Discover our solution for fresh or frozen pizza production and packing, an innovative technology to automate your industrial process. Designed to optimize the efficiency of your production, this solution ensures the quality and integrity of your products while streamlining resource management and maximizing productivity.

Efficient Manufacturing and Packaging Process

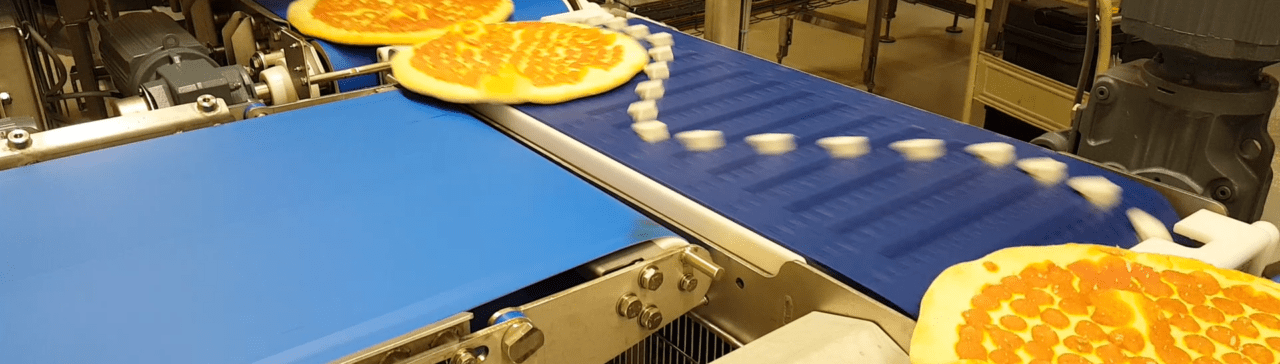

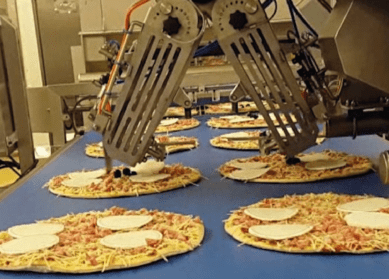

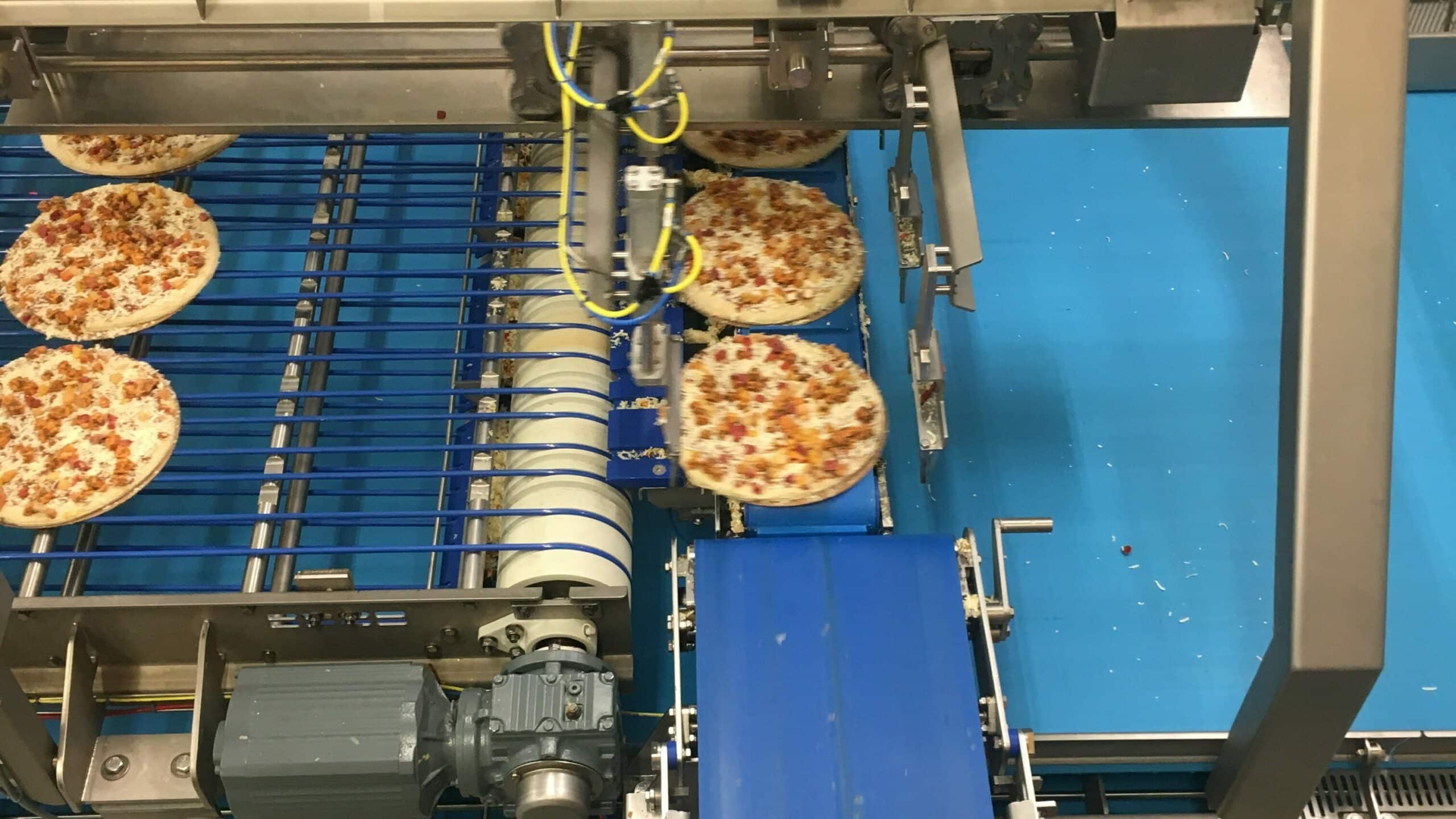

The process begins with the precise alignment of the pizza dough and baking in the oven. The sauce is applied accurately using dosing machines, while a cellular counting system ensures uniform distribution of toppings. After passing through the first freezing tunnel, the pizzas are directed to a second blast freezing tunnel.

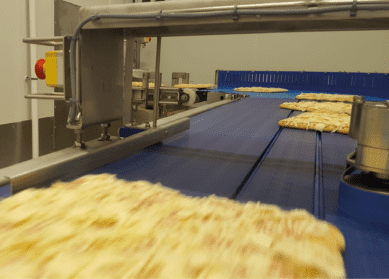

The frozen pizzas are then moved to the packaging line where an automatic packaging system wraps them in suitable film. They are then grouped into batches according to your commercial requirements and moved to the palletizing area, where an automated stacking system prepares the packages for shipping.

Optimization of Production Flow and Advanced Automation

To ensure a smooth and continuous production flow, our solution integrates automated equipment that precisely regulates the pace at each key stage. The oven and freezer inlet/outlet systems perfectly synchronize transfers, while the tray counting system ensures precise product control.

Acemia designed this solution to automate the entire process – from cooking to final palletization. This approach optimizes both the quality of the pizzas and the efficiency of your production, with equipment that complies with the strictest food safety standards.

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel 304L solution

IP69K

- Hygienic Design+ finish: Microblasting (0.8)

EASY TO CLEAN

Man-height equipment for easy access, monitoring and sanitation.

Automated cleaning with our Cleaning-in-Place system.

ZERO WATER RETENTION

Open, inclined structure to avoid retention zones.

No hollow bodies on any of our equipment.

WATER SAVING AND

HYGIENE

Down to 50% reduction in water and disinfection product consumption thanks to CIP.