Loading Solutions

At Acemia, we offer high-performance loading solutions, custom-designed to meet your specific needs. Thanks to our robust and modular equipment, we meet the strict requirements of food safety, hygiene, and productivity at every stage of your production processes. Our loading solutions are designed to optimize efficiency, reduce costs, and ensure maximum flexibility, delivering sustainable results.

We operate across various sectors, providing tailored solutions for loading barrels, ovens, freezers, and much more. Each solution is developed to improve the flow of your processes while ensuring product safety and quality throughout the entire production chain.

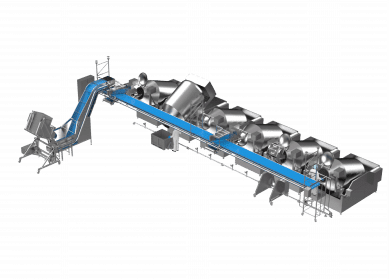

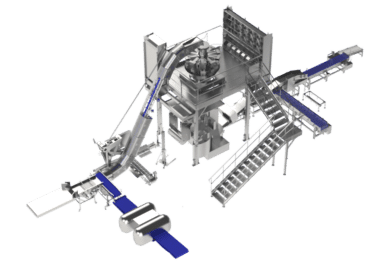

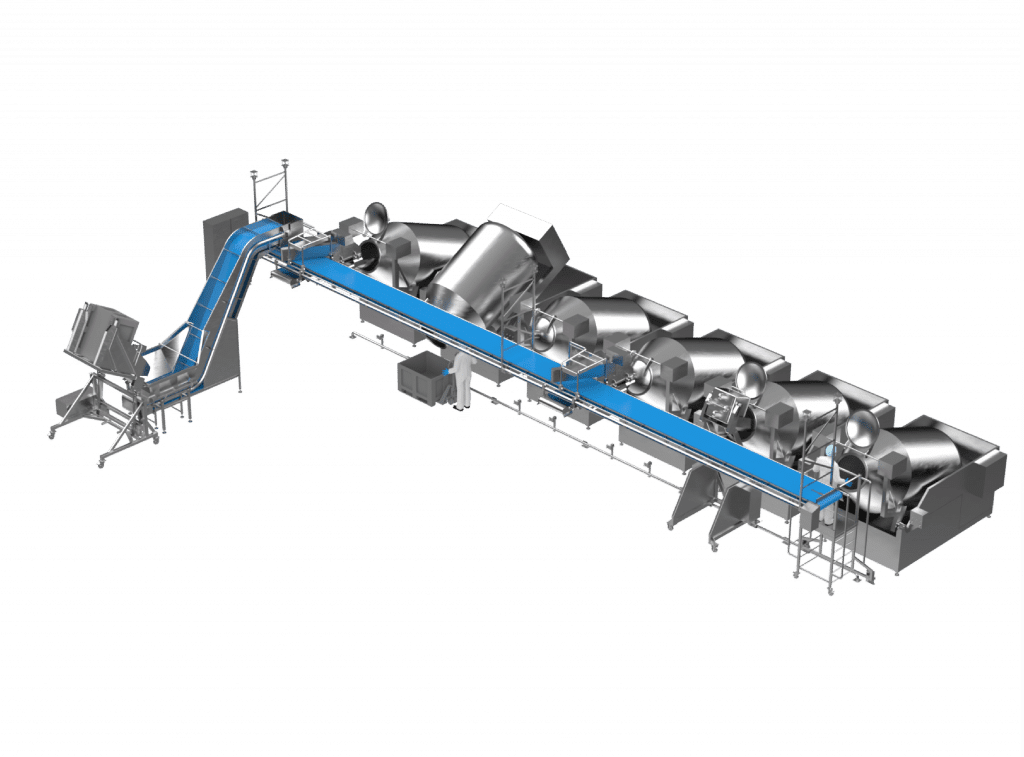

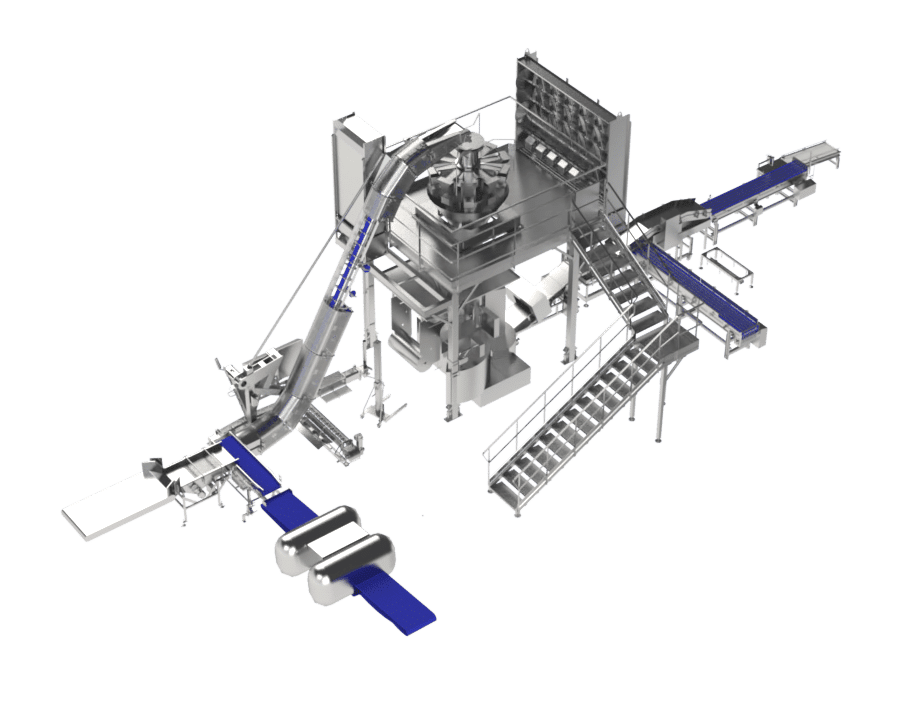

Mixer & Churns Loading

Churn loading enables efficient mixing of raw materials and finished products in the food processing industry. Designed to optimize production rates, our solutions are tailored to your specific needs—whether in terms of workstation count, available space, or product types. Easy to integrate into your production lines, they guarantee both maximum hygiene and enhanced efficiency, while reducing errors and improving productivity.

