Discover Acemia’s chubs and slicks sorting and packing line, an innovative and comprehensive solution for automating your production. Designed to enhance the efficiency of your packaging processes, this line ensures the integrity of your products while optimizing time and resource management.

Efficient Sorting and Packaging Process

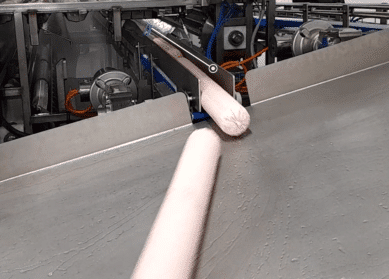

The process begins with the transportation of the chubs and slicks onto the automated sorting line, where each product is carefully sorted and categorized according to size and specification. This step allows the chubs and slicks to be separated quickly and efficiently, minimizing human error and maximizing productivity.

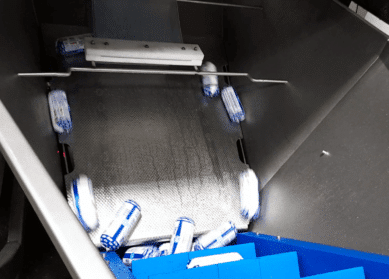

Once sorted, the chubs and slicks are directed to the packaging stations, where our automated packaging machines ensure careful and secure packaging of each product, meeting the requirements of the food industry. Thanks to secondary packing loaders and modern packaging machines, each chub or slick is perfectly packaged ensuring easy handling and optimal preservation.

Optimization of Production Flow and Full Automation

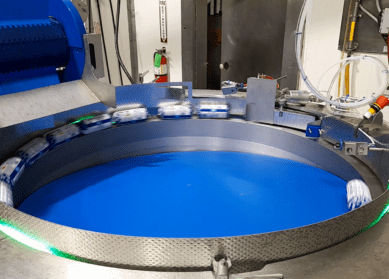

To ensure a smooth and continuous production flow, we have implemented a vibrating buffer that effectively regulate the production rate throughout the entire line. Coupled with a centrifuge machine and a secondary packing loader, this solution guarantees high productivity while reducing the risk of product damage.

Acemia focuses on automating every step of the sorting and packing line to improve not only the final product quality but also the overall efficiency of your production chain. Our solutions comply with all safety and hygiene standards in the food industry, ensuring optimal results at every stage of chubs and slicks production.

Improve Machine Availability with Our Hygienic Design

Acemia operates in the ready meals sector, in France and abroad, for both unpacked and packaged products. We can help you improve your production processes, from food preparation to tray placement and primary packaging. We offer automated handling solutions adapted to your products and their preparation.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, reducers, sensors, etc.)

- Hygienic Design+ finish: bead-blasted (ra: 0.8)

Easy to clean

Man-height equipment for easy access, inspection and cleaning.

- Tool-free removal of belts and accessories

- Storage cart available on request

NO WATER RETENTION

Open, inclined structure to avoid retention zones

No hollow tubings on any of our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures perfect cleaning of all parts in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Chubs and Slicks Line

Chubs and Slicks Line