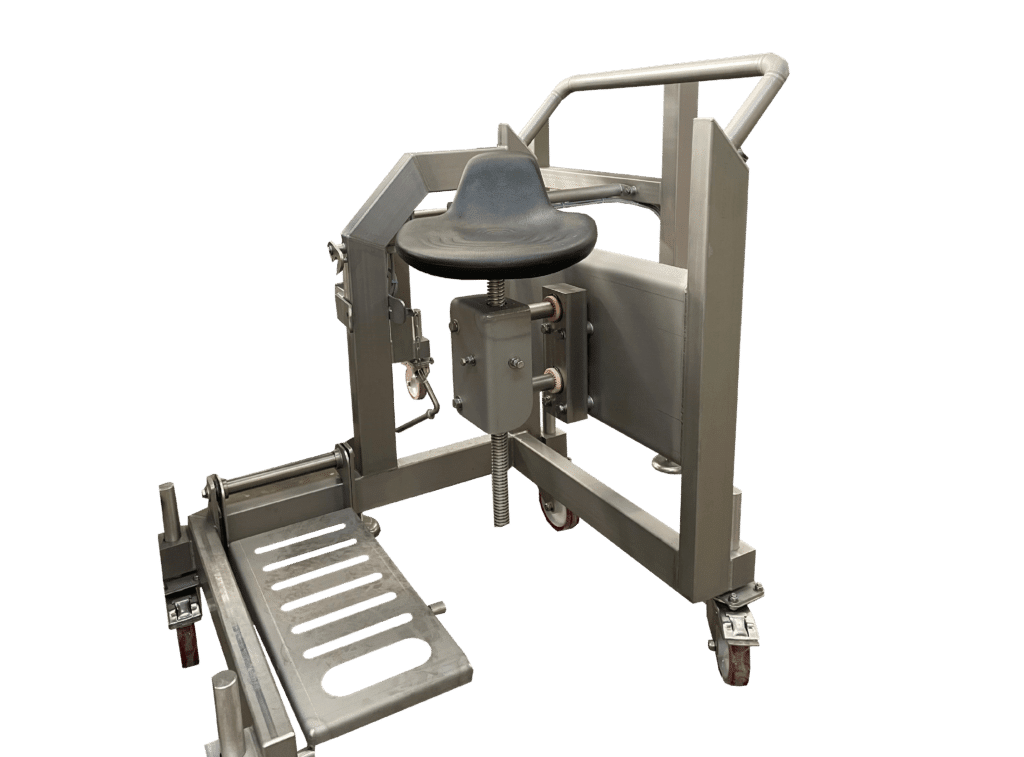

Height Adjustment Station – Standing

The standing height station improves ergonomics, reduces fatigue and musculoskeletal discomfort by promoting a more natural posture. It encourages smoother movements, increases productivity, and lowers the risk of accidents. The station’s adjustability enhances access to equipment and allows for alternating between standing and sitting positions. This type of station also optimizes workspace and contributes to employee well-being.

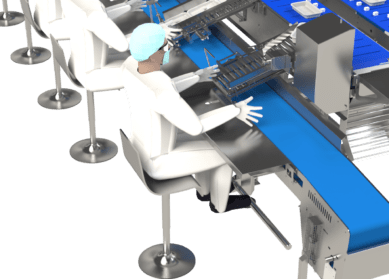

Height Adjustment Station – Seated

The seated height station enhances comfort, reduces fatigue and the risk of muscle pain, boosting productivity. It promotes a stable and ergonomic posture, minimizing the risk of injuries. By reducing interruptions caused by discomfort, it improves focus and work quality, while making the work environment more attractive and encouraging employee retention.

Icebreaking Station

The icebreaking station helps maintain refrigeration equipment in good condition, preventing breakdowns and production stoppages. It reduces energy consumption by optimizing machine performance. This station also contributes to a safer work environment by eliminating the slip hazards associated with ice buildup.

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That is why all our lines are designed to minimize the risk of MSDs and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing superior production quality. Our lines are equipped with ergonomic features to help operators work comfortably.