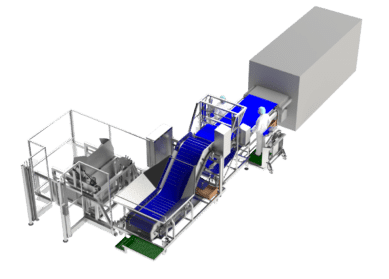

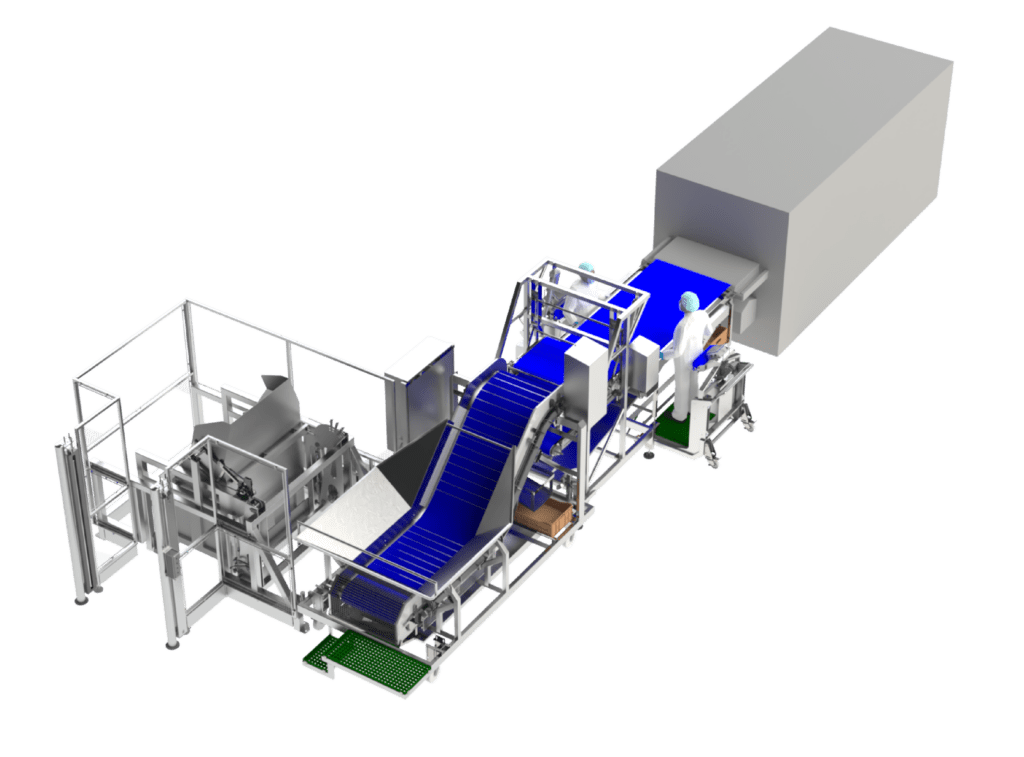

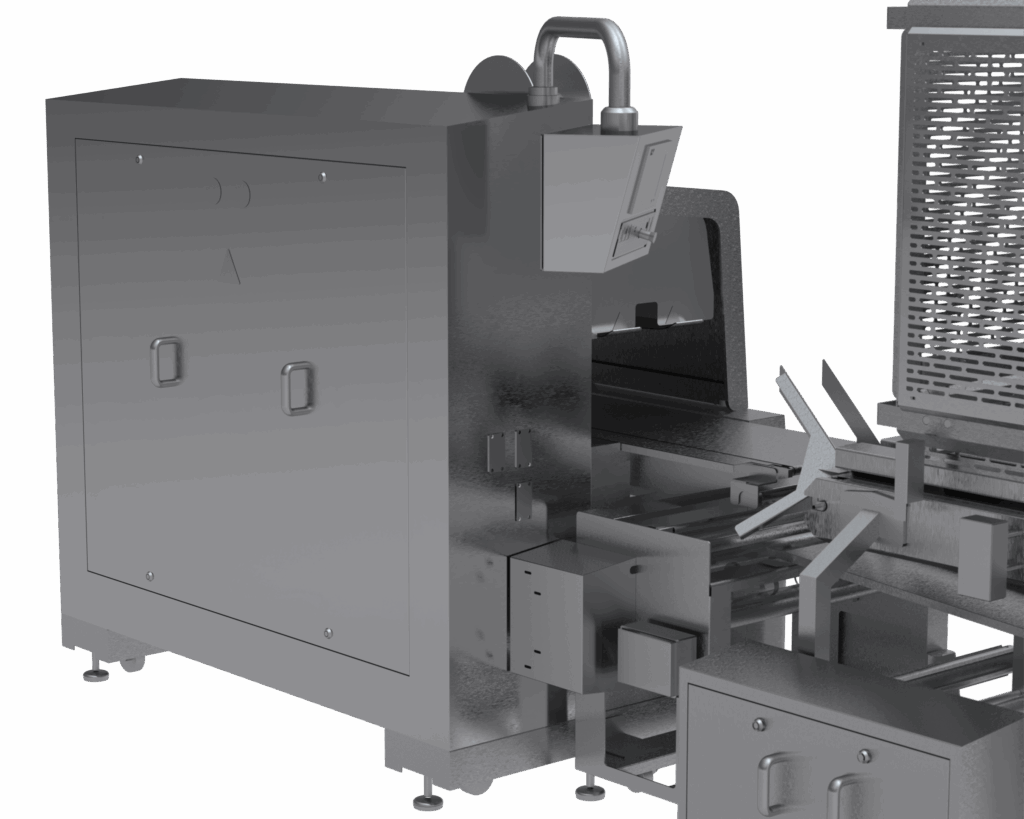

Oven Loading

Oven loading efficiently places products into your ovens for optimal baking or thermal processing. Designed to meet your specific needs, our solutions ensure superior hygiene and enhanced performance while integrating seamlessly into your production lines. Compatible with various product types (raw, frozen, etc.), they optimize production rates and deliver precise process control.

