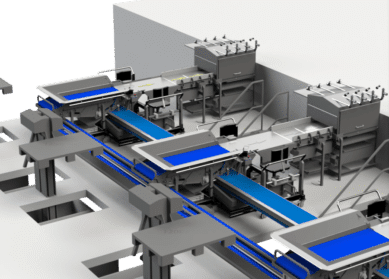

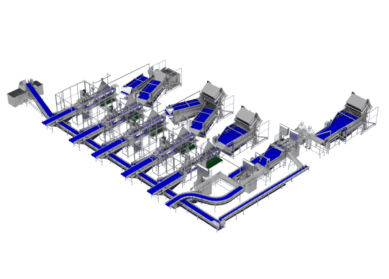

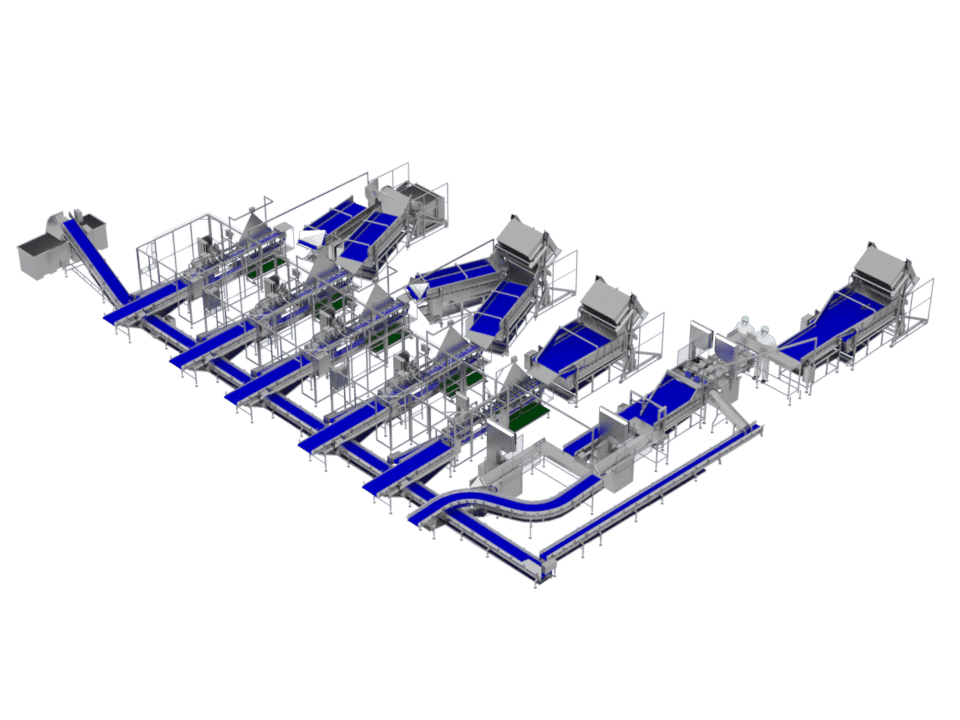

Acemia designs a custom salmon line for processing and packaging, tailored to the specific needs of the food industry.

Among the equipment offered, we provide icebreaking stations that ensure delicate handling of the product while meeting hygiene standards. Our conveying systems allow smooth and secure transportation of salmon through the various stages of production. Each solution is designed to optimize efficiency while ensuring the impeccable quality of the final product.

Acemia is committed to integrating cutting-edge technologies to meet the performance, flexibility, and safety requirements of salmon producers.

