Cleaning In Place

In a production environment that is often cold, humid, and conducive to bacterial growth, hygiene is a key concern to ensure the safety of your products and the sanitary compliance of your lines.

At Acemia, we offer a Cleaning in Place (CIP) solution that automates the cleaning process of your equipment without disassembly. Reliable, efficient, and easy to use, our system helps reduce downtime, optimize water and product usage, and ensure thorough and consistent cleaning.

Designed to integrate seamlessly into your production lines, the Acemia CIP system helps maintain a clean, safe, and compliant working environment that meets the most stringent standards of the food industry.

Automate Your Cleaning Process to Optimize Your Cleaning Operations

Designed to optimize your production, our CIP solution simplifies and automates your cleaning operations.

Able to easily connect to hot water, soap and other cleaning products, application times are guaranteed to ensure a thorough cleaning of your machines and reduce your downtime to a minimum.

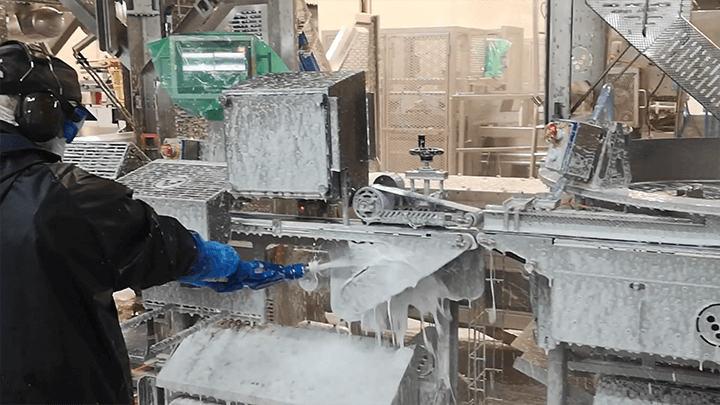

Simplify Your Operators’ Job and Improve Their Daily Life

To facilitate the daily work of your cleaning teams, our experts have developed an easy-to-use program. Our CIP allows you to automate your cleaning operations and reduce errors related to human intervention.

Thanks to our Cleaning in Place system, you will no longer need to dismantle your lines to clean them: the cleaning product is sprayed directly on the surfaces. The most difficult to access areas are no longer a problem, providing you with a gain of time, safety and efficiency.

Opt for An Environmental Friendly Solution

The good control of your water consumption is an increasingly important issue in the eyes of consumers.

With our CIP, you are now able to supervise your cleaning operations and control your consumption of water and products.

Thanks to its programmed cleaning cycles and optimized applications time, you are able to save up to 60% of water and cleaning products!

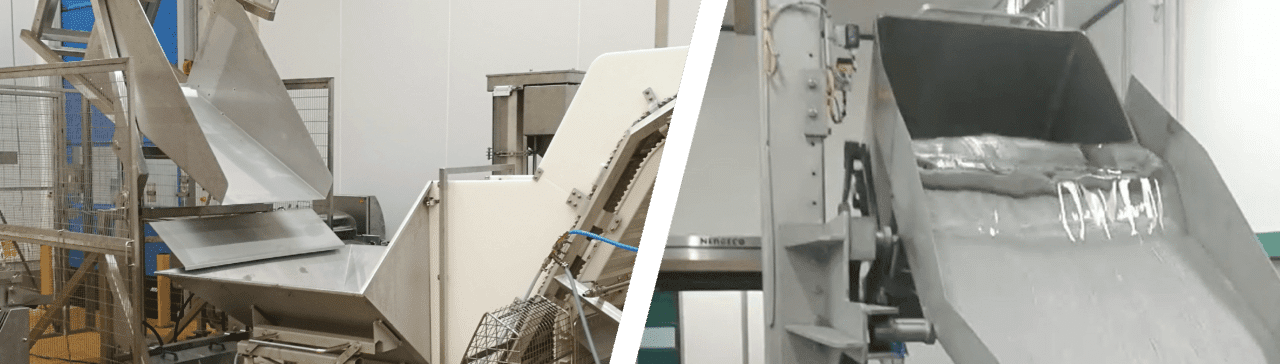

Improve Your Machine Availability with Our Hygienic Design

As food manufacturer, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, sensors, etc.)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Ground level equipment for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and sloped structure to avoid retention zones

No hollow tubings on all our equipment

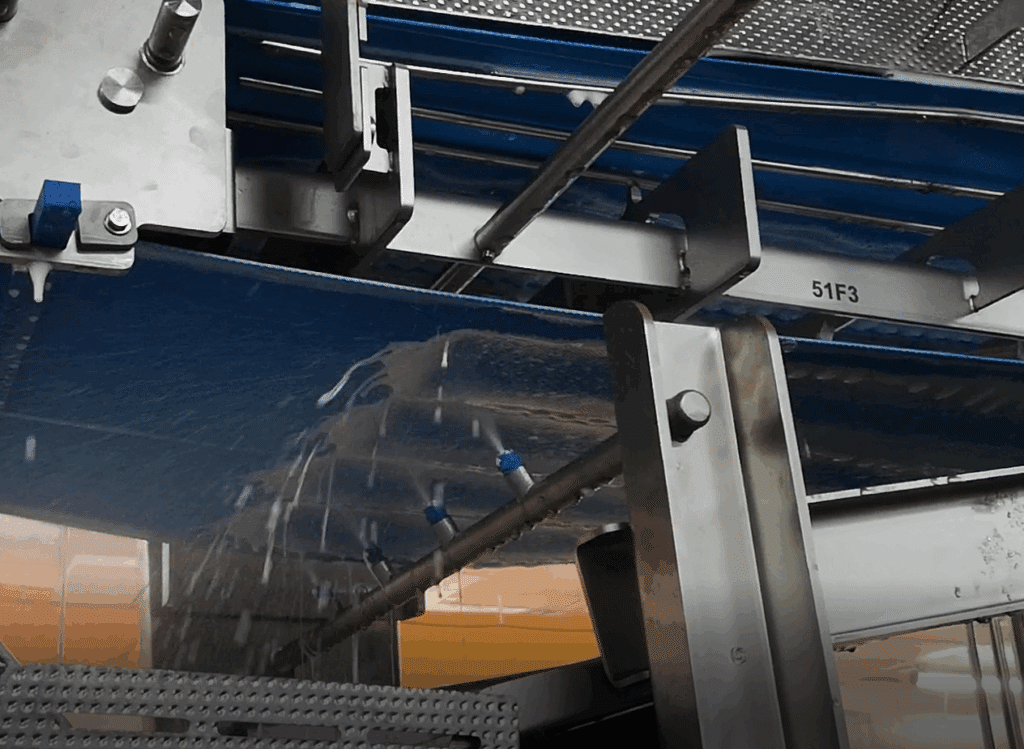

WATER AND SANITATION PRODUCTS SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Improve Your Operators’ Performance with Safe and Ergonomic Workstations

We are aware of the potential risks of musculoskeletal disorders (MSD) associated with repetitive work in the food industry.

We know that your commitment to the safety and health of your employees is essential to creating high quality products. That’s why our handling equipment is designed to minimize the risk of MSDs and improve the safety of our operators.

Our experts have developed real expertise in designing state-of-the-art equipment to ensure that your operators can work safely, while guaranteeing superior production. Our material handling equipment is equipped with ergonomic features to help operators work comfortably and efficiently.