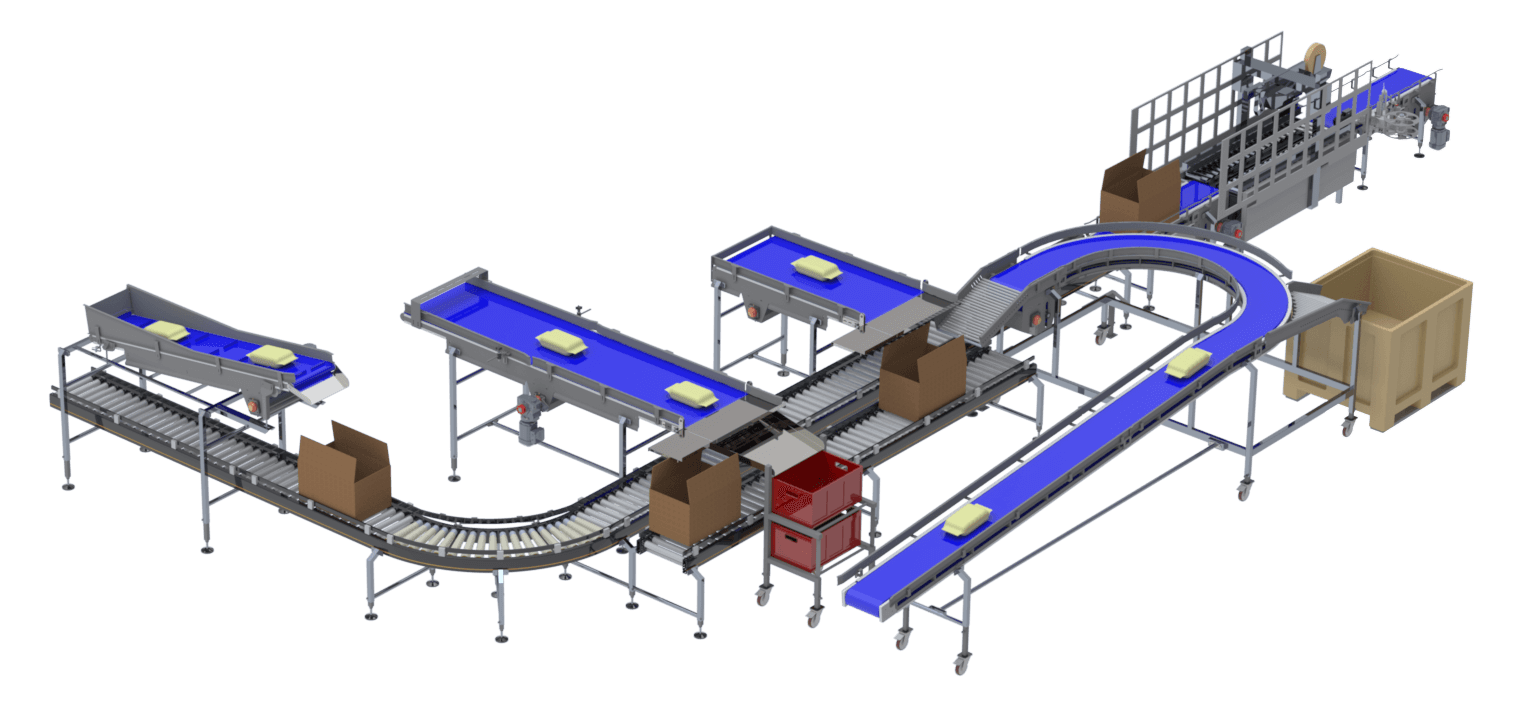

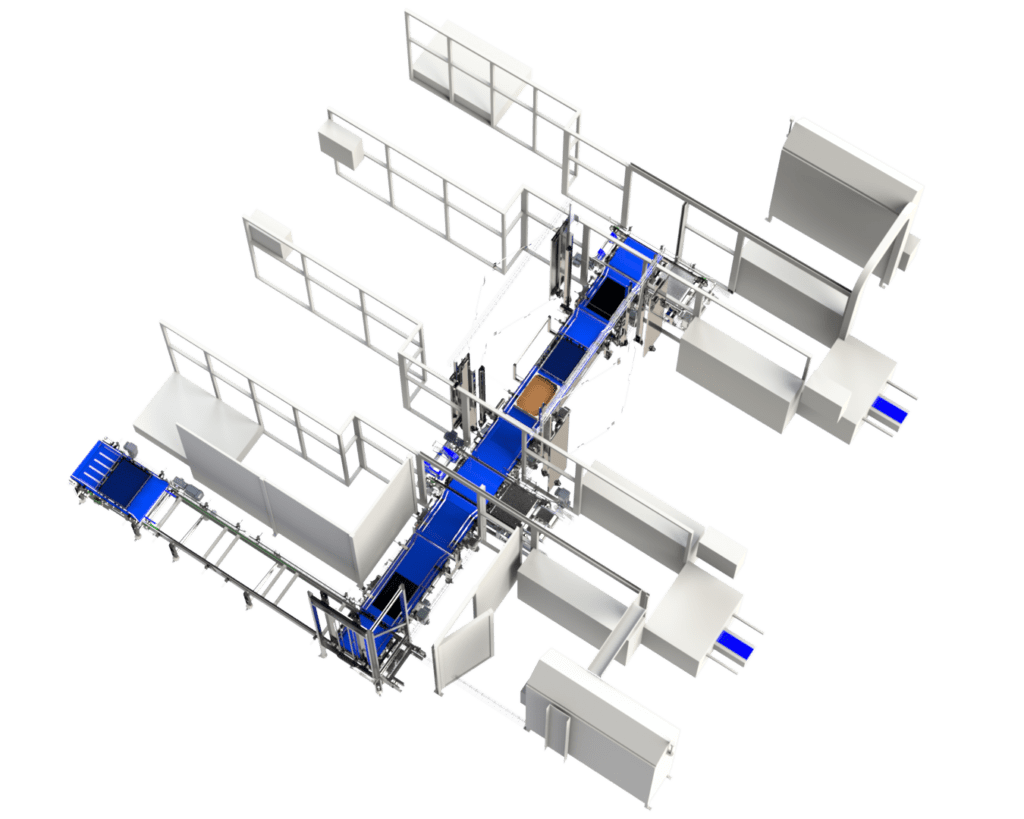

Bin Conveying

Bin conveying systems must meet various constraints: product diversity, flow organization, speed, and precision requirements. Acemia develops custom solutions to automate your parcel management, considering the specifics of your site and performance goals.

Our equipment first handles product conveyance, followed by orientation. Then, parcels are formed, weighed, labeled, and conveyed to the storage area, all within a perfectly synchronized flow. With our full mastery of automation, we help you gain reliability, speed, and traceability.

Primary Packaging

Primary packaging directly protects the product, preserving its freshness and integrity. It facilitates handling and transport within the crate conveying system, ensuring safe and efficient operations.

