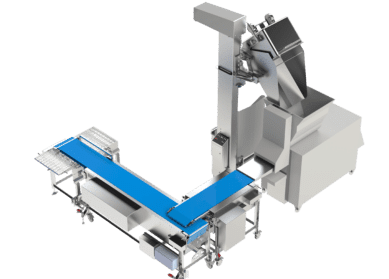

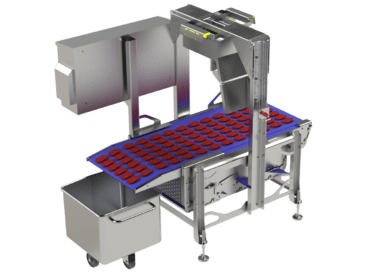

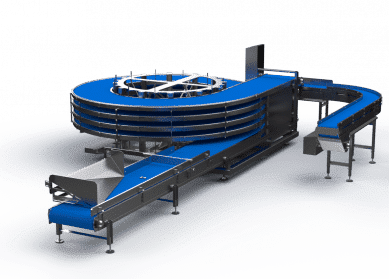

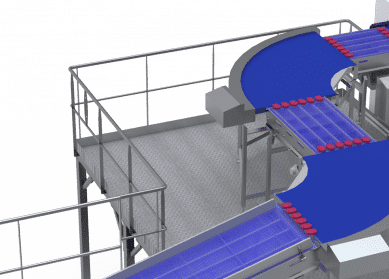

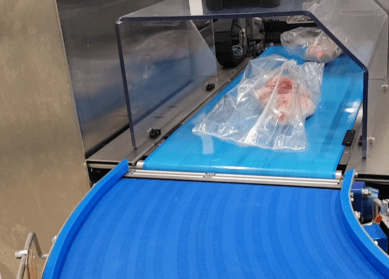

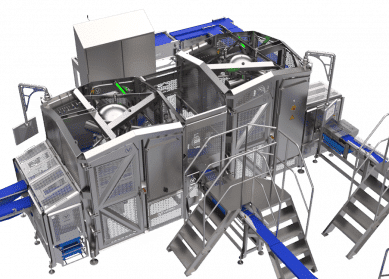

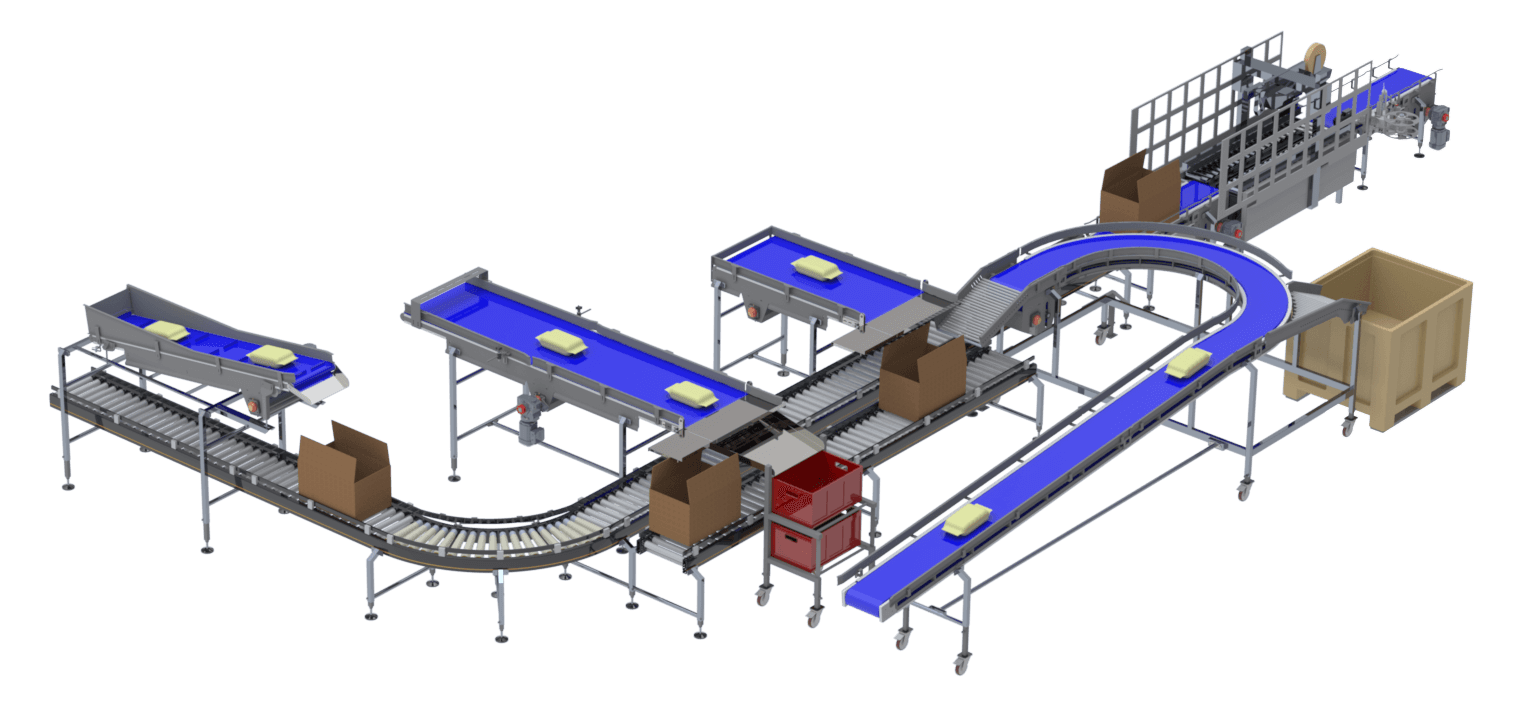

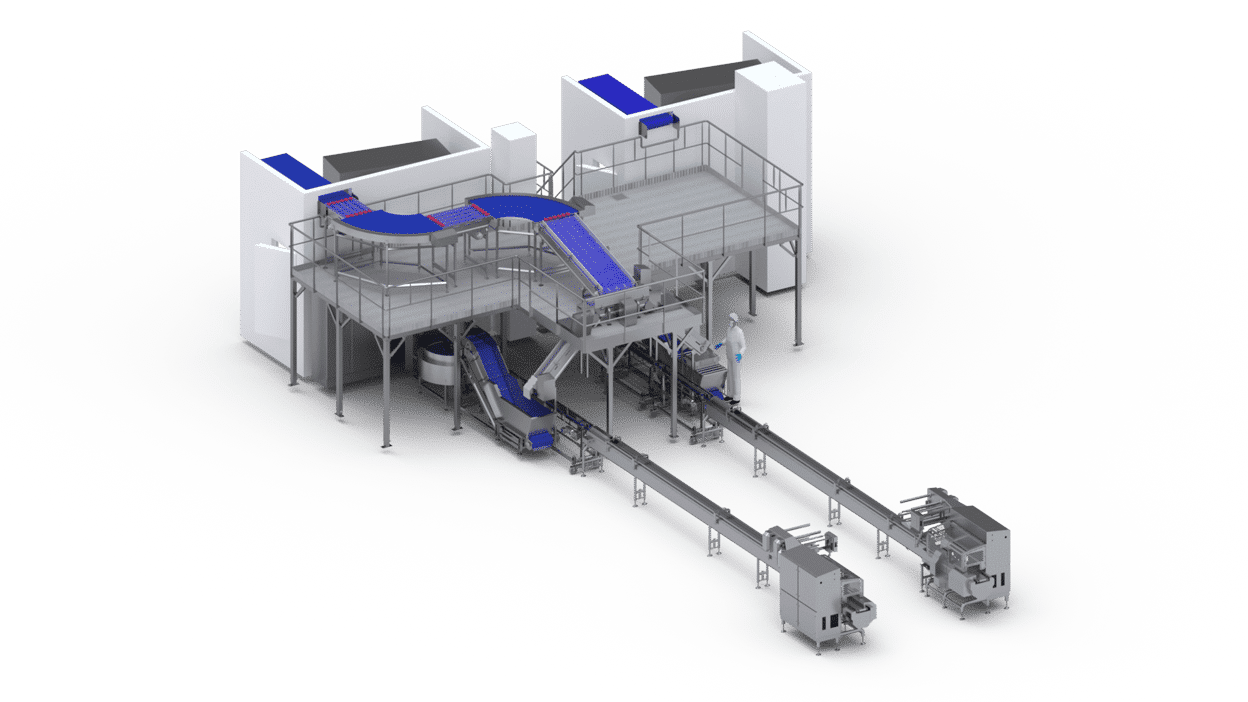

Discover Acemia’s IQF burger line, a complete and modular solution for automating the production of elaborated products. Designed to adapt to the specific requirements of each plant and each product, our line ensures precise sorting and careful handling of frozen steaks, while maximizing your productivity.

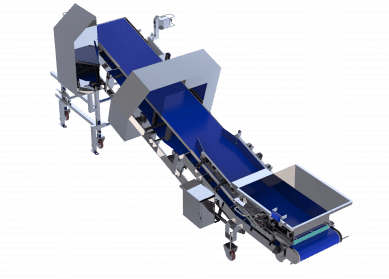

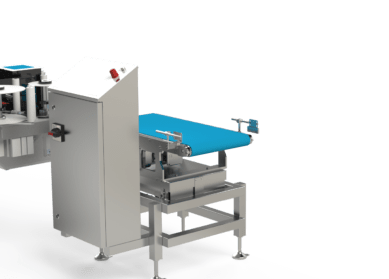

Thanks to our advanced technologies — including retractable conveyors for controlled and smooth transfer, the RAID module for precise product placement, and optical laser sorting to detect and reject non-compliant products — Acemia offers you a flexible and high-performance solution.

Our lines are designed to optimize the efficiency of your processes while ensuring a high level of hygiene, safety and product quality.

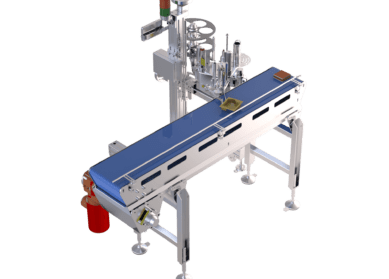

Improve Machine Availability with Our Hygienic Design

Acemia operates in the ready meals sector, in France and abroad, for both unpacked and packaged products. We can help you improve your production processes, from food preparation to tray placement and primary packaging. We offer automated handling solutions adapted to your products and their preparation.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, reducers, sensors, etc.)

- Hygienic Design+ finish: bead-blasted (ra: 0.8)

Easy to clean

Man-height equipment for easy access, inspection and cleaning.

- Tool-free removal of belts and accessories

- Storage cart available on request

NO WATER RETENTION

Open, inclined structure to avoid retention zones

No hollow tubings on any of our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures perfect cleaning of all parts in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).

IQF Burger Line

IQF Burger Line