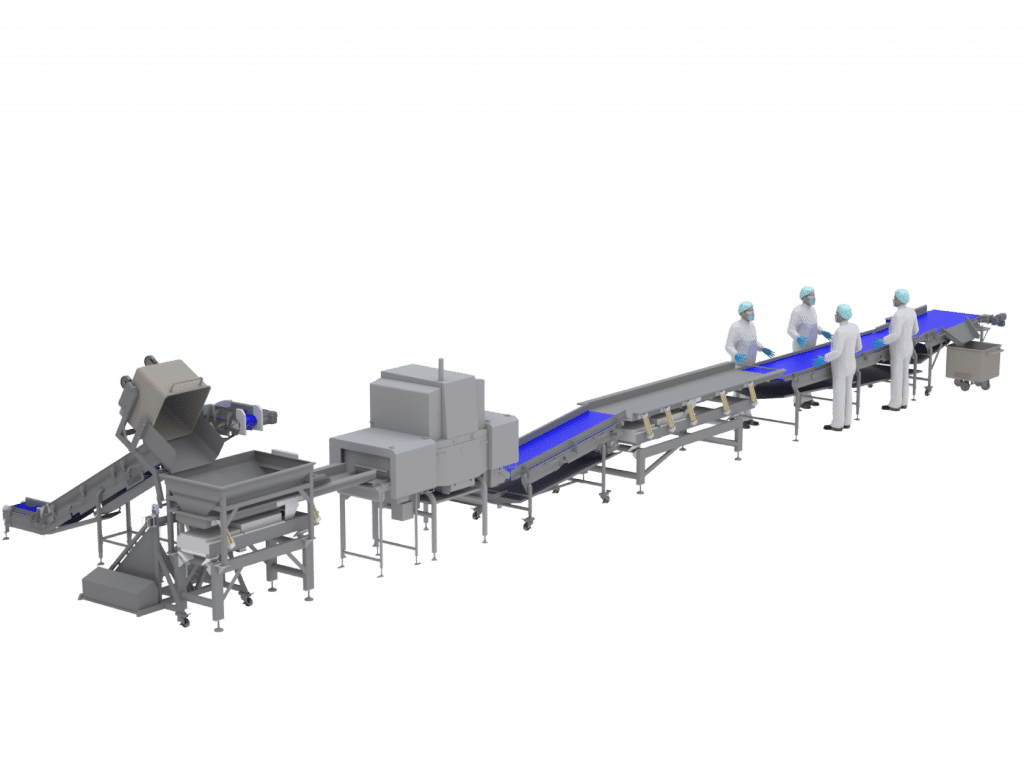

Freezer Loading

Freezer loading is a complex step that requires careful study to optimize the performance of your freezing tunnel. Our experts design tailored solutions based on your specific requirements (capacity, temperature, freezing time, etc.), using cold-resistant materials and frost-minimizing designs. Our systems include exit alignment solutions to ensure perfect product positioning and low-wrap conveyors for optimal transfer efficiency.

