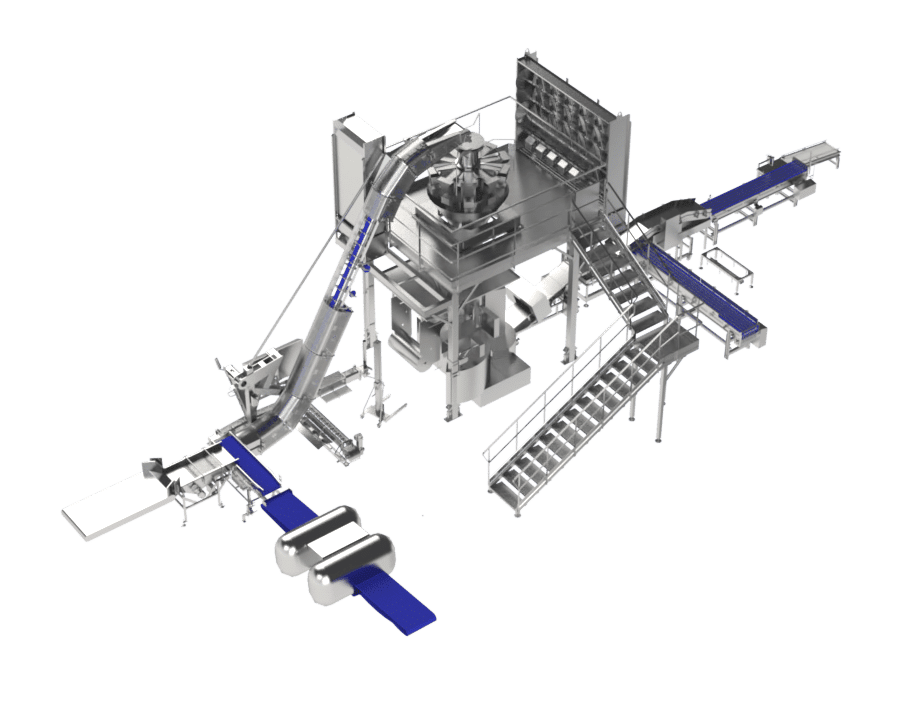

Vertical Bagger Loading

At Acemia, we engineer tailored bagging solutions to meet your production requirements. The equipment we provide handles your products with precision—whether dry, fresh, or frozen—and integrates seamlessly into your existing line.

Featuring smart automation, our systems optimize throughput while reducing operational workload. Precise dosing, secure sealing, and modular design make this technology a productivity booster—with no compromise on hygiene or reliability.

Streamline your process with future-ready packaging technology.

Improve Your OEE with Our Hygienic Design

As a food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Optimize Your Production with a Customized Solution

Ensure optimum productivity and efficiency with our multihead weigher infeed solutions. Our solutions are designed to meet the specific needs of each company, providing you with a customized multihead weigher infeed solution to optimize your production operations.

Each of our solutions combines sensitivity and efficiency to respect the integrity of your products and maximize your production. Our multihead weigher infeed solutions adapt to the speed of your lines. We adapt our solutions to your needs and constraints (number of stations, available space, speed, raw or frozen products, product sizes, etc.).

Our engineers work closely with you to understand your constraints, needs and production objectives. They then assess the working environment and existing equipment to design a customized tray packing solution that maximizes available oven space and reduces loading time.