Bin Destacking and Handling

Optimize your production operations, ensure hygiene and improve productivity with our bin handling solution.

Our solution covers all stages, from initial handling to cleaning and reuse of bins. The bin turner simplifies bin inversion, the bin depiler automates unstacking, and the bin washer ensures thorough cleaning. Additionally, our bin management system for input and output to the washer optimizes loading and unloading for maximum efficiency.

By choosing our solutions, you benefit from better operational efficiency, enhanced safety for your employees, high hygiene standards, and time and resource savings.

Our solution is also flexible and adaptable, fully customizable to meet your specific needs, whether in terms of bin size, system configuration, or required features.

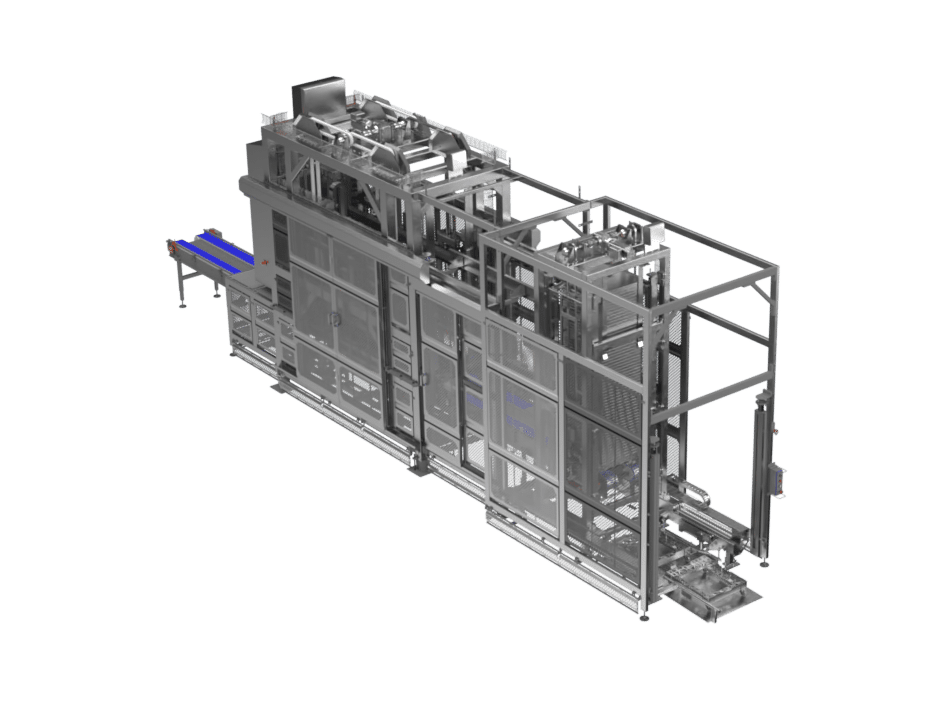

Bin Washer

Our washer infeed and outfeed bin management system is designed to optimize workflow and ensure maximum efficiency in your cleaning process. This automated system facilitates the loading and unloading of bins, reducing waiting times and improving productivity.

Bin Destacker

Our bin destacker is designed to automate and simplify the unstacking process, making your production run more smoothly and efficiently. This sturdy, easy-to-use unit quickly and safely separates stacked bins, optimizing your workflow.

Bin Tilter

Our automated bin turner is the ideal tool for simplifying and securing bin turning in your production process. Designed to be robust and easy to use, it enables effortless handling, reducing the risk of injury and improving the efficiency of your operations.

Improve Your OEE with Our Hygienic Design

As a food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).