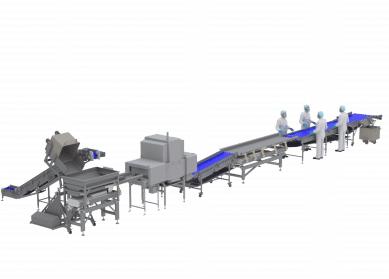

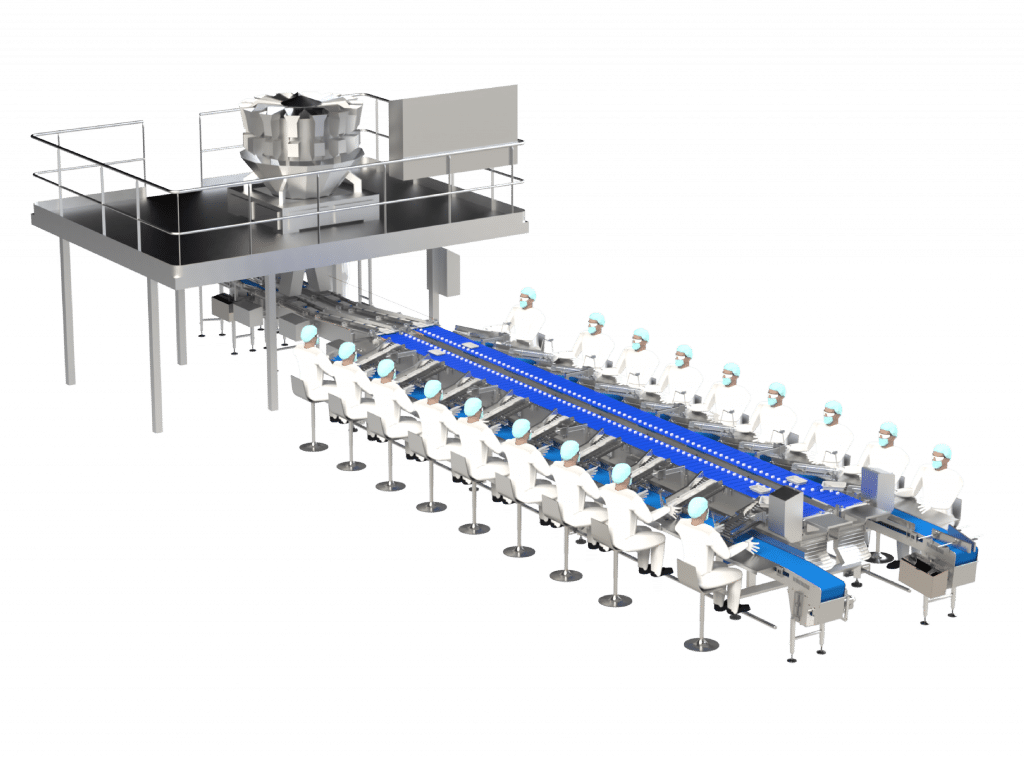

Tray Loading

Tray loading ensures smooth and continuous tray handling in your production line. Our experts design ergonomic and hygienic solutions tailored to your specific needs—whether for workstation count, available space, or production rate. Each operator station features a buffer zone storing up to 3 trays, while our AIM belt conveyors guarantee seamless tray transfer. This system enables your operators to work under optimal conditions without disrupting production flow.

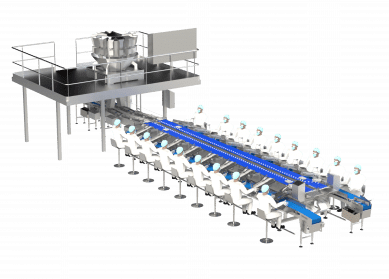

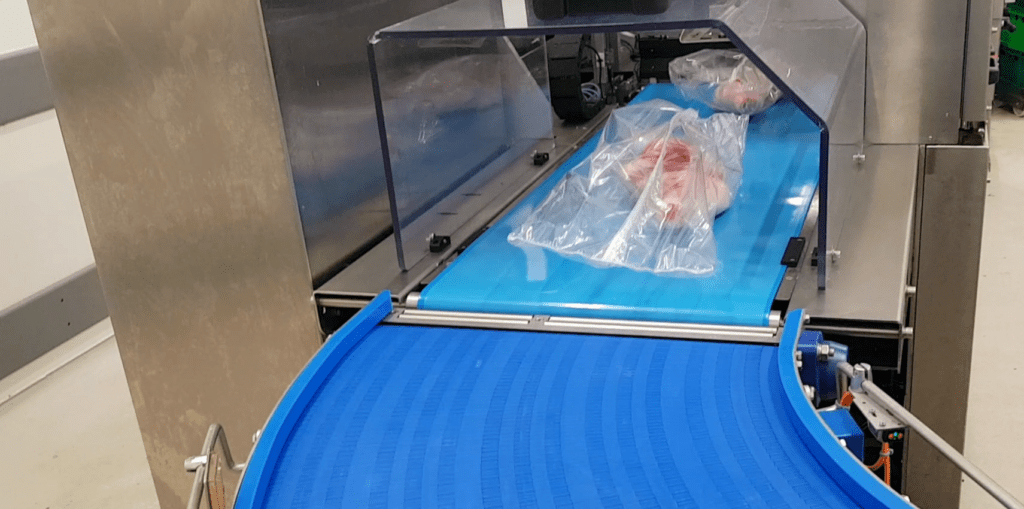

Vertical Bagger Loading

The bagging machine is an innovative solution designed to automate pouch packaging operations. Ideal for food products, it ensures precise filling and high-speed performance. Its ergonomic design optimizes floor space while simplifying production operations. Reliable and flexible, it delivers consistent quality while reducing labor costs.

