Equipment Integration

At Acemia, we deliver tailored, end-to-end solutions for integrating high-performance equipment, designed to meet your exact production needs. Whether you require multi-head weighers, vertical baggers, metal detectors, checkweighers, case erectors/sealers, flow wrappers, labeling systems or lidding machines, we provide robust, reliable systems to enhance the efficiency and quality of your production line.

Our integration expertise ensures each solution is adapted to your unique constraints—whether in production flow, product type, or hygiene standards. We commit to flexible, modular, and scalable systems, delivering peak performance, precision, and long-term ROI.

Trust Acemia to seamlessly integrate state-of-the-art equipment into your production process—boosting efficiency, ensuring compliance, and elevating your quality standards.

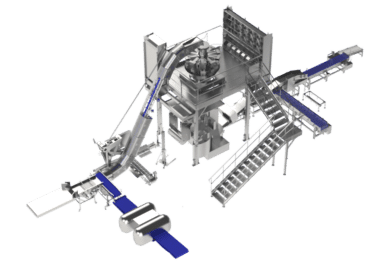

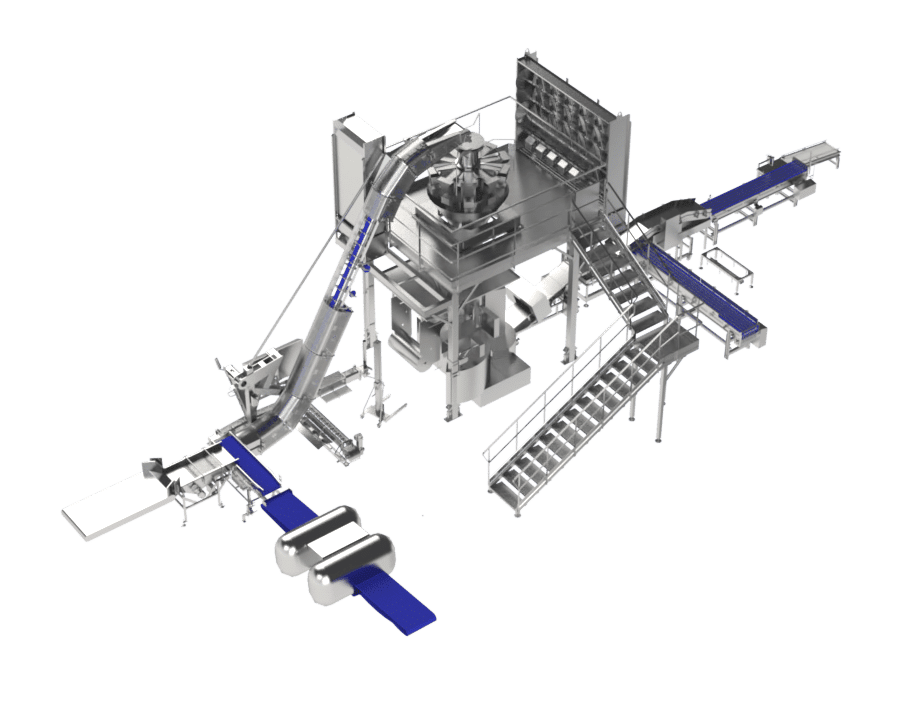

Multihead Weigher

The multihead weigher ensures precise and reliable weighing for a wide range of products. It easily adapts to your specific needs and optimizes production efficiency. This flexible solution guarantees consistent quality while meeting strict hygiene standards. Easy to integrate into your production lines, the multi-head weigher improves portion control and helps reduce costs.

Vertical Bagging Machine

The vertical bagging machine is an innovative solution designed to automate pouch packaging operations. Ideal for food products, it ensures precise filling and high-speed performance. Its ergonomic design optimizes floor space while simplifying production operations. Reliable and flexible, it delivers consistent quality while reducing labor costs.

