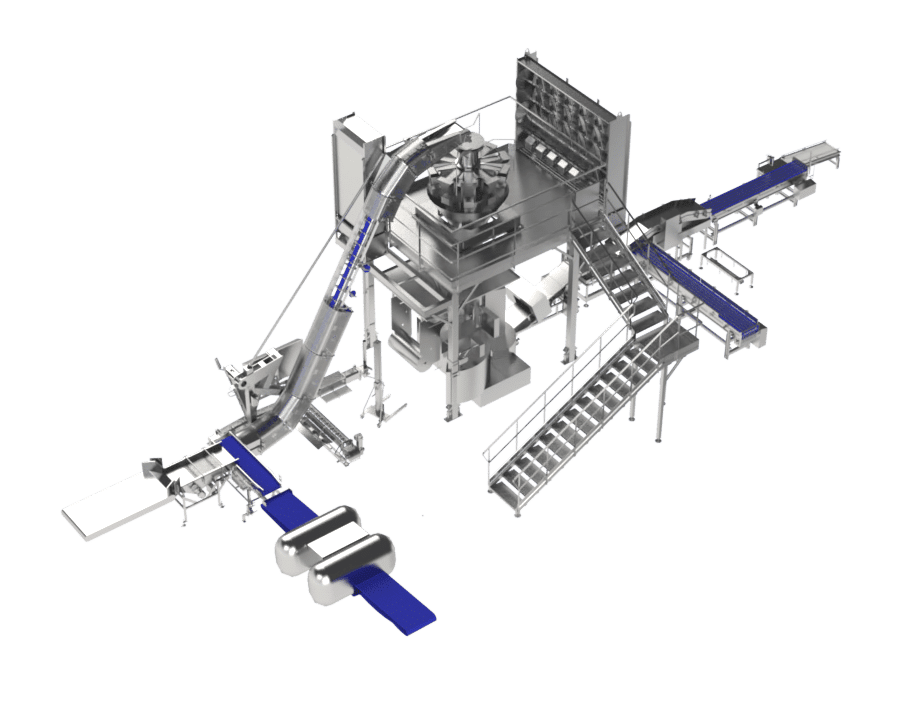

Acemia designs optimized processing and packaging lines for the production of bacon bits from pork belly.

This complete lardon line streamlines the processing and packaging workflow, maximizing efficiency, accuracy, and the quality of the final product.

By integrating advanced equipment at every stage, from industrial graters to thermoformers, Acemia ensures performance and flexibility tailored to the demands of the food industry.

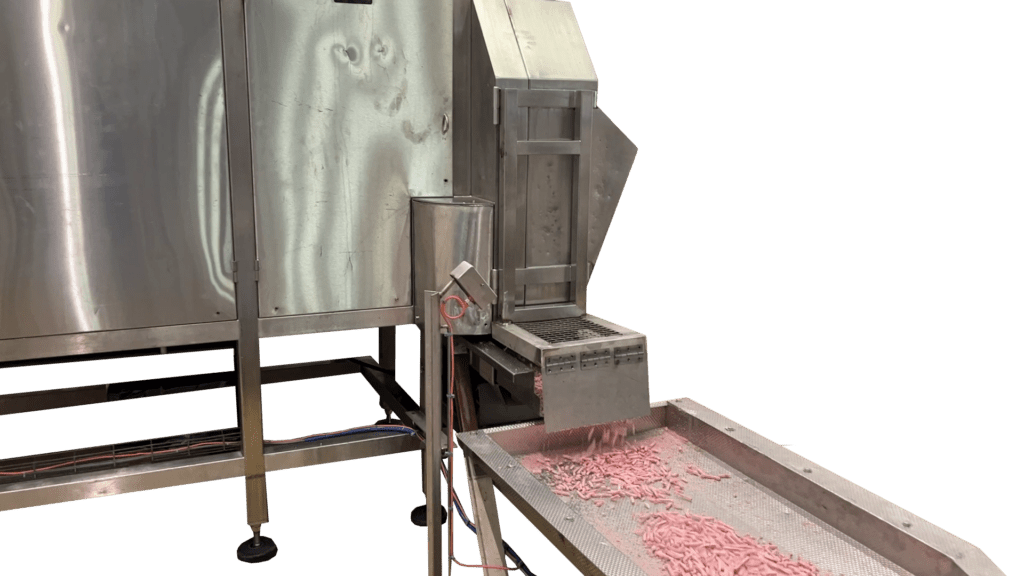

Grater Loading

Our conveyors feed pork bellies to the industrial grater. This state-of-the-art equipment transforms pork belly into lardons of various calibers, meeting a variety of production and market needs.

