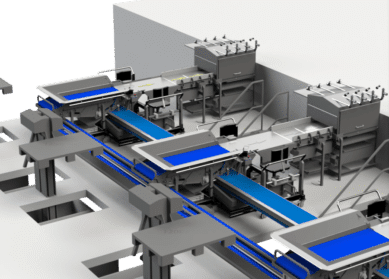

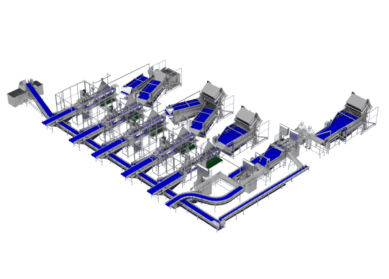

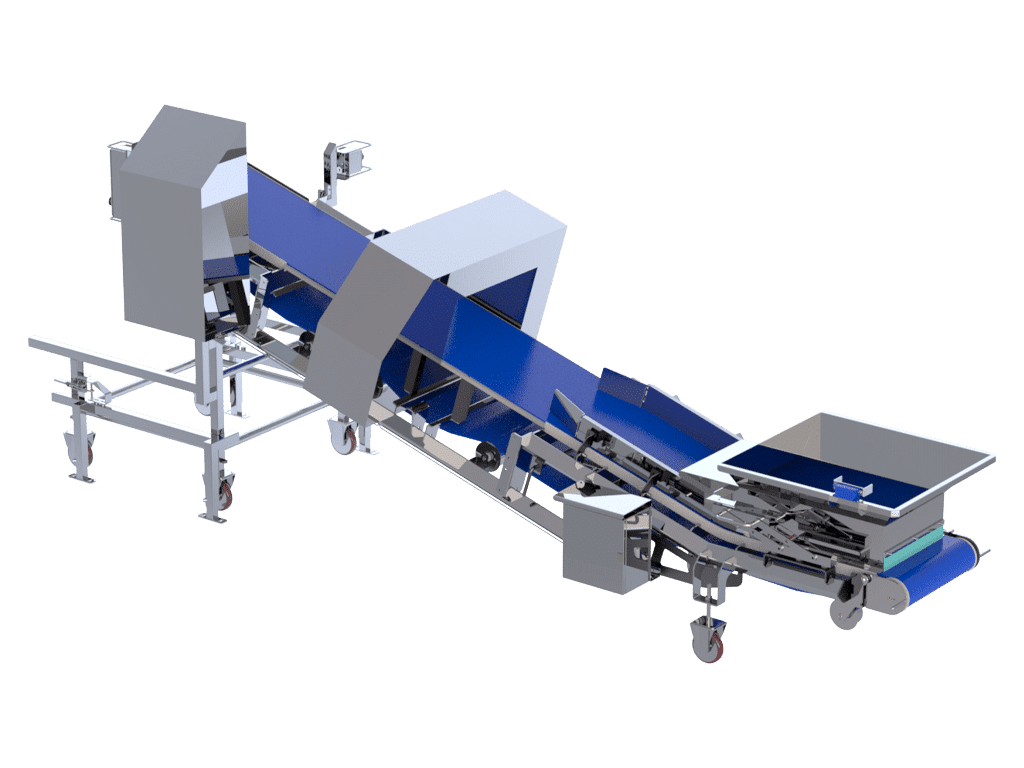

Acemia designs a white fish line, tailored to meet the specific requirements of the food processing industry. Thanks to our custom solutions, you benefit from a smooth process—from cutting to the transfer of fillets—while meeting the strictest hygiene standards.

Our equipment enables precise and safe handling of products, while improving both productivity and filleting quality. Easily integrated into your existing facilities, they address the challenges of throughput, flexibility, and performance.

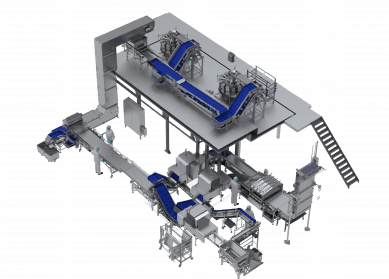

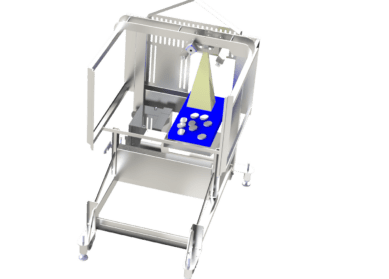

Improve Your Machine Availability with Our Hygienic Design

As an actor in the food industry, cleaning is a crucial step in your production process. You must be uncompromising about the hygiene level of your lines! Our hygienic design solution helps you to exceed your cleaning requirements.

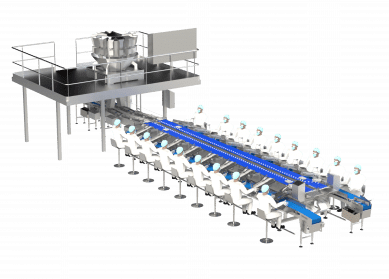

HYGIENIC MATERIALS

100% stainless steel solution

IP69K (motors,

reducers, sensors, …)

- Hygienic Design+ finish: Microblasting (ra: 0.8)

EASY TO CLEAN

Equipment at ground level for easy access, control and cleaning

- Removal of belts and accessories without tools

- Storage cart available on request

NO WATER RETENTION

Open and inclined structure to avoid any retention zones

No hollow bodies on all our equipment

WATER AND SANITATION PRODUCT SAVINGS

Our CIP system ensures a perfect cleaning of the elements in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).