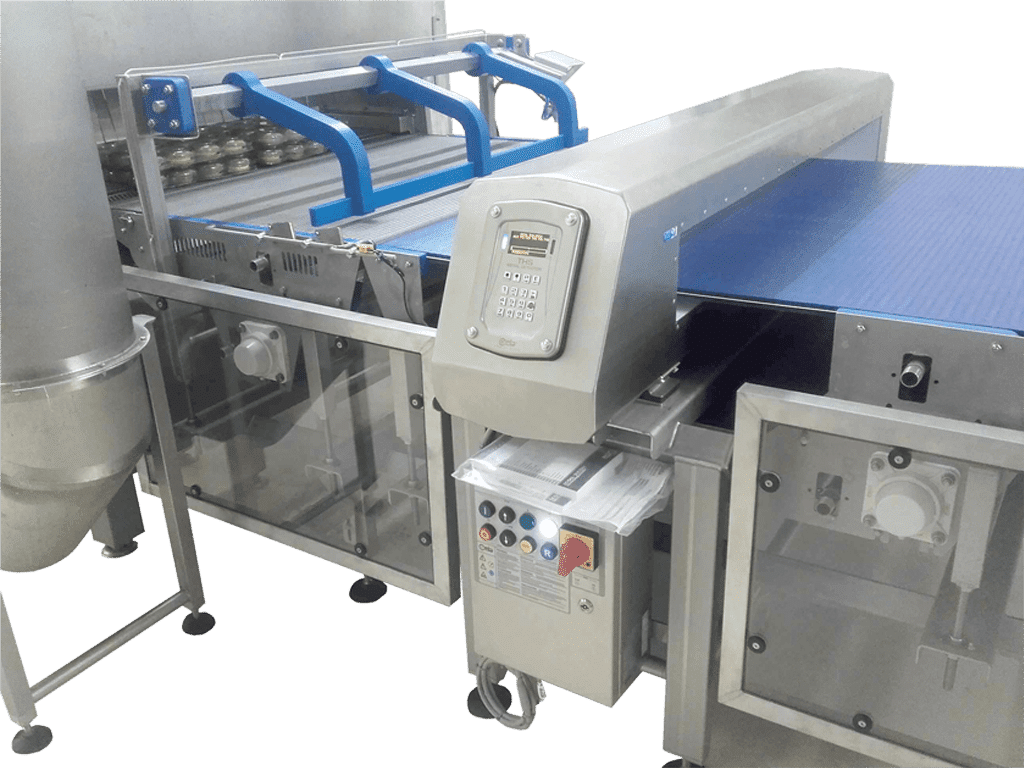

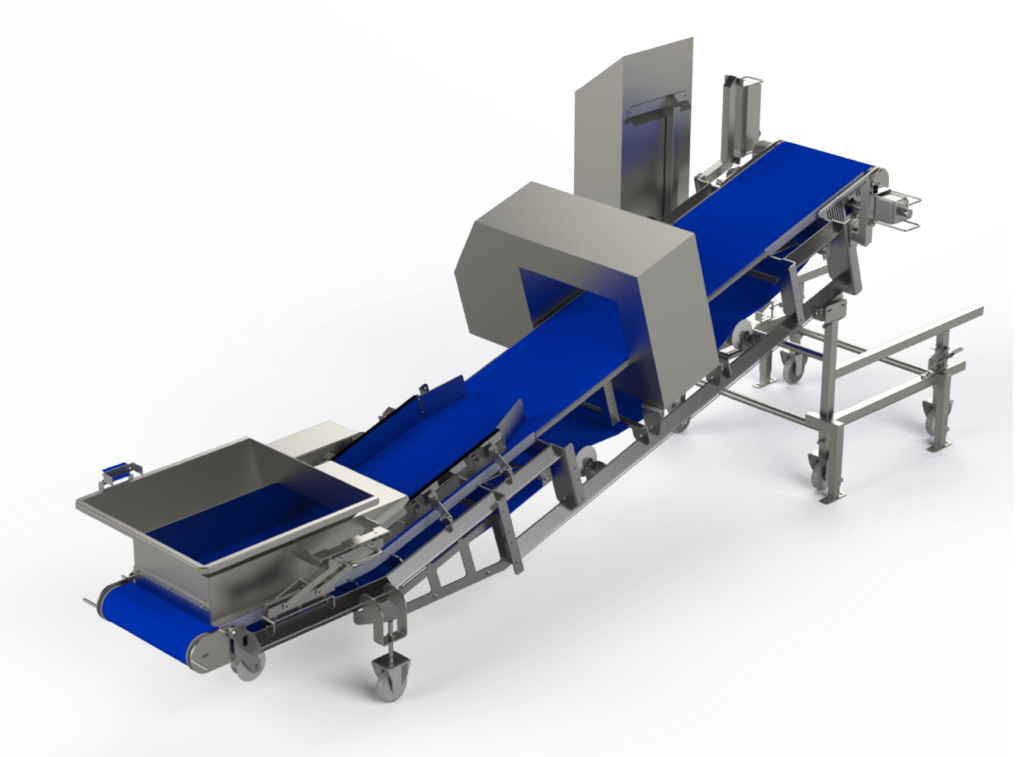

Metal Detector

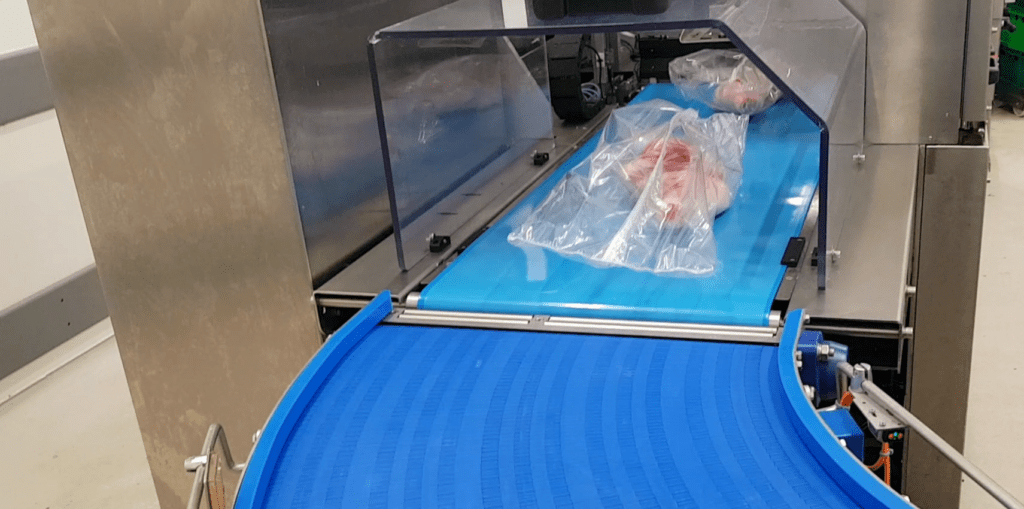

The metal particle detector is integrated into a conveyor equipped with a specific support plate. Installed in-line, it identifies the presence of metallic particles – whether ferrous or non-ferrous – within the product. If metal is detected, the affected product is automatically ejected into a secure chute.

We work with the leading suppliers on the market to integrate metal detection and X-ray inspection equipment. The most efficient and suitable system is selected based on your specifications.

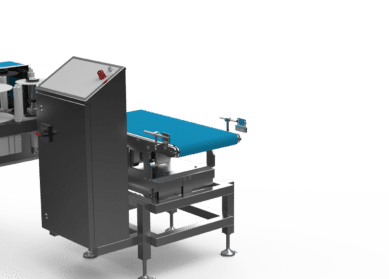

Checkweigher

The checkweigher is designed to optimize quality control on your production lines. It enables automatic product sorting by weight, ensuring compliance with your production criteria. Fast and precise, it integrates easily into various manufacturing processes while offering maximum flexibility to handle different product types. This solution helps improve your line efficiency while reducing waste and ensuring consistent quality.

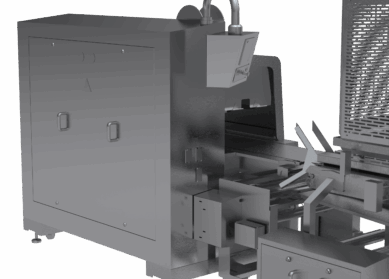

Case Erectors/Sealers

The case erector/sealer is engineered to streamline your packaging operations with speed and efficiency. It automates both case forming and sealing processes, replacing traditionally manual and time-consuming tasks. Designed for high-volume production, this solution ensures optimal case stability, even in high-speed environments. By enhancing your packaging line efficiency, it saves valuable time while improving product storage and transportation safety and reliability.

