Optimizing production flows is a major challenge today to remain competitive. Yet, even the best-designed systems can experience slowdowns or temporary interruptions. Buffer zones play a strategic role by smoothing these variations and ensuring the continuity of the flow. When well designed, they become a true lever of productivity and reliability: a simulation study showed that increasing the capacity of these zones could improve the overall efficiency of a production line by over 11%.

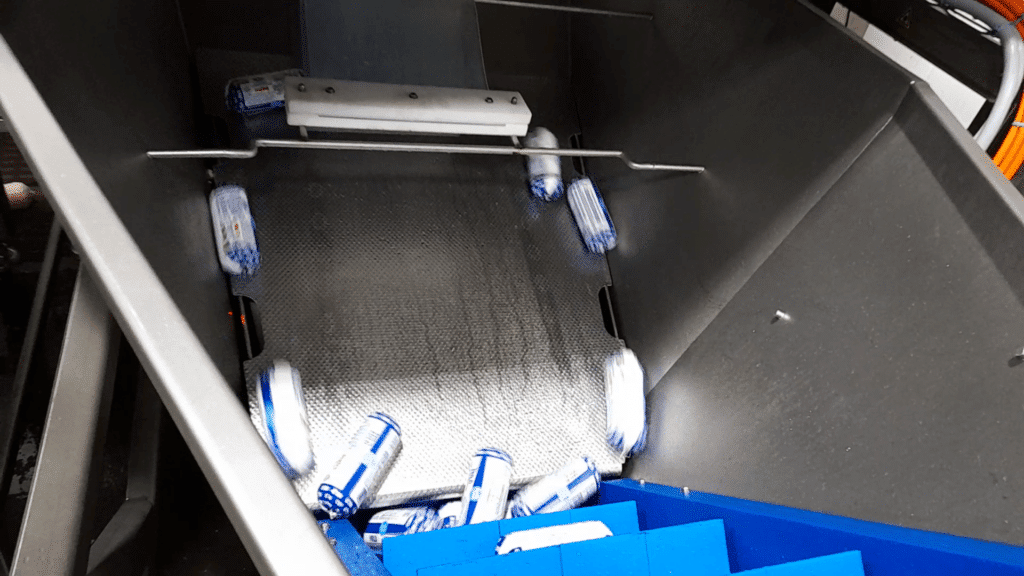

Buffer zones are intermediate spaces in a production line where products can be temporarily stored before moving on to the next stage. Their goal: absorb fluctuations in pace, prevent machine stoppages, and reduce waste.

In an environment where lines must handle an increasing variety of products, these zones allow for:

To be truly effective, buffer zones must be adapted to the nature of the products and the line’s rhythm. Key points to consider:

When well designed, buffer zones increase line reliability, reduce material losses, and improve overall efficiency. They also offer a strategic advantage: the ability to absorb production peaks or cadence variations without requiring heavy investment.

In a modern food processing facility, flow smoothness is crucial. Buffer zones are not just empty spaces: they are a real tool for industrial optimization and agility. Combined with material handling and automation, they ensure that every product arrives at the right place, at the right time, without quality loss or cadence interruption.

Do your lines have properly adapted buffer zones? Contact us to analyze your production flow and identify potential optimization levers.