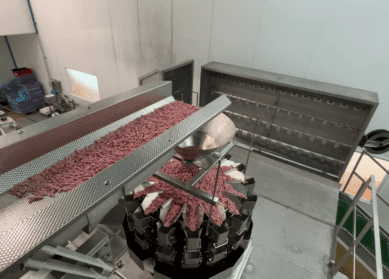

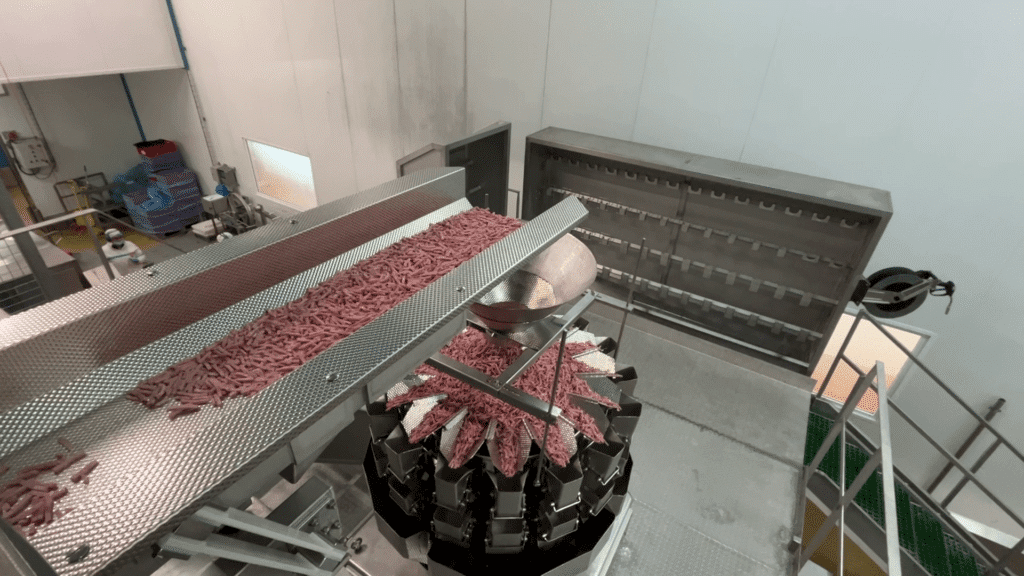

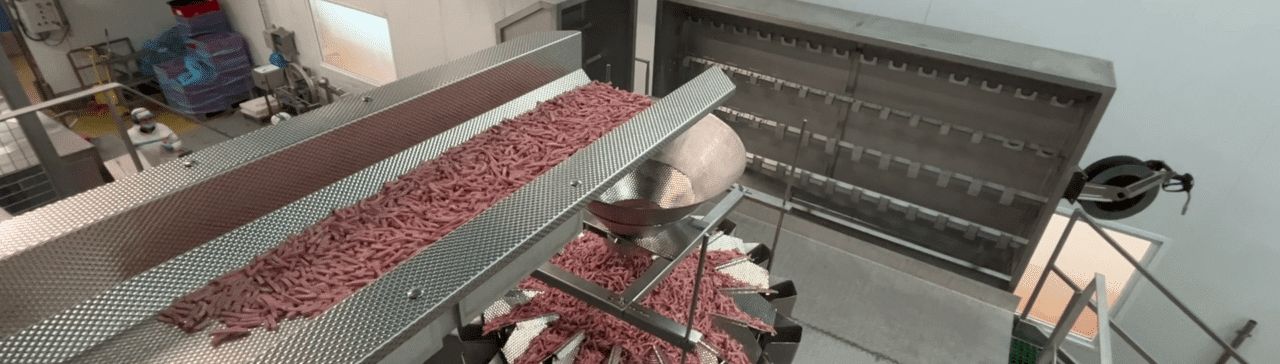

Multihead Weigher Loading

Once grated, the lardons are conveyed via an S-shaped conveyor to vibrating conveyors installed on a platform. These conveyors ensure a regular, controlled feed, guaranteeing a continuous flow of product to the multihead weigher.

Vibratory conveyors are designed to transport products in a uniform, controlled manner, eliminating the speed and flow variations often encountered in manual feeding systems. The use of vibratory conveyors adds an extra dimension by providing an oscillating motion that helps separate items and align them optimally for weighing.

Thermoformer/Traysealer Loading

The lardons leave the multihead weigher ready for packaging. Acemia’s solution provides two packaging options depending on the specific needs of your production: thermoforming or sealing.

With the thermoformer, hermetically sealed, customized packaging is created for optimum preservation, while the tray sealer enables fast, efficient packaging, ideal for large-scale production lines.

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors…)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

Lardon Line

Lardon Line