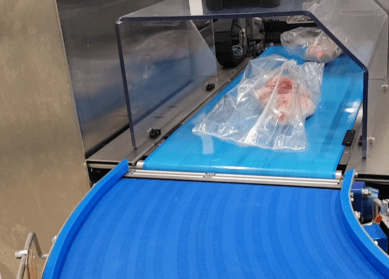

Flowpack Loading

The flow wrapper provides fast, reliable packaging solutions for a wide range of food products. Its advanced technology ensures airtight, secure wrapping while preserving product freshness and quality. Compact and flexible, it adapts to various product shapes and sizes, optimizing space and productivity. Ideal for high-speed operations, it delivers consistent performance while complying with stringent hygiene standards.

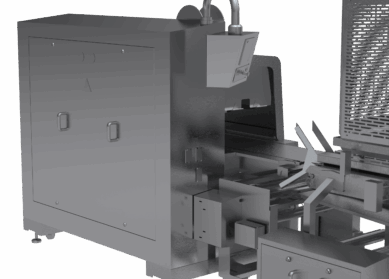

Thermoformer Loading

The thermoforming machine is essential equipment for packaging food products in plastic films. It rapidly and precisely forms, cuts, and seals packaging while ensuring perfect airtightness to maintain product quality and freshness. Designed to handle a wide variety of formats and products, the thermoformer offers maximum flexibility and easy integration into your production lines. It optimizes production rates while ensuring consistent packaging quality, thereby enhancing both efficiency and food safety.

Lidding Machine Loading

The lidding machine is the ideal packaging solution to ensure airtight sealing and product safety for your food items. It applies a protective film over containers, providing optimal preservation while maintaining freshness. Easy to integrate into your production lines, it adapts to various container types and products. Fast and precise, this system optimizes your packaging efficiency while complying with the most stringent hygiene standards.