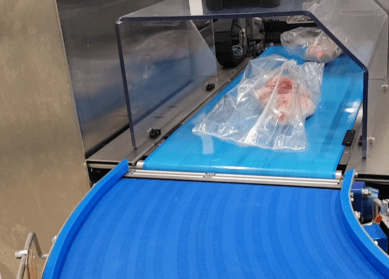

Flowpack

The flowpack provides fast, reliable packaging solutions for a wide range of food products. Its advanced technology ensures airtight, secure wrapping while preserving product freshness and quality. Compact and flexible, it adapts to various product shapes and sizes, optimizing space and productivity. Ideal for high-speed operations, it delivers consistent performance while complying with stringent hygiene standards.

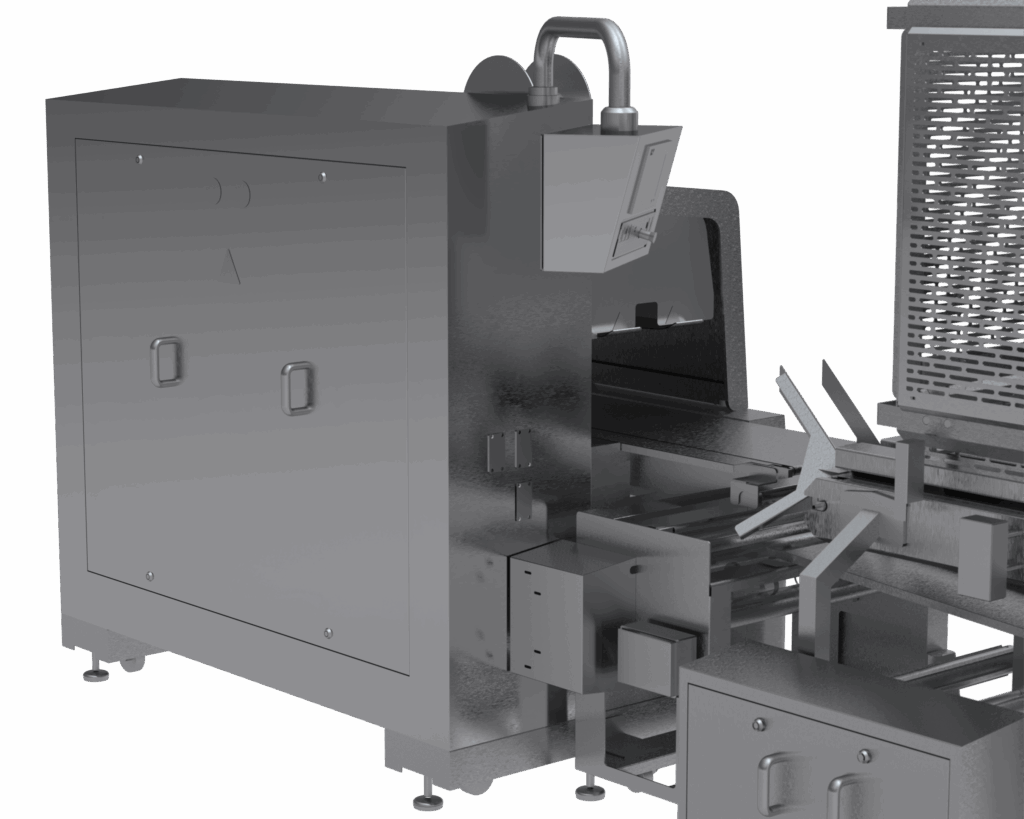

Thermoformer

The thermoforming machine is essential equipment for packaging food products in plastic films. It rapidly and precisely forms, cuts, and seals packaging while ensuring perfect airtightness to maintain product quality and freshness. Designed to handle a wide variety of formats and products, the thermoformer offers maximum flexibility and easy integration into your production lines. It optimizes production rates while ensuring consistent packaging quality, thereby enhancing both efficiency and food safety.