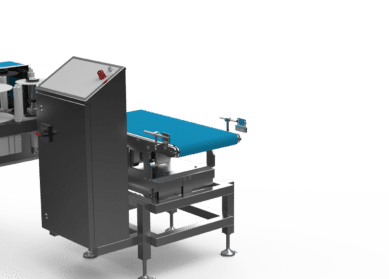

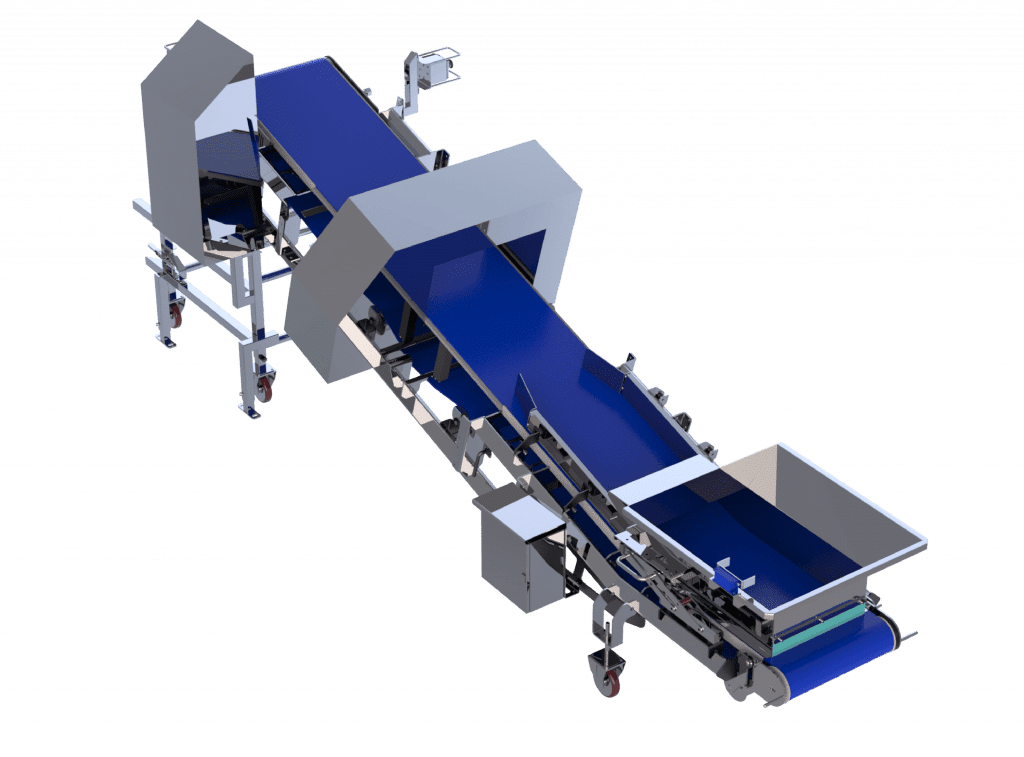

Weigh Control

Weight control verifies the weight of each crate to meet regulatory, sales, and quality requirements. It ensures load compliance, optimizes flow management, and secures handling operations.

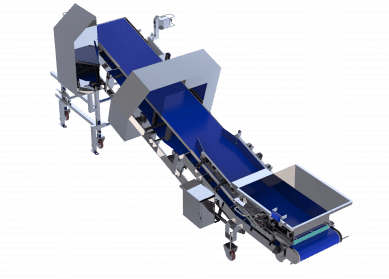

Metal Detector

The metal detector inspects each bin at a key point to detect any metallic foreign objects. It ensures food safety, complies with current standards and protects product quality.

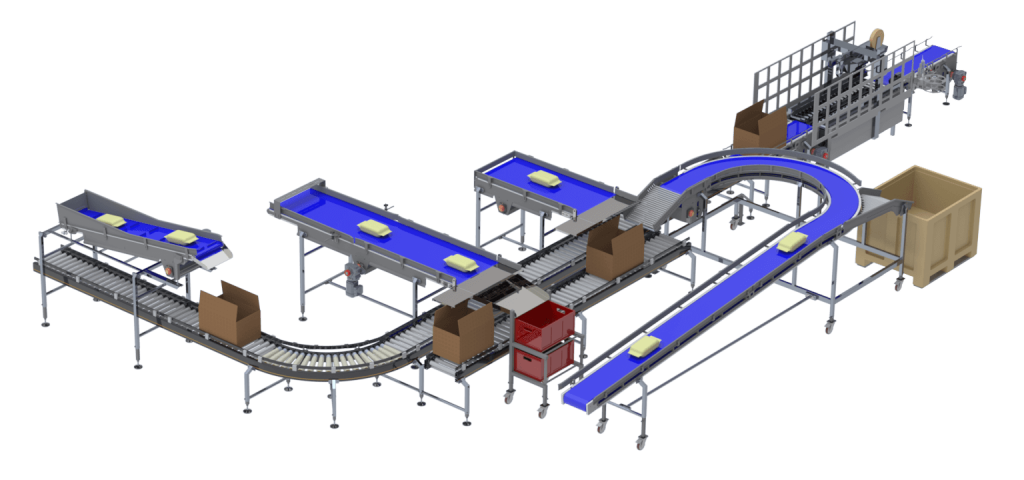

Boxing

Boxing consists of placing products into cartons for shipping or storage. This automated process ensures high efficiency by providing precise and secure carton filling while optimizing the production flow.