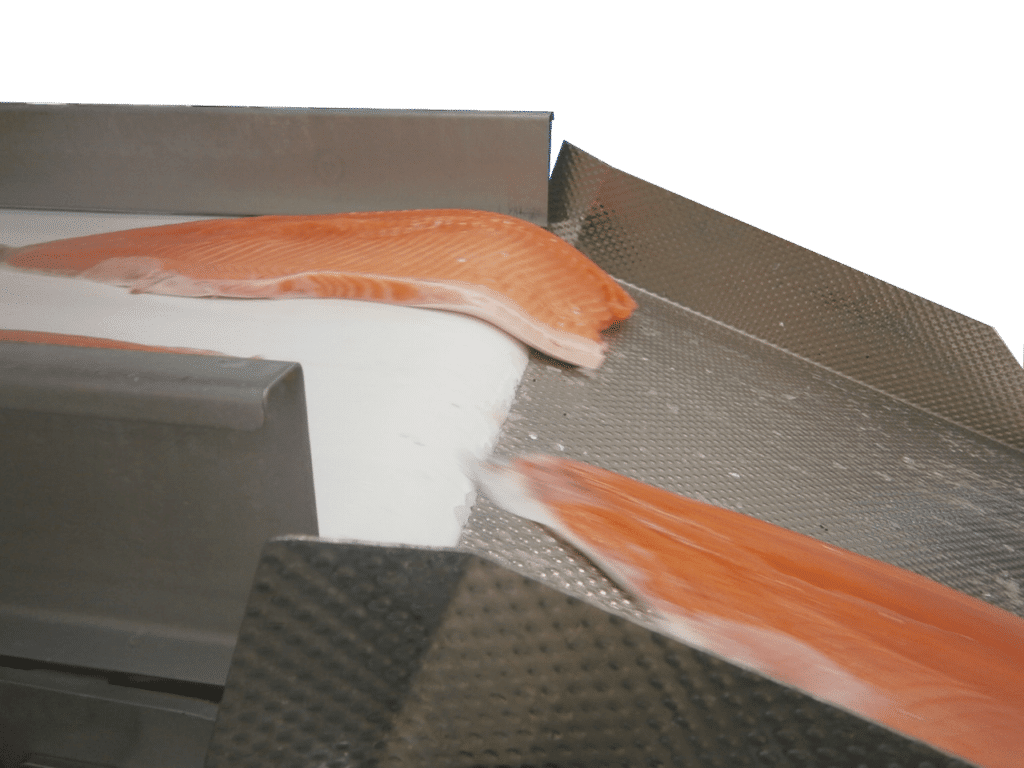

Icebreaking Station

Designed to improve working conditions and productivity, our deglazing station ensures smooth and secure handling of frozen products. Ergonomic and compliant with sanitary standards, it easily integrates into your lines to guarantee optimal treatment of raw materials.

Fish Cutting

Acemia offers automated solutions for fish cutting, including frozen tuna, combining precision, consistency, and safety. With technology tailored to the specific needs of the food industry, our system optimizes throughput while adhering to the strictest hygiene standards.

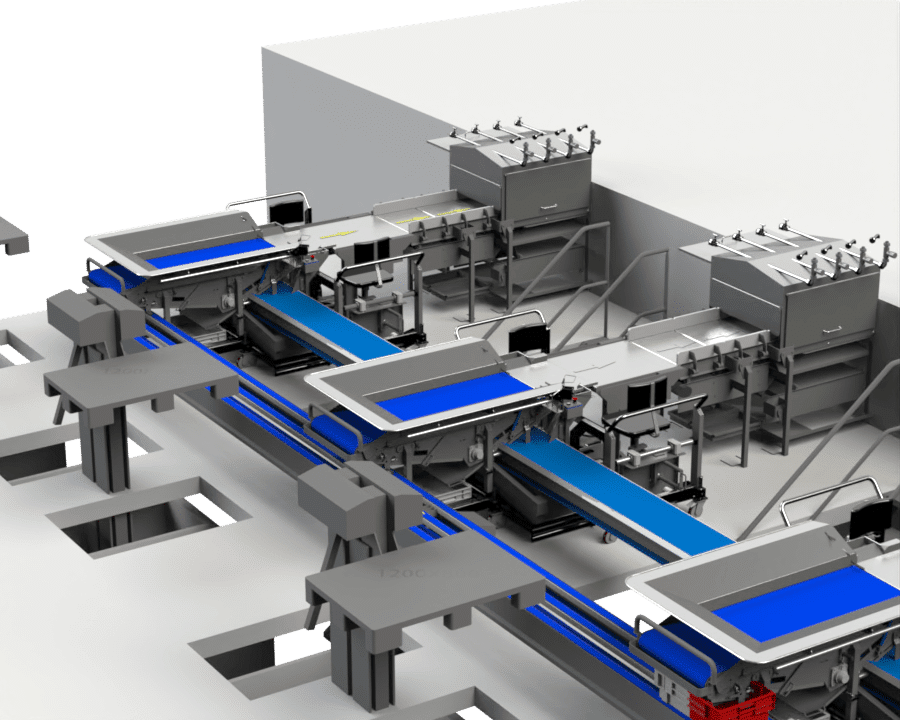

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors, …)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).