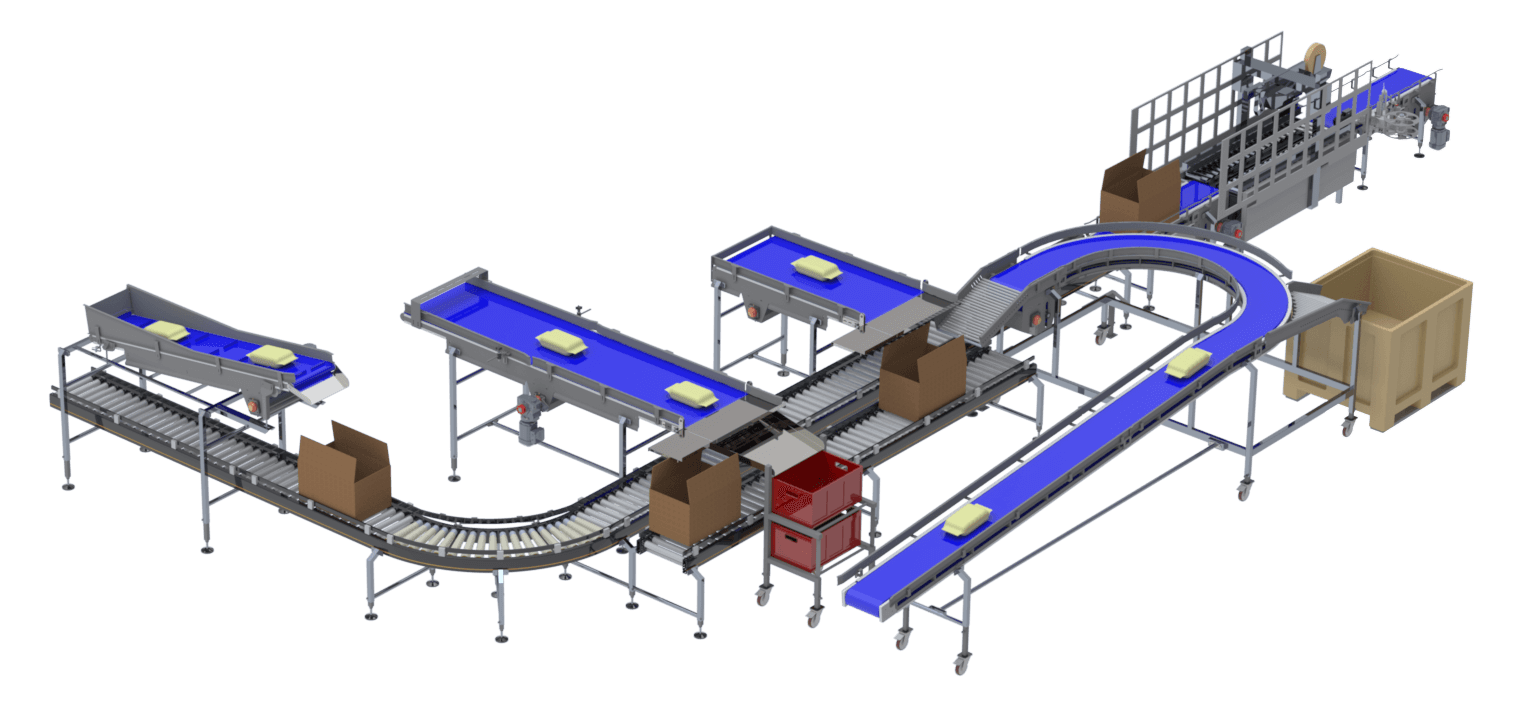

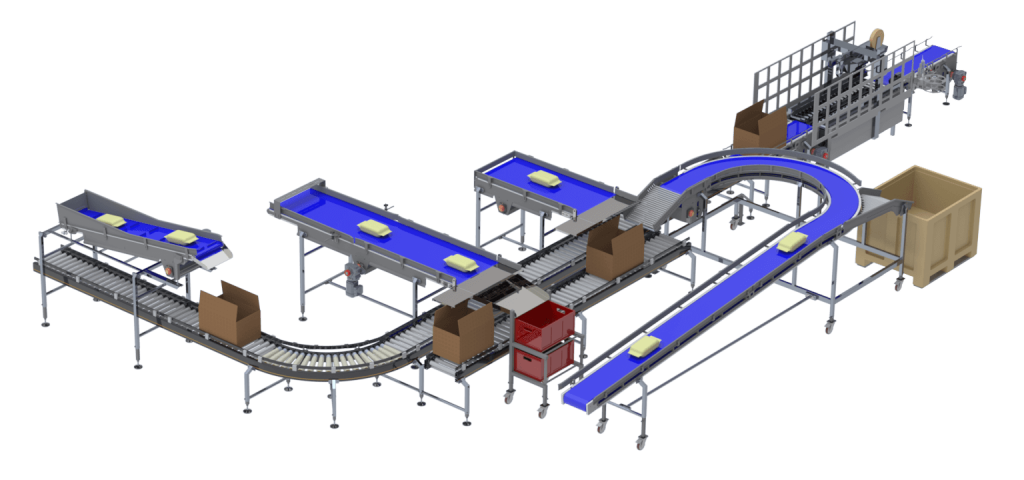

Cartons Loading

Carton loading automatically or manually inserts finished products into shipping boxes. This critical step organizes, protects, and prepares products for storage or shipment. The process can accommodate either bulk loading or orderly arrangement, depending on product characteristics and packaging requirements.

Improve Machine Availability with Our Hygienic Design

Acemia operates in the ready meals sector, in France and abroad, for both unpacked and packaged products. We can help you improve your production processes, from food preparation to tray placement and primary packaging. We offer automated handling solutions adapted to your products and their preparation.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, reducers, sensors, etc.)

- Hygienic Design+ finish: bead-blasted (ra: 0.8)

Easy to clean

Man-height equipment for easy access, inspection and cleaning.

- Tool-free removal of belts and accessories

- Storage cart available on request

NO WATER RETENTION

Open, inclined structure to avoid retention zones

No hollow tubings on any of our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures perfect cleaning of all parts in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).