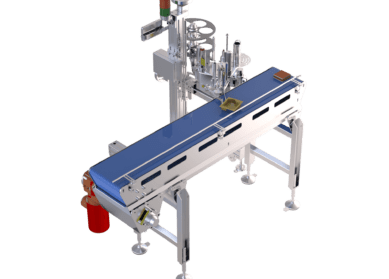

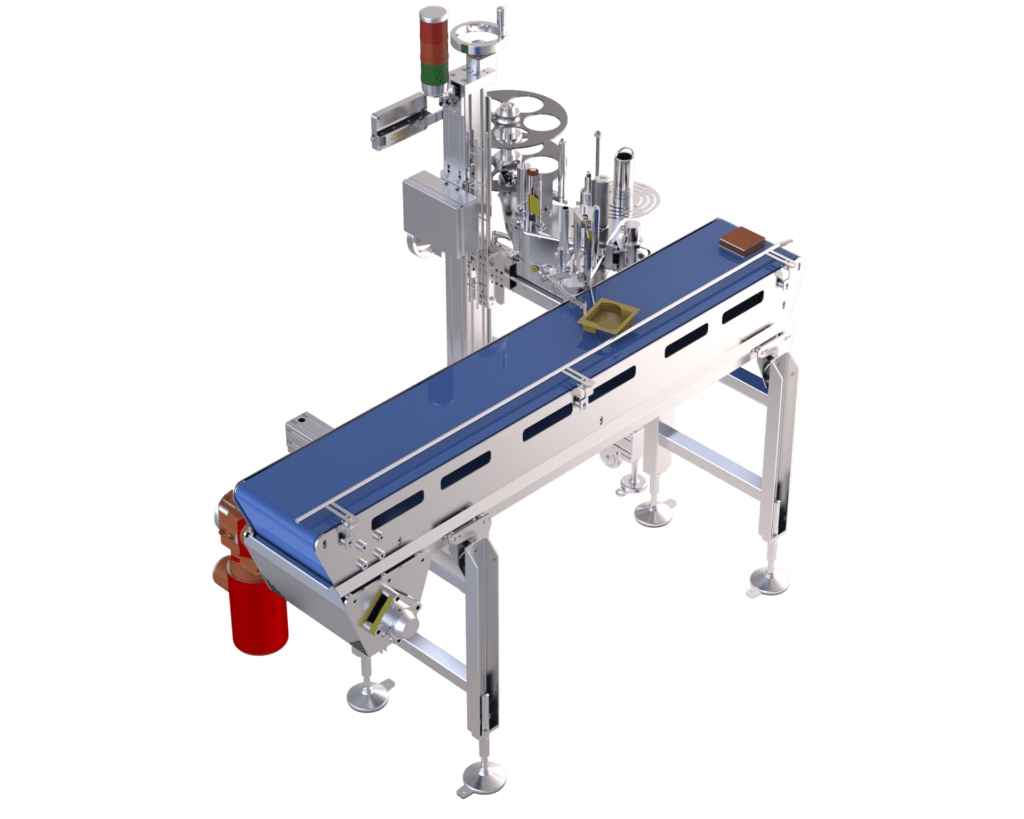

Labeling Machine

The labeling machine applies labels to cartons or bags, ensuring optimal traceability and compliance with standards.

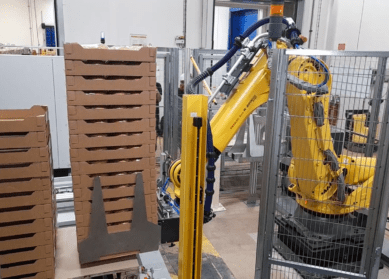

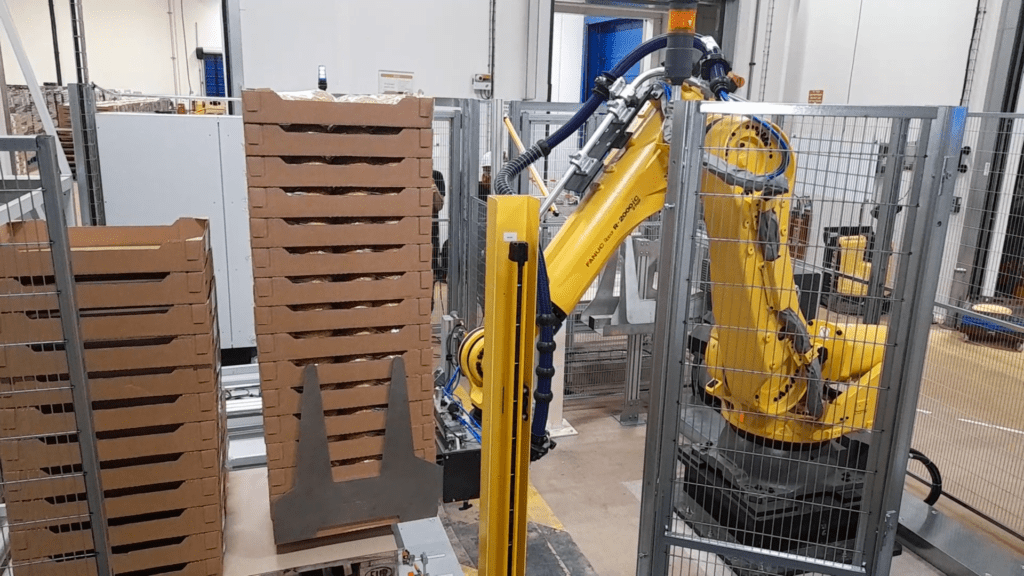

Palletizing Cell

The palletizing cell moves pallets from one area to another without manual intervention. This system optimizes flow management and improves production line efficiency.

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors, …)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).