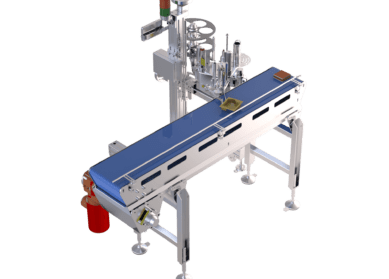

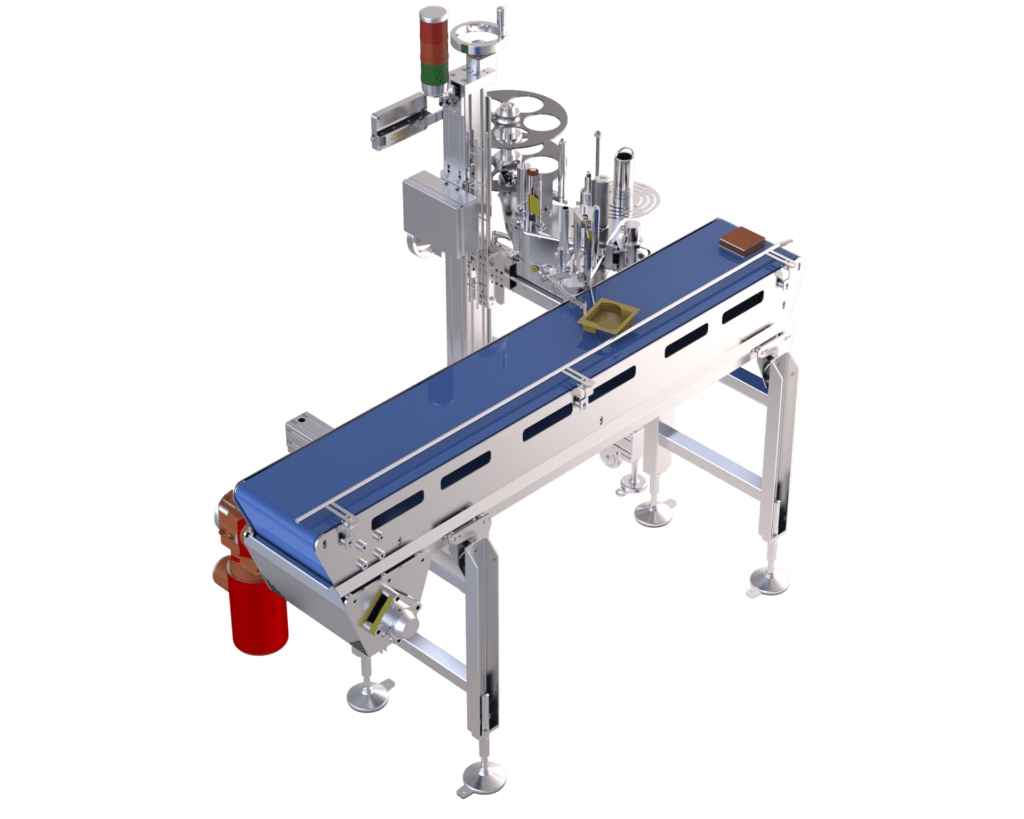

Labeling System

The labeling machine is designed to automate label application with high precision and speed. Suitable for various product formats and types, it ensures uniform labeling that complies with regulatory requirements. Easy to integrate into your production lines, it helps optimize processes while reducing human errors. Reliable and efficient, it guarantees perfect traceability and a polished product presentation.

Lidding Machine

The lidding machine is the ideal packaging solution to ensure airtight sealing and product safety for your food items. It applies a protective film over containers, providing optimal preservation while maintaining freshness. Easy to integrate into your production lines, it adapts to various container types and products. Fast and precise, this system optimizes your packaging efficiency while complying with the most stringent hygiene standards.

Improve Machine Availability with Our Hygienic Design

Acemia operates in the ready meals sector, in France and abroad, for both unpacked and packaged products. We can help you improve your production processes, from food preparation to tray placement and primary packaging. We offer automated handling solutions adapted to your products and their preparation.

HYGIENIC MATERIALS

100% stainless steel IP69K solution (motors, reducers, sensors, etc.)

- Hygienic Design+ finish: bead-blasted (ra: 0.8)

Easy to clean

Man-height equipment for easy access, inspection and cleaning.

- Tool-free removal of belts and accessories

- Storage cart available on request

NO WATER RETENTION

Open, inclined structure to avoid retention zones

No hollow tubings on any of our equipment

WATER SAVING AND

HYGIENE

Our CIP system ensures perfect cleaning of all parts in contact with the product.

You can program your own cleaning sequences (hot water, foam, disinfectant).