Baking Tray Flipping

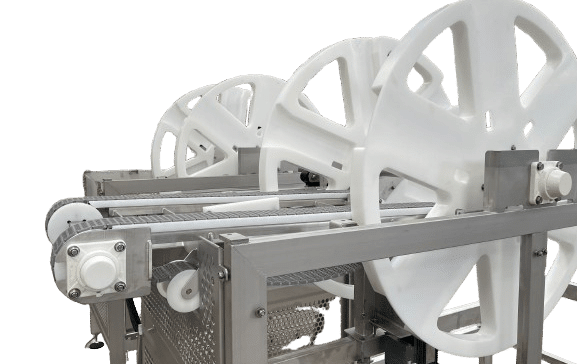

Baking tray flipping is a key step in the production of delicate products such as bread and pastries. When performed manually, this operation can pose risks to your teams and impact product quality.

Acemia offers custom automated baking tray flipping solutions tailored to your needs. Our systems ensure gentle flipping, preserving the integrity of your products while optimizing safety within your facilities.

With our solutions, flipping is performed continuously and precisely, reducing downtime and maximizing the efficiency of your production.

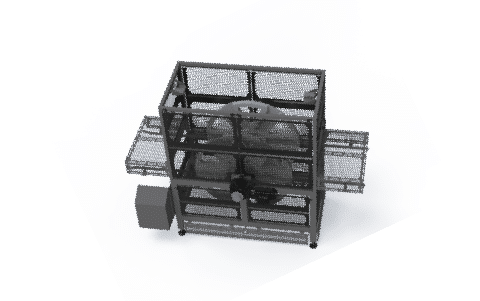

Improve Your OEE with Our Hygienic Design

As a food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

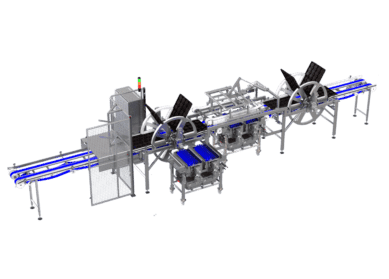

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the health and safety of your employees is essential to creating high-quality products. That’s why all our lines are designed to minimise the risk of RSI and improve the safety of our operators. Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing high-quality production. Our lines are equipped with ergonomic features to help operators work comfortably and efficiently. To achieve this, we incorporate bespoke height-adjustable equipment into our solutions, offering optimum height and working radius.

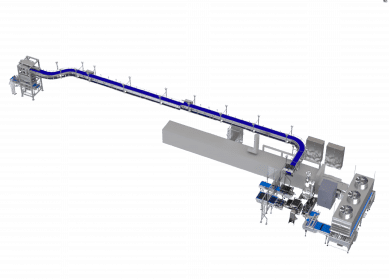

Maximize Your Production with a Flexible and Customized Solution

The bakery industry requires increasing flexibility to meet consumer needs, both in terms of production time and product range.

Now more than ever, you are striving to improve your OEE and reduce your risk of RSI. You need a continuous operation line with limited downtime: a real challenge for your delicate products (bread, buns, pastries…)! Their composition requires meticulous and ingenious applications capable of meeting your requirements